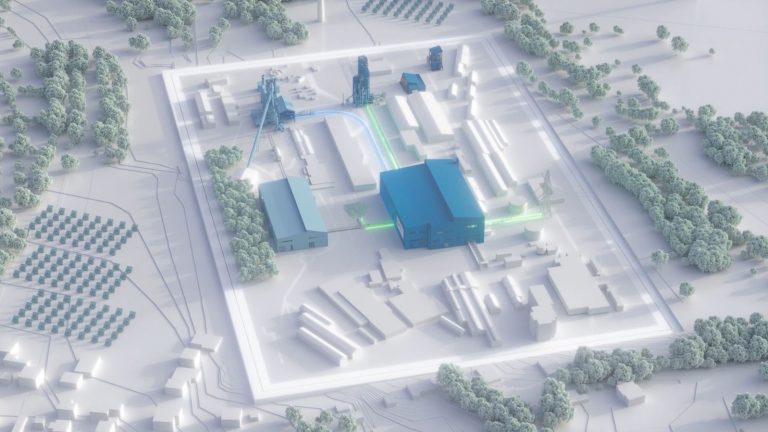

Research projects for green steel production

At voestalpine, we are charting the way ahead for green steel. Our continuous research and development in advanced technologies supports the implementation of the “carbon-free by 2050” goal to 2030 and beyond.

- 05 Jun, 2023

- 5