BÖHLER W302 ISODISC

BÖHLER W302 ISODISC is a 5% chromium steel and corresponds to material number 1.2344 (X40CrMoV5-1). This common tool steel has good hot toughness as well as a high hot hardness and a high resistance against heat-checkings. The combination of these properties makes it a standard choice in extrusion, forging and low-pressure die casting. This material is also available as W302 ISOBLOC which is a remelted grade with improved cleanliness, homogeneity and toughness.

Product Features:

- Toughness & Ductility: good

- Wear Resistance: high

- Hot Hardness (red hardness): high

- Polishability: good

- Thermal conductivity: good

- Micro-cleanliness: good

Applications:

- Blow Molding

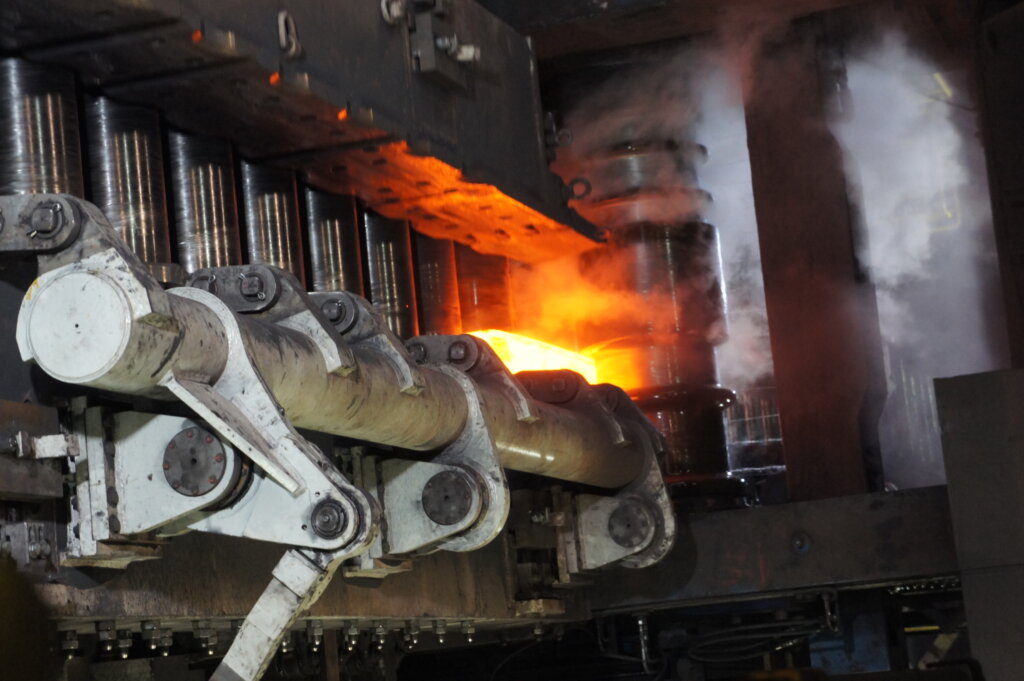

- Extrusion

- Forging

- Low Pressure Die Casting (LPDC)

- High Pressure Die Casting (HPDC)

- Injection Molding

- Hot Stamping

- Progressive Forging

Technical Data

Chemical Analysis

| C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|

| 0.39 | 1.10 | 0.40 | 5.20 | 1.30 | 0.95 |