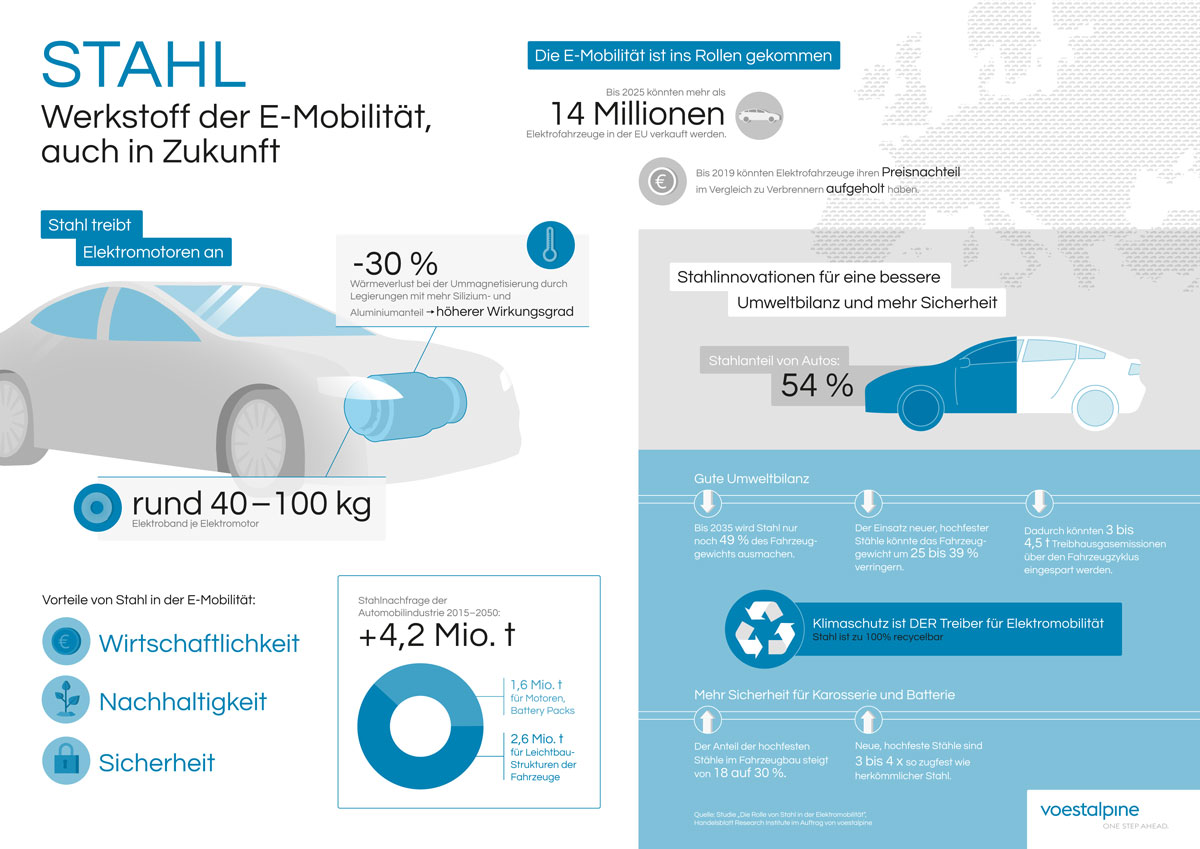

The role of steel in electromobility

A study conducted by the Handelsblatt Research Institute on behalf of voestalpine provides answers to questions about safe and sustainable automobility in the future–and the role of steel with respect to the motor, car body, battery, and life cycle assessment.

- 22 Mar, 2019

- 7