Wire Insights Podcast - Episode 5: Deep dive into our core products bearing steel wire and shaped wire

Welcome to Wire Insights, the podcast about the latest developments, innovations, and trends at voestalpine Wire Technology - from pioneering materials to sustainable production processes. Listen to our fifth episode on the topic of "Wire Excellence - Deep dive into our core products bearing steel wire and shaped wire".

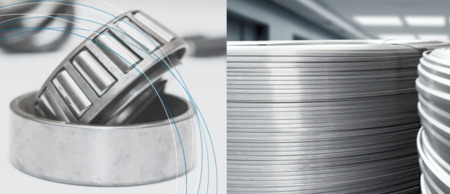

Deep dive into our core products bearing steel wire and shaped wire

The fifth episode of Wire Insights focuses on two key product areas of voestalpine Wire Technology: roller bearing steel wire and shaped wire. Experts Stefan Monschein and Bernadette Doppelhofer provide insights into technological innovations, quality strategies, and current developments.

They show how voestalpine Wire Technology achieves the highest standards in precision, resilience, and sustainability through state-of-the-art facilities, integrated production processes, and future-oriented research. Whether it's high-strength roller bearing wire or complex profile wire shapes, voestalpine Wire Technology is shaping the future of the wire industry with expertise and innovative strength.

Be part of the future of the wire industry - innovation begins with knowledge! Listen now!

-

(00:00 - 01:25)

Welcome to Wire Insights, the podcast of the latest developments, innovations and trends at voestalpine Wire Technology. From cutting-edge materials to sustainable production processes. Experience exciting insights into current projects that are revolutionizing the industry and find out how innovations made of wire are changing the world.

Whether you are a technology enthusiast, an industry professional or just curious about the future, this podcast is for you. Tune in and join us. Welcome to a new episode of Wire Insights.

In today's episode, wire excellence, a deep dive into our core products of bearing steel wire and shaped wire. We explore the innovation, precision and performance behind two of voestalpine Wire Technology's most essential product lines. Join us as we uncover what makes these wires the backbone of high-performance applications around the world.

To explore this topic, we are joined by two insightful guests who will share their expertise on the technology production and challenges surrounding these products. Get ready for interesting facts, practical insights and maybe even a few surprises from the world of wire. Now, I'm very pleased to welcome our first guest today, Stefan Monschein.

(01:26 - 01:39)

Mr. Monschein, it's great to have you with us on Wire Insights. Before we dive into the technical details, could you introduce yourself and tell us about your background and career journey at voestalpine Wire Technology?

(01:40 - 02:42)

Hello, I'm working at voestalpine Wire Austria since 2022 as an application engineer. In this role, I support various customers in the automotive industry, including those in the bearing industry, focusing on technical support, product development and ensuring the high quality standards for steel wire products.

Before joining voestalpine Wire Austria, I studied material science at Montan Universität Leoben, where I finished my master's degree in 2019. And after that, I worked as a PhD researcher for three years and completed my PhD in 2022. So my PhD work already was part of a joint research project with voestalpine Wire Technology's R&D department and focused on the development of micro-alloyed steels for high performance applications like chains and screws. So you could say that I was well prepared for my future role within voestalpine Wire Technology during my university career.

(02:43 - 04:46)

Okay, can you give us an overview of the key applications of ball bearing wires and roller bearing steel wires and why they are so crucial for these applications? Okay, so when we think about motion, so whether it's in a car, a wind turbine, a robot arm or even a household appliance, there's always one common element that keeps things moving smoothly and this is a bearing. So wherever something rotates, rolls or turns, there's almost always a bearing involved.

And inside these bearings you will find high precision components made from bearing steel wire. And the best known of these steel grades for instance is 100 chromium 6. So in a way, bearing wire is the silent backbone of motion in the automotive industry and industrial machinery and beyond. Ball bearing wires and roller bearing steel wires are used in highly demanding mechanical applications where dynamic loads, high rotational speeds and long service life are expected.

So these wires are crucial because the final bearing products must meet extremely high standards for fatigue resistance, dimensional precision and especially wear resistance. And all of this is only possible if the starting material, the wire, is of the highest metallurgical and surface quality. So we at voestalpine Wire Technology have traditionally been a strong supplier for taper and cylindrical bearing applications.

However ball bearing applications so far have have long been dominated by block casting producers. And this changed with the commissioning of our new continuous casting plant with the jumbo format which allowed us to enter this high-end segment of ball bearing applications as well. And thanks to advanced features like electromagnetic steering and soft reduction this plant gives us the ability to produce a clean and highly homogeneous microstructure which is essential for meeting the stringent inclusion and segregation requirements in ball bearing steels.

(04:47 - 06:26)

How does voestalpine Wire Technology ensure that there are wires for ball bearings and roller bearings meet the highest quality standards? So in addition to the before mentioned points with the continuous casting technology for ball bearing wire specifically we developed a unique heat treatment route to optimize the microstructure. And on top of that we also apply non-destructive testing methods like ultrasonic and eddy current inspection to guarantee defect-free surfaces and internal structures. So thanks to this comprehensive quality strategy we became the first European supplier qualified for ball bearing applications from the continuous casting route which is a major milestone for our company and also our customers.

Another big advantage we have is that voestalpine Wire Technology controls the entire value chain in-house. So that includes the steel making at voestalpine Stahl Donauwitz, the wire rod production at voestalpine Wire Rod Austria, the wire drawing at voestalpine Wire Austria and also our R&D department. So all located close together within our company network and also geographically.

So this allows us for fast feedback loops, tight process control and also continuous improvements. And our corporate values, quality, sustainability, innovation and flexibility are embedded in every step of our process and I believe that's one of the key reasons for our success in such a demanding segment like ball bearings and bearing applications.

(06:27 - 08:28)

Okay, what future trends and developments do you see in the field of bearing technology? The bearing industry is of course also evolving continuously.

One clear trend is the move toward a zero defect philosophy. So we see that what used to be acceptable defect rates are no longer tolerated especially in high performance applications. This puts even more pressure on material producers to ensure this high quality from the very beginning.

At the same time sustainability is becoming increasingly important. So customers and end users are pushing the whole market for lower CO2 emissions across the entire supply chain and this aligns well with our plans. So from 2027 onwards voestalpine will introduce an electric arc furnace as part of our decarbonization strategy and this will allow us to produce high quality bearing steel with a significantly lower carbon footprint.

I think another important development is digitalization and predictive quality control. By combining real-time process monitoring with advanced AI analytics we aim to monitor deviations before they occur and this will also be critical in meeting the rising expectations of our customers in terms of quality and consistency. And finally I would say collaboration will be more important than ever.

So bearing manufacturers increasingly want material suppliers who can support them not just with high quality products but also with know-how, joint development projects and rapid responses to changing requirements. So in summary high performance bearing wires require excellence in every production step from steel making to final inspection in the drawing facility. We at voestalpine Wire Technology have the big advantage to control the whole process chain in-house and we are very proud to be shaping the future of this field together with our partners and customers.

(08:29 - 08:38)

Thank you so much for sharing your insights and giving us a great overview of your work and experience at voestalpine Wire Technology.

(08:39 - 08:54)

Now I'm delighted to welcome our second guest Bernadette Doppelhofer. Bernadette it's a pleasure to have you here. Could you also take a moment to introduce yourself and share a bit about your role and your journey at voestalpine Wire Technology.

(08:55 - 09:26)

Yeah hello Dieter, thank you to be here. Yeah unbelievable I have my 10 year anniversary now here at voestalpine.

I started here in St. Peter at Wire Rod Mill for process engineering and then my journey goes to another direction to the sales department and at the moment I'm working in Bruck in the voestalpine Wire Austria and support there as a kind of hybrid application and sales manager.

(09:27 - 11:02)

What technological innovations has voestalpine Wire Technology introduced in recent years in the field of profile wire production? So in recent years voestalpine Wire Technology has been focusing on making our profile wire producing even better through technology. Two key developments really stand out.

The most important one is that we have commissioned a new cold profile rolling machine our KPWA as we call it in Bruck. This isn't just a simple upgrade it's a significant expansion of our capabilities. This new facility allows us to produce wire across sections starting from a much smaller size of about two square millimeters. What's particularly exciting is the special height to width ratio this new line can achieve opening up possibilities for entirely new applications of our profile wires. Beyond just size this new machine also brings about improvements in the surface quality of the wire and very tight tolerances as well. This is crucial because of our customers demand.

Finally this boosts our production capacity and significantly expands our portfolio in Bruck. We are a big player of providing complex profiles and with this new system we will continue to discover new areas of applications in profile wire technology.

(11:03 - 11:54)

How does voestalpine ensure that their wires meet the highest quality standards? Quality is absolutely paramount for us at voestalpine Wire Technology.

It starts with the careful selection of high grade raw materials. Then throughout the entire production process from voestalpine Donowitz from the steel plant through the wire rod mill we have stringent quality control measures in place including automated checks and manual inspections by our expertised technicians. We fulfill strict international standards and certifications.

Beyond that we believe in continuous improvement. We constantly analyze and processes and customer feedback to identify areas where we can further enhance our quality.

(11:55 - 14:50)

What future trends and developments do you see in the field of profile wire technology? All right let's dive into three future trends what I want to mention.

Surface defect for zero failure strategy and higher strength and at least weight saving and downsizing. A crucial trend is the growing emphasis on surface detection for zero failure strategy. Our customers rightly demand the highest level of reliability and this means the requirements are increasingly moving in the direction of defect-free wire.

We are investing heavily in advanced sensor technologies and inline inspection systems that can detect even the smallest surface failures in real time. This allows us to identify and eliminate any potential issues working towards a zero failure approach. Another trend is that the demand for higher strength in profile wire continues to rise.

Often this needs to be achieved without the added complexity and cost of for example after treatment. This requires ongoing advancements in material science and or cold forming processes to create alloys and shaping techniques that deliver exceptional strength directly. Finally we are observing a clear trend towards downsizing as customers require ever smaller and more complex wire profiles for their compact applications.

This downsizing often goes hand in hand with the demand for weight saving particularly in industrials like automotive or aerospace where every gram counts. To meet these challenges we are constantly innovating our production techniques to achieve these complex geometries with tighter tolerances and as I mentioned at the beginning our latest machine the cold profile rolling machine hitting the tooth of time. It's crucial to understand the realizing these advancements.

Producing ever smaller and more challenging profiles with increasingly demanding properties is only possible through the deep experience and expertises of our engineering team. Our ability to constantly push the boundaries of profile wire technology relies heavily on the knowledge and dedication of our engineers. They are driving by a shared goal to provide our customers with the absolute best possibility solution for the specific needs they want.

This is our more or less customer-centric mindset and yes we are really good team.

(14:51 - 15:29)

Before we wrap up we'd like to hear what you're currently working on. Could you each give us a quick insight into the projects or developments that are keeping you busy right now, Ms. Doppelhofer? Yeah at the moment a major challenge is the commissioning of very small complex profiles with extremely high strengths.

We are really pushing ourselves at the moment to the to the limits. Sometimes we are with success and sometimes we fail. Then we go back to the start and try again with another idea.

But most of the time we are successful.

(15:30 - 16:20)

Thank you. Mr. Monschein, what keeps you busy right now? So first of all also thank you from my side for having the chance to to speak here today.

In my role as an application engineer I'm not only involved in the field of bearing steels but also support a wide range of automotive customers who use our cold trading grades. Currently I'm engaged in several exciting internal optimization projects as well as numerous customer projects and maybe one highlight I would like to mention is a pioneering project where we at voestalpine Wire Austria are producing drawn wire with diameters below one millimeter for the first time with the the big aim to establish a foothold in the indian market. So quite challenging but also very exciting times.

(16:21 - 16:45)

Thank you both for these fascinating insights and for taking the time to share your expertise with us today. It's been a real pleasure having you on Wire Insights. And to our listeners thank you for tuning in.

If you enjoyed this episode don't forget to share it with colleagues or friends. Until next time stay curious and keep exploring the world of wire technology.

Bearing wire for high-performance applications

Stefan Monschein is an application engineer at voestalpine Wire Austria and supports customers from the automotive and roller bearing industries. He explains that roller bearing wire is indispensable in moving applications such as vehicles or wind turbines. The high resilience and precision of the wire products are crucial for the service life of the bearings.

A technological breakthrough was the commissioning of a new continuous casting line that enables particularly pure microstructures. This is complemented by special heat treatments and non-destructive testing methods. Complete control of the value chain within the company ensures fast feedback and high quality.

Monschein sees trends such as the zero-defect strategy, CO₂ reduction through new furnace technologies, and the use of AI for quality control. He is currently working on a project to manufacture thin wires for the Indian market.

With advanced technologies such as electromagnetic stirring and soft reduction, made possible by the commissioning of our new jumbo continuous caster, we can produce a clean and highly homogeneous microstructure. This is critical to meeting the stringent inclusion and segregation requirements for bearing steel.

Innovation in shaped wire production

Bernadette Doppelhofer has been with voestalpine Wire Technology for ten years and now works in a hybrid role in applications and sales. She reports on the new cold profile rolling mill in Bruck, which enables smaller and more complex wire profiles to be produced with high precision. The mill improves surface quality and significantly expands the range of applications.

At voestalpine Wire Technology, quality begins with the selection of high-quality raw materials and is ensured through automated and manual testing. She cites three key trends: surface detection for zero defects, higher strengths without post-treatment, and downsizing for compact applications.

It is currently working on particularly small profiles with high strength - an area that requires a great deal of technical expertise and creative solutions.

The commissioning of our new profile rolling line marks a significant advance in profile wire technology: We now produce cross-sections from 2 mm², achieve better surfaces, tighter tolerances and open new applications thanks to the special height-width ratio. At the same time, we are expanding our capacities and our product portfolio - a real milestone for voestalpine Wire Technology.

FAQs about podcast episode 5

-

Rolling bearing steel wire is a high-precision wire used in ball and roller bearings—for example, in vehicles, wind turbines, or robots. It must be resilient, wear-resistant, and dimensionally accurate.

-

The jumbo-sized plant enables a particularly pure and homogeneous microstructure. This allows voestalpine Wire Technology to meet the high requirements for ball bearing steels and open up new market segments.

-

Through a combination of state-of-the-art heat treatment, non-destructive testing (ultrasound, eddy current), and complete control of the value chain - from the steel mill to the wire drawing plant.

-

Important trends include the zero-defect strategy, CO₂ reduction through new furnace technologies, digitalization and AI-supported quality control, as well as close cooperation with customers.

-

Profile wire is a specially shaped wire with complex cross-sections that is used in applications with high requirements in terms of geometry, strength, and weight—e.g., in the automotive and aerospace industries.

-

The new cold profile rolling mill (KPWA) in Bruck enables the production of particularly small and complex profiles with high precision and improved surface quality.

-

By investing in sensor technology for surface detection, developing high-strength materials without post-treatment, and continuously optimizing manufacturing techniques.

🎧 Thank you for listening to Wire Insights

Wire Insights is the podcast for anyone interested in sustainable technologies, innovative production processes, and forward-looking developments in the wire and steel industry. Stay tuned for the next episode with more exciting insights from the world of wire technology!