voestalpine Steel & Service Center Group

The cut-shape facility of the voestalpine Steel & Service Center Group is a full-service supplier that produces high-quality cut shapes and cut sheets from heavy plates and hot-rolled strips. Maximum security of supply, our dedication to delivery deadlines and our proximity to the customer mean a lot to us: Our solutions provide added value for our partners.

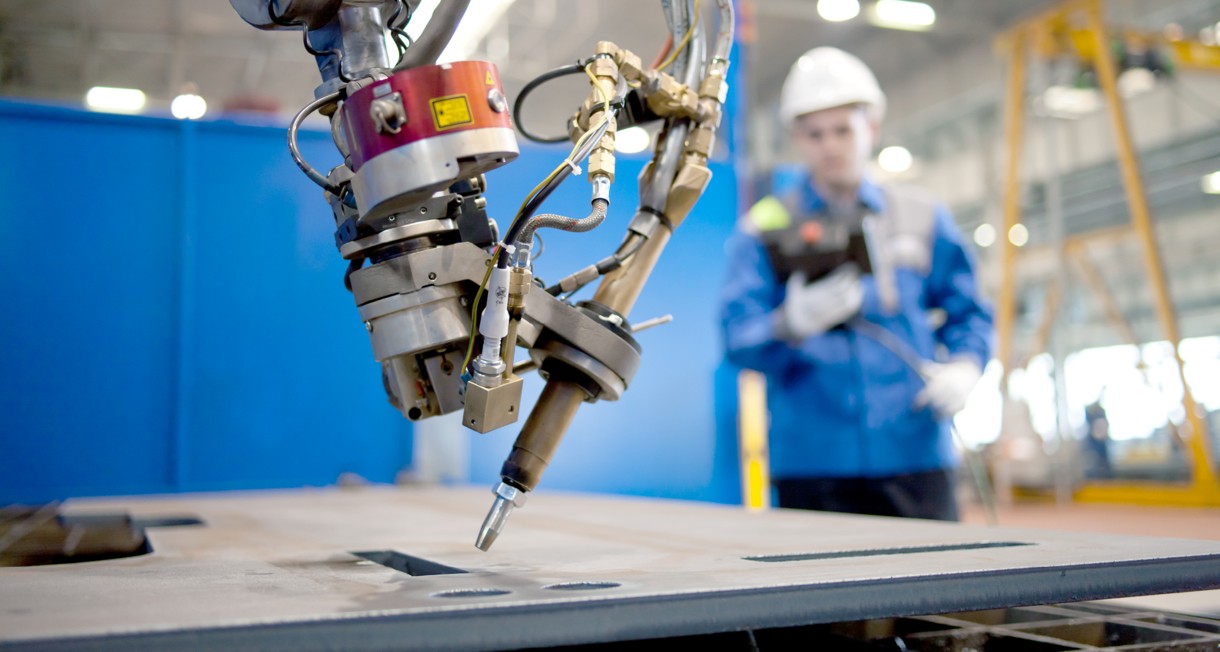

Our cut-shape facility is equipped with state-of-the-art production lines:

| Plasma | Oxyfuel | Three-torch cutting | |

| Cutting zone | 6 x 27 m | 6 x 27 m | 8,2 x 27 m |

| Thickness | 8 - 40 mm | 10 - 300 mm | 10 - 200 mm |

The different burning technologies are perfectly matched with the thickness and grade of the starting material. The expertise of our technical specialists guarantees excellent cutting quality and compliance with the narrowest tolerances. Their knowledge coupled with our modern mechanical equipment allows implementation of complex cutting configurations.

The high quality of gas-cut heavy plates is optimally supported through further processing. Each of these steps is available to our customers on a commission basis.

We offer a comprehensive service package.