Recycling logistics for green steel: Where does the scrap for the EAF come from?

- 6

In addition to the construction work for the plants and their peripherals, the power and media supply, the complete digitalization of the process, and many other topics, the supply of raw materials for green steel production is an essential part of the transformation. With the ramp-up of electric arc furnaces at the Linz and Donawitz sites, around 2.2 million tons of high-quality scrap will be needed from 2027 onwards – double the current amount.

The production of green steel requires different types of scrap, which vary in origin and composition.

a) Pre-consumer scrap (new scrap):

b) Post-consumer scrap (old scrap):

Old scrap covers the entire range of end-of-life steel products – from refrigerators and water boilers to radiators. Scrap metal dealers also take end-of-life railway wheels, old vehicle bodies, and carrier scrap. Much of this scrap is shredded and, in the best case scenario, analyzed directly on the conveyor belt. These processes have been developed in recent years and now enable high-quality shredder scrap with a high degree of purity and accurate analysis. Recycling scrap is more expensive due to technology-assisted separation and shredding, but it plays an enormously important role in protecting the climate and ensuring process reliability.

This refers to the additives copper, chromium, nickel, molybdenum, or tin, which can influence the mechanical and technological properties (e.g., yield strength, tensile strength, toughness, etc.).

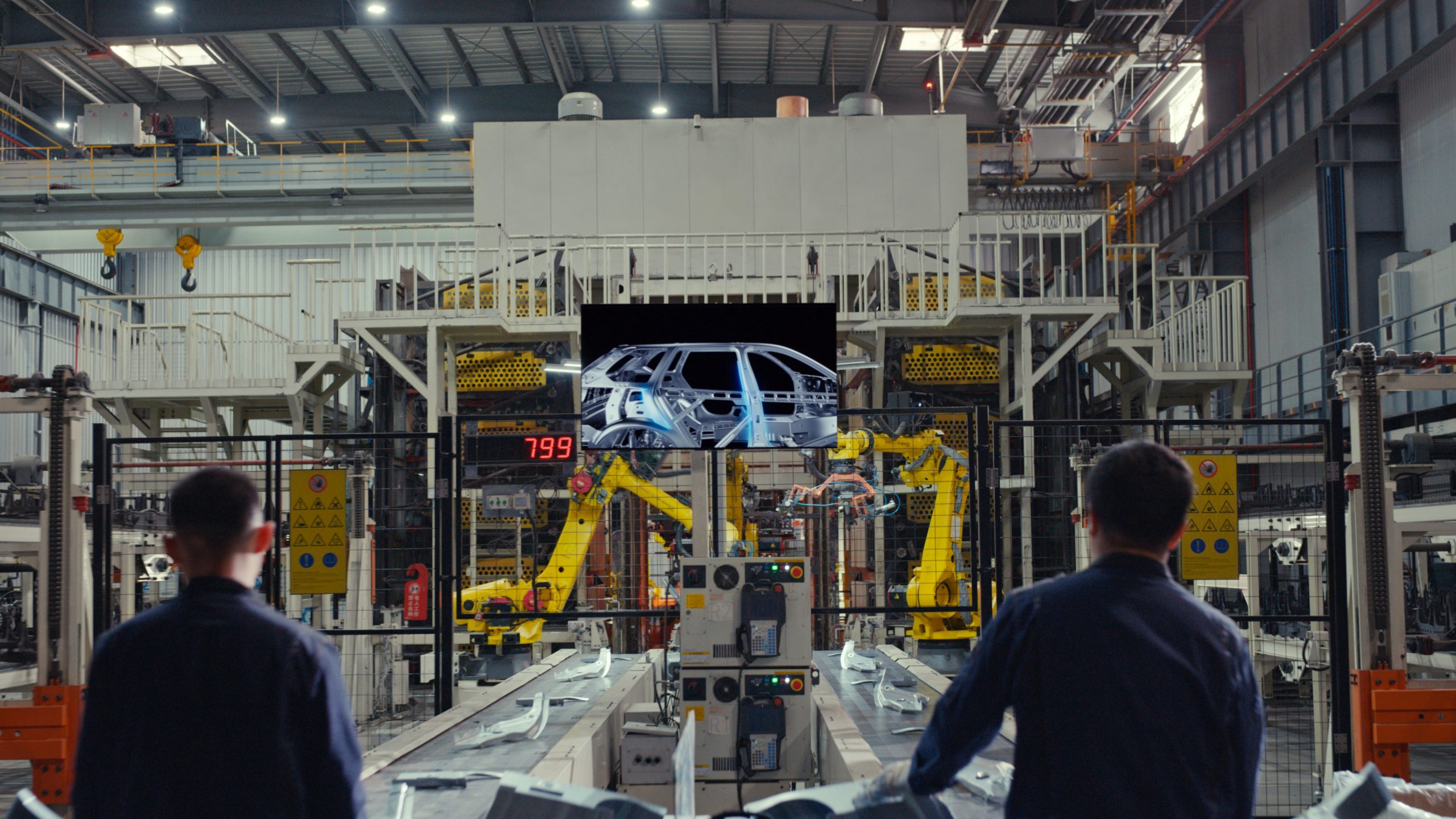

The contents of press shop scrap (pre-consumer scrap, new scrap), which is produced, for example, by cutting out window areas in the production facilities of our automotive customers in Germany, are well known. We return this scrap to our processes in closed cycles. We deliver our coils for their car body production directly to the plants by rail and take the valuable steel scrap back with us on the return journey. This system, known as the Bavaria Shuttle, ensures a seamless material cycle.

The Bayernshuttle is a closed circular rail system that has been in operation for three years, serving the southern German automotive industry on the route from Linz to Regensburg (BMW), Dingolfing (BMW) and Ingolstadt (Audi) – five times a week.

But it is not only the automotive industry that is part of our cycle. We strive to implement such closed-loop concepts with many of our customers, and we also integrate traditional ironmongers into our comprehensive scrap logistics system. Central hubs such as the Ennsdorf scrap hub store, sort, and prepare up to one million tons of scrap metal for onward transport every year. This hub is connected by three modes of transport—truck, rail, and ship—enabling flexible and sustainable logistics.

Special lightweight “Scrap on track” wagons are used to transport large quantities of scrap, offering a train load advantage of approximately 30% and featuring a structure and platform made from greentec steel Edition steel. From 2027, two to three freight trains with 18 wagons each will run daily from the scrap hub to Linz and Donawitz. The sorting of scrap is increasingly supported by digital systems and machine learning, which record and categorize scrap according to quality, weight, and other parameters.

Best possible performance at the Ennsdorf scrap hub:

This scrap shuttle service on the rail line between Linz and Ennsdorf currently operates twice a week (Tuesdays and Saturdays) with special electric and diesel locomotives in the optimal batch size of 18 wagons.

The following are also necessary for the smooth and effective transport of scrap by rail to the Linz plant: a high-performance rail line, additional unloading tracks, 34,000 m² of new service roads, and an 800 m long, automated conveyor line, which will also supply the electric arc furnace with raw materials from 2027.

In the future, 2.2 million tons of scrap per year or six external scrap trains per day with a total length of more than 1,500 m can be handled over a length of 300 meters. We are also working on the electrical supply, the relocation and new installation of signal and media lines, and adjustments to the camera and lighting systems.

Our scrap purchasing strategy is based on reliable pillars:

To ensure reliable disposal for our partners and a seamless supply for us, we are continuously setting up new scrap hubs together with our recycling partners – for example, in Budweis, Regensburg, Vienna, and Knittelfeld. This keeps the supply stable even in the face of logistical challenges and reduces the ecological footprint of steel production – thanks to closed cycles, efficient transport routes, and digital sorting.

The use of electric arc furnaces (EAF) for green steel production will double the amount of external scrap. Part of our responsible scrap logistics involves regular scrap collection from our customers and high-quality, efficient scrap processors. This allows us to close the sustainable steel cycle, secure production, and actively contribute to climate protection.

Scrap is a major issue when it comes to reducing emissions and sustainability in steel production. The more scrap is used, the lower the CO2 emissions. Reusing the recyclable material therefore conserves resources and is precisely the step we need to take to mitigate the increasingly noticeable consequences of climate change. Technology and metallurgy make a valuable contribution to manufacturing high-quality products and protecting the environment at the same time.

We can already see that multi-stage sorting offers great potential. The scrap is first cleaned using conventional methods such as magnetic separation. Only in the final step do LIBS or XRF separate the wheat from the chaff.

It is impossible to imagine modern cars without features such as electric windows or electric seat adjustment. Numerous electric motors are required for these functions and one of the main components of these motors is copper wire. During conventional processing, the steel scrap is contaminated with copper, for example, and the content of this disruptive element in the scrap as a raw material is therefore constantly increasing. These interfering elements can no longer or only partially be removed from the steel production process, which limits the amount of valuable raw material that can be recycled.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.