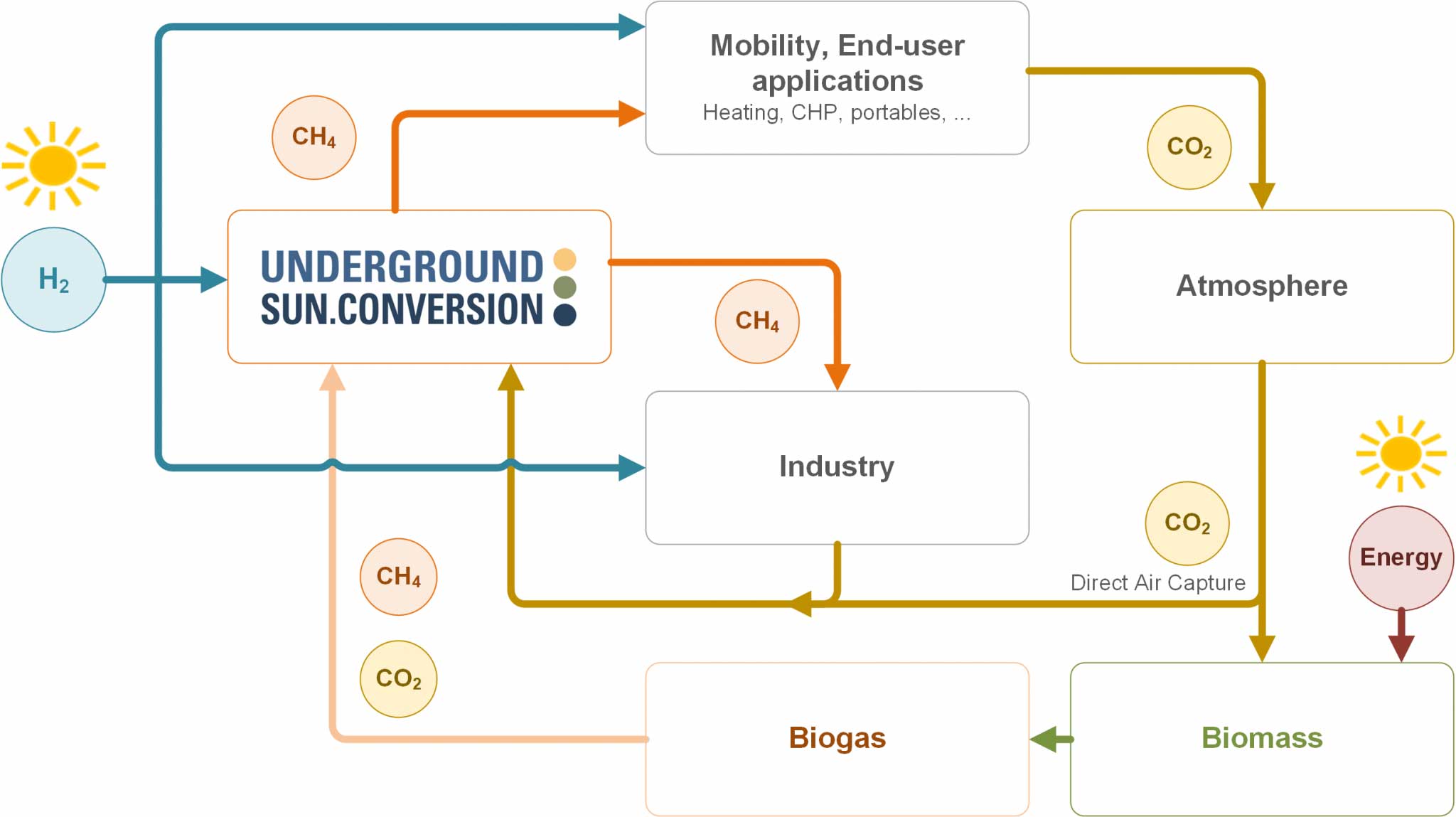

Sensible CO2 recycling

Together with a research team from K1-MET, voestalpine is investigating new ways to prevent climate-damaging emissions. In the future, CO2 that is produced during steel production—technologically unavoidable—could be converted into a valuable energy source deep in the earth.

- 10 Feb, 2023

- 3