Extended Maintenance Intervals

Unplanned stoppages are one of the main obstacles to achieving high OEE. The following Case Study is just one of many real-world examples that show how our approach can help improve OEE in high-pressure die casting.

The Results at a Glance

TOOL LIFE:

+41.9% (from 62,000 to 88,000 cycles)

a

MAINTENANCE INTERVAL:

+87.5% (from 8,000 to 15,000 cycles)

A Case-Based Approach

From Data to Performance

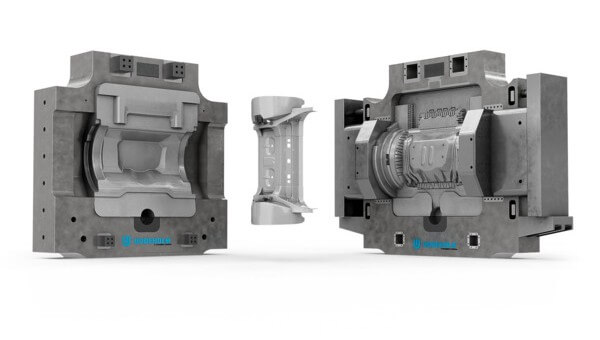

In the highly competitive field of automotive die casting, an OEM supplier encountered recurring failures on a critical insert used for producing structural components made from a Magnesium Alloy.

Originally manufactured in 1.2344 ESR with a working hardness of 43-45 HRC, the insert reached end of life after only 62000 cycles while maintenance was required every 8000 cycles. the reasons were strong heat checking and washouts.

Directly impacting OEE through increased downtime and maintenance costs.

The Scenario

INSERT DIMENSION

1420 x 575 x 395 mm / 1420 x 475 x 490 mm

GRADE – HRC

1.2344 ESR – 43-45 HRC

TOOL LIFE

62 000 cycles

FAILURE REASON

Washouts, Heat Checking

MAINTENANCE INTERVAL

8 000 cycles

Data-Based Methodology

The process begins with the collection of detailed technical information.

Examples of Required Data Points:

Component Characteristics

includes alloy type, geometry, and wall thickness to identify areas exposed to high thermal stress and potential wear.

Casting Machine Setup

information on machine force and pressure helps us understand the mechanical and thermal loads acting on the die

Spraying Technology

the lubrication method used affects thermal shock and surface wear—key factors in die degradation.

Cooling System Design

cooling media, temperature, and channel layout are analyzed to detect thermal imbalances and optimize heat dissipation

Cycle Parameters

cycle time, contact duration and casting speed influence thermal fatigue and tool life.

Thermal Behavior

surface and core tempera ture trends reveal thermal gradients that contribute to damage mechanisms like heat checking.

From Insight to Impact

A data-driven approach ensures that each solution is engineered in response to specific process conditions. Based on this analysis, a material upgrade to Uddeholm Dievar® was implemented, increasing the working hardness to 46-48 HRC. Dievar® is a hot-work tool steel with excellent toughness, ductility, and heat resistance, ensuring long tool life and low crack risk. This, combined with a sharper understanding of thermal management and wear mechanisms, yielded significant results:

The Performance

INSERT DIMENSION

1420 x 575 x 395 mm / 1420 x 475 x 490 mm

GRADE – HRC

Uddeholm Dievar® – 46-48 HRC

TOOL LIFE

88 000 cycles

MAINTENANCE INTERVAL

15 000 cycles

TOOL LIFE

+41,9% *

MAINTENANCE INTERVAL

+87,5% *

This case illustrates how a methodical approach—grounded in process data, material science, and application-specific engineering—can deliver measurable gains in OEE and sustained production stability.

* Performance growth in percentage

Downloads

Contact voestalpine High Performance Metals Canada for further information

Fields marked with * are mandatory.