Recycling miracle steel: How scrap is turned into #FavoriteMoments

- 4

What should you do when your old tool, watch, razor or car has had its day? The best thing to do is return it to the retailer or dispose of it properly. This keeps the material in the cycle and turns it into a valuable raw material for a new product. Every sustainable measure contributes to a healthy climate for future generations – and the measures taken by entire industries have a far-reaching effect.

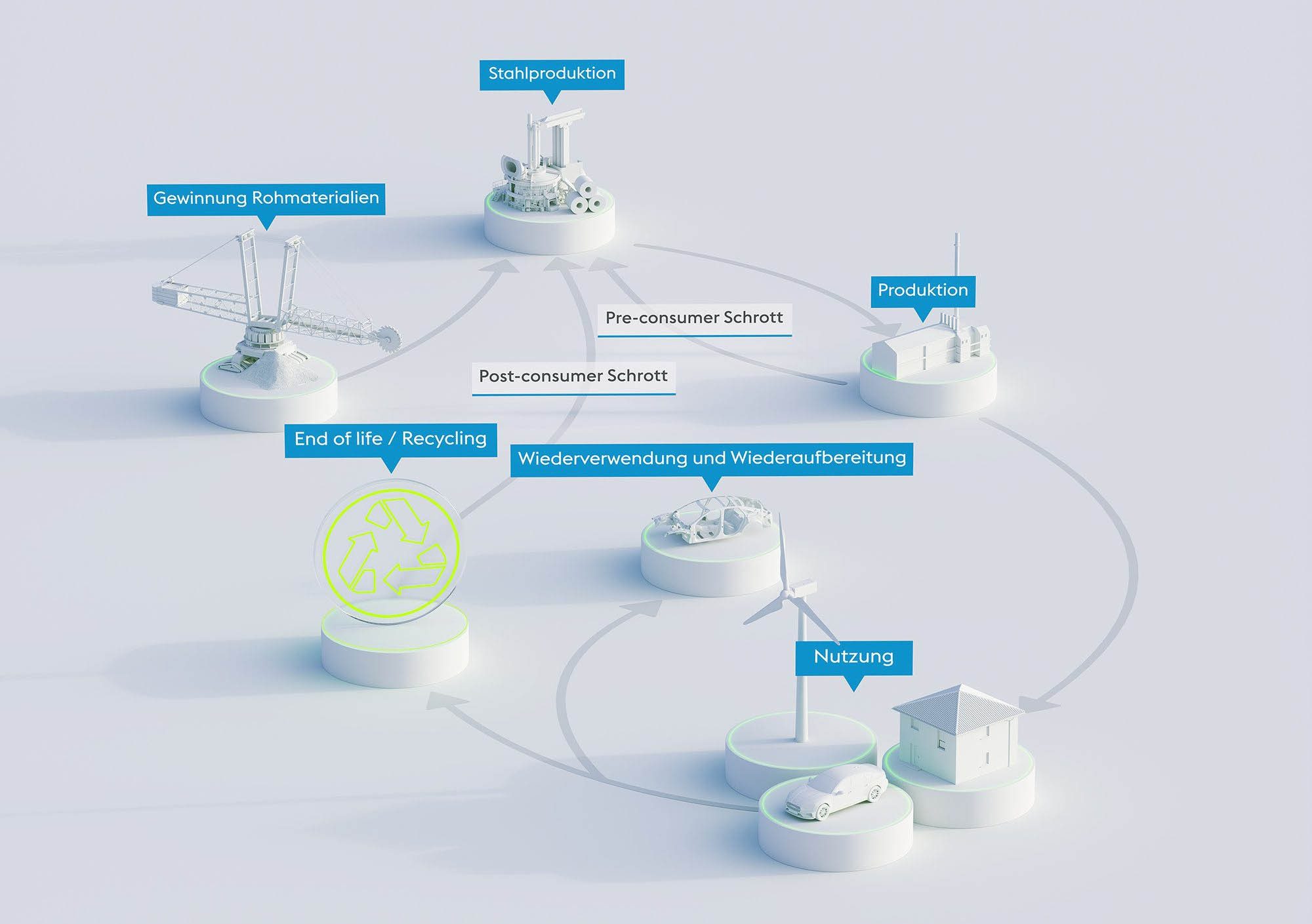

Steel is a multi-talented material that enables weight-saving and durable products that are easy to repair and ultimately 100% recyclable. Once produced, steel – whether via the classic blast furnace route or via a CO2-reduced green process – reduces the CO2footprint every time its service life is extended and every time it is recycled. High-strength components in particular make a valuable contribution to the CO2-relevant steel cycle.

Even in production, steel has a comparatively positive CO2emissions balance. Compared to other materials, steel releases significantly fewer greenhouse gas emissions.

For us, scrap is a valuable resource for which our employees develop ways and means of producing high-quality steel again. This sustainable cycle results in high-quality watches, beautiful furniture, safe aircraft parts for vacation and business trips, efficient rails and switches for a safe journey to work or school, bridges over valleys and rivers, photovoltaic substructures for green electricity and much more. In addition to all these products, the value of scrap is particularly impressive in vehicle construction.

greentec steel is currently the most important climate protection program in Austria. However, we are already working continuously to reduce the CO2 footprint in the production of high-tech steel materials that our international customers can use for their products in an environmentally conscious manner. Scrap plays an important role in this. But first things first – let’s look at production first.

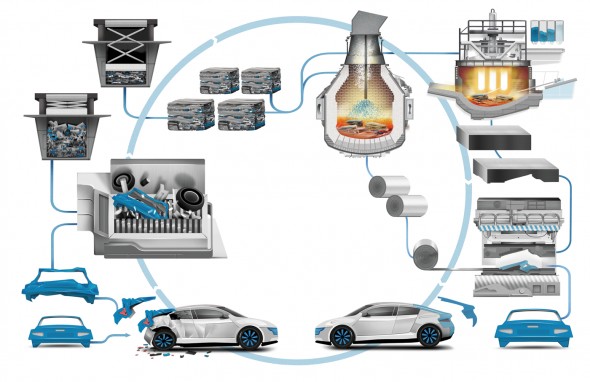

A brand-new car should contain scrap metal? For us, this is as clear as day, because scrap material is an important part of the process in the manufacture of vehicles and specifically in the production of steel for automotive components. Scrap steel is then used to produce components for new cars, such as tailgates, roof parts or spare parts. We will continue to increase the proportion of steel scrap in premium steels for global industries in the future.

Our projects with customers in the automotive industry show that scrap can be turned back into something valuable for everyone to see. They clearly show where we are already using the circular economy in practice.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.