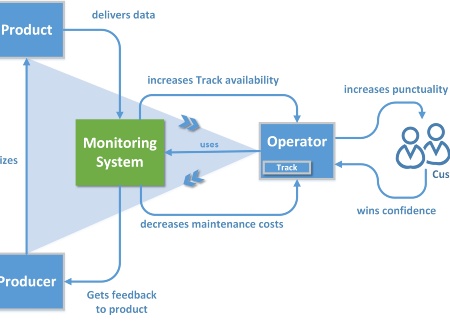

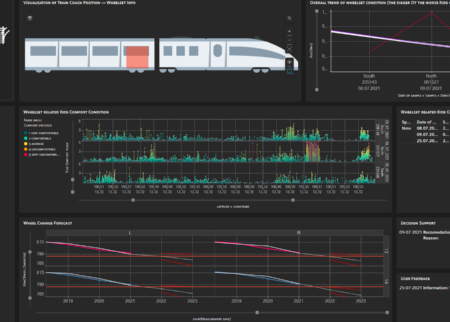

The goal of the PRM4.0 project is to create a prototype for a condition-based and predictive monitoring system for railroad infrastructure.

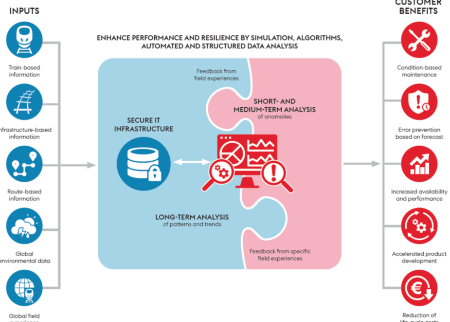

An essential core element is the fusion of track and vehicle data as well as relevant external data sources such as weather data, timetables and dispatch plans. The use of energy-autonomous sensors or virtual sensors, which are currently atypical for the railroad infrastructure or have yet to be developed, and the combination of data- and model-driven analysis methods based on real-time data from a test site will enable accurate forecasts of the short- and medium-term condition of the railroad infrastructure.

The use of machine learning algorithms as well as artificial intelligence methods should enable reliable statements on condition developments of the railroad infrastructure, which will significantly increase availability while reducing life cycle costs.