Mechanical engineering

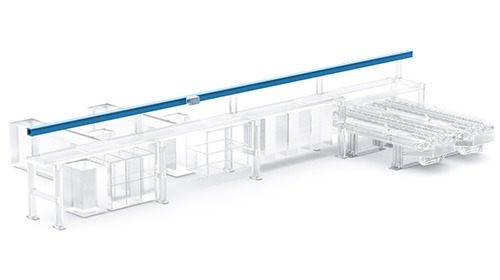

VTS®-edgeTubes - the product of choice for mechanical engineering.

The seamless, hot-rolled, square and rectangular hollow sections from voestalpine Tubulars are ideally suited for use in mechanical engineering due to their product properties. They complement the portfolio of our circular hollow sections perfectly.