Focus on Sustainability

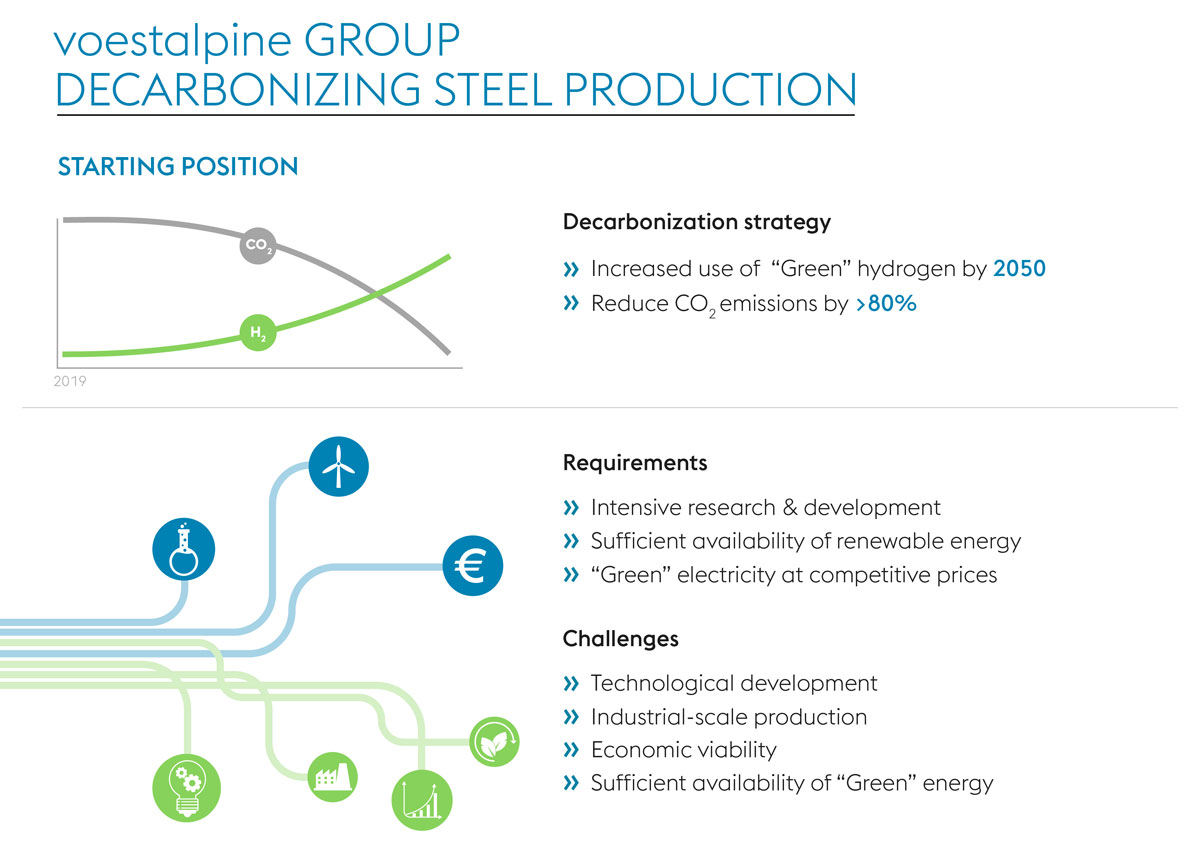

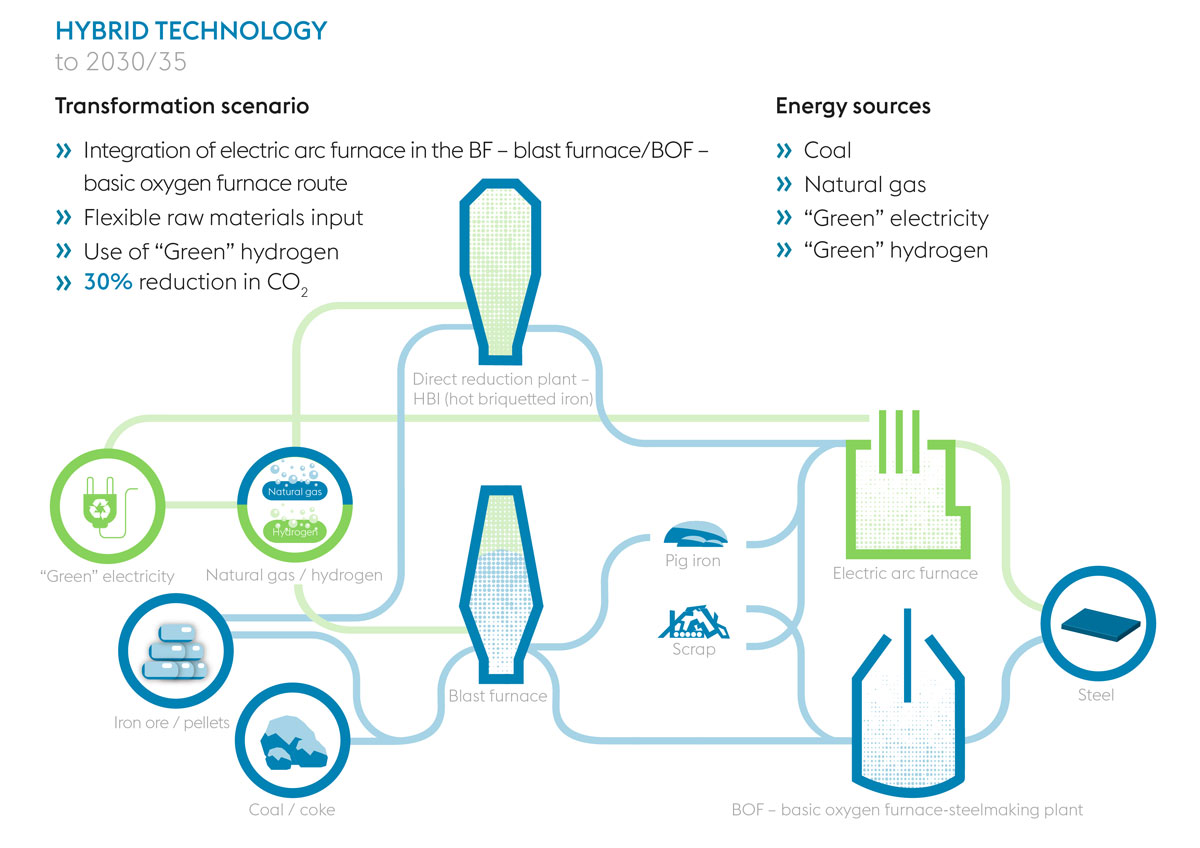

Everybody is talking about sustainability, but what does it mean? And how is the production of iron and steel related to it? The concept of sustainability is as much a key element of voestalpine’s actions as are resource conservation and life cycle assessments.

- 3