voestalpine Wire Technology produces wire rod for a wide range of industrial applications, including construction, automotive, and mechanical engineering. Production takes place at the world's most modern wire rolling mill in St. Peter/Freienstein (Austria), with tight dimensional tolerances and defined quality standards.

The portfolio includes wire rod for cold heading and cold extrusion products, roller bearing steel, springs, chains, welding consumables, and customized special solutions. Technological equipment and material-related expertise enable the precise implementation of customer-specific requirements.

✔ From ore to wire

✔ 400+ steel alloys

✔ Own R&D facilities

✔ CO2 reduced processes

Applications of wire rod

Cold heading and cold extrusion ›

- screws

- bolts

- fasteners

Rolling bearing steel products ›

- high-strength components for ball, roller and needle bearings

Springs and spring wire solutions

- chassis springs

- safety components

- mechanical elements

- basis for arc

- submerged arc

- gas-shielded welding wires

- hoist chains

- mining chains

- snow chains

- ship chains

Customized products made of wire rod

- Other high-performance applications on request - we will be happy to advise you

Your advantages with voestalpine Wire Technology

- Wide range of dimensions and materials: wire rod from 5 mm to 52 mm and over 400 steel alloys, including special and high-performance steels.

- Excellent forming properties and surface quality: Thermomechanical rolling for optimum formability, narrow diameter tolerances and the best surface quality.

- Individual surface and heat treatment: Customer-specific combinations of further treatments, e.g. pickling, phosphating, polymer coating, soft annealing.

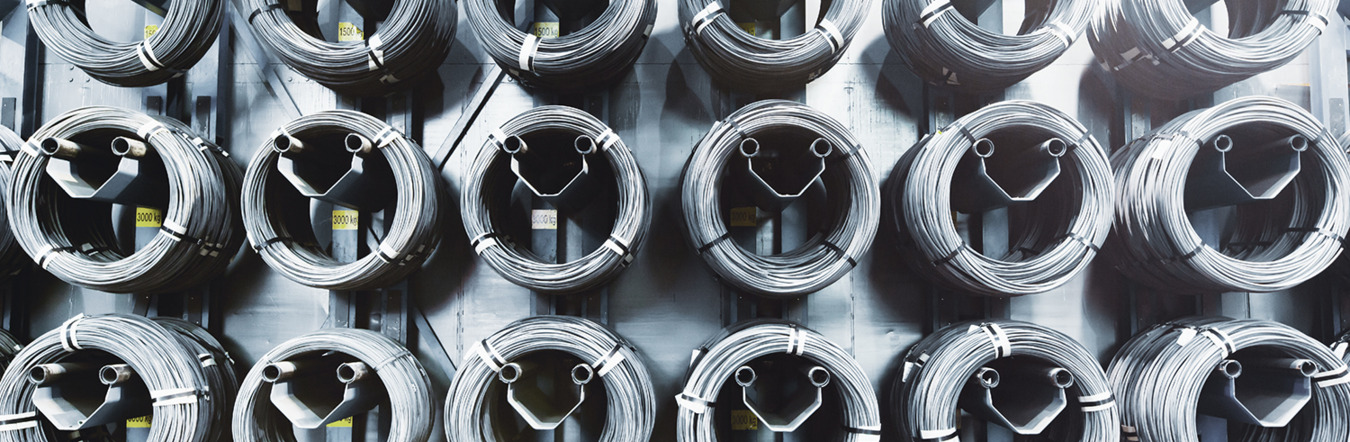

- Flexible ring sizes and efficient logistics: Ring weights of up to 3,000 kg enable maximum efficiency in further processing and transportation.

- Highest quality and sustainable production: State-of-the-art systems, continuous quality assurance (ISO, IATF) and energy-efficient, environmentally friendly processes.

FAQ: Frequently asked questions about wire rod

-

As a wire rod manufacturer and supplier, we supply wire rod in the range from 5 mm to 52 mm – individually tailored to your application.

-

Pickling, phosphating, a phosphate-free coating, polymer-based coatings, liming, soaping or combinations of these processes are possible.

-

More than 400 material variants, including micro-alloyed, dual-phase and AFP steels, precisely tailored to your requirements.

-

Yes, we also offer sample batches and small quantities for development projects or special parts.

-

Our integrated value chain enables complete traceability of all process and test parameters.

-

Yes, thanks to our stable processes and tight diameter tolerances, direct further processing of wire rod is possible in many cases, depending on our customers' product and process. This means that cost-intensive intermediate steps can be saved.

-

Many standard designs are available at short notice. We produce special dimensions flexibly by arrangement.

-

Yes, our R&D team supports you in the development of new alloys and product tests. Our materials experts will also provide you with individual and application-specific advice on material selection.

-

Our products meet international standards such as ISO, EN, ASTM, JIS - including specific test and acceptance certificates.

-

Depending on your requirements, as coils, spools or on crown.

-

High-quality raw material enables excellent dimensional accuracy, surface quality, and formability of the wire rod. It is crucial for subsequent processing, e.g., by drawing, coating, or welding.

-

The process begins with the raw material, which is heated and formed into wire in the rolling mill. This is followed by coil winding, coil handling, quality assurance, annealing, pickling, and storage. More about the wire rod production process.

Do you have a new project that requires wire rod?

Our experts will be happy to advise you and find the right solution for your requirements!