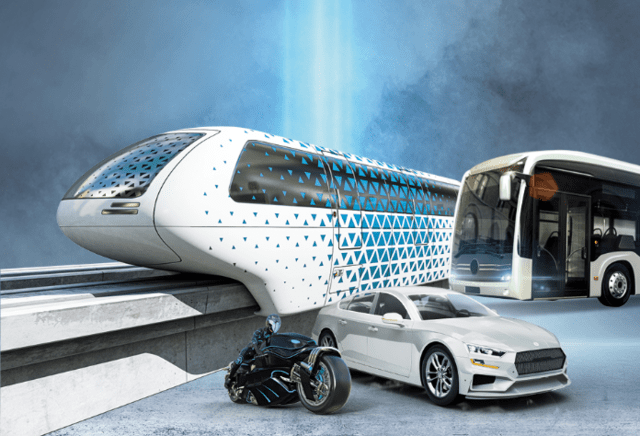

The familiar topics of light-weight design and safety in car bodies will continue to gain significance with increasing electromobility. The need for highly efficient electrical steels for rotors and stators in the drive train is new for many customers. While today more than 100 electric motors are found in every modern car, the manufacture of pre-materials for such motors was less challenging. The new drive motors have changed the picture dramatically.

In the following series, "Electromobility at voestalpine," we will be showing to you how we have prepared for the age of electromobility with investments amounting to €150 million. The following article is the beginning of a journey filled with articles on the topic of electrical steel for electric mobility and insights into the technical and application-oriented requirements of this special steel product. Learn more about our solutions for the high-frequency range, our developments in the field of high-strength electrical steel, and gain insights into the methods we use to achieve the required polarization.

Why is steel needed in an electric motor?

An electric motor converts electricity from a battery or a fuel cell into kinetic energy and cannot be operated efficiently unless the motor core consists of electrical steel laminations. Electric motors are 90% efficient, which makes it even more important to reduce consumption by introducing electric drives for components such as steering systems and brake boosters, which were previously driven by mechanical or hydraulic systems.

Today's conventionally driven cars and trucks are frequently equipped with more than 100 electric motors, the total weight of which averages 50 kilograms per vehicle.

Electrical steel made by voestalpine.

Our decision to accompany the processes of automotive electrification is a strategic one that was highlighted by the startup of one of the world's most modern electrical strip production facilities in 2014. isovac® is the electrical steel made by voestalpine and stands for highest energy efficiency. Close collaboration with our customers from the automobile component supplier industry has made us one of the leading suppliers of electrical steel for electromobility in the European market. isovac® already drives a large number of cars and trucks made by European manufacturers.

Maybe you are already driving a car with a heart made of isovac® and are happy to know that you will quietly reach your destination in peace and safety and without producing any emissions.