NEW TOUGHNESS REQUIREMENTS ACCORDING TO EN 10225

The availability of natural resources in areas with harsh environmental conditions is forcing structural design rules into completely new fields of interest. A drop in design temperature combined with enhanced requirements on component fracture mechanic properties are confronting steel producer with tremendous challenges.

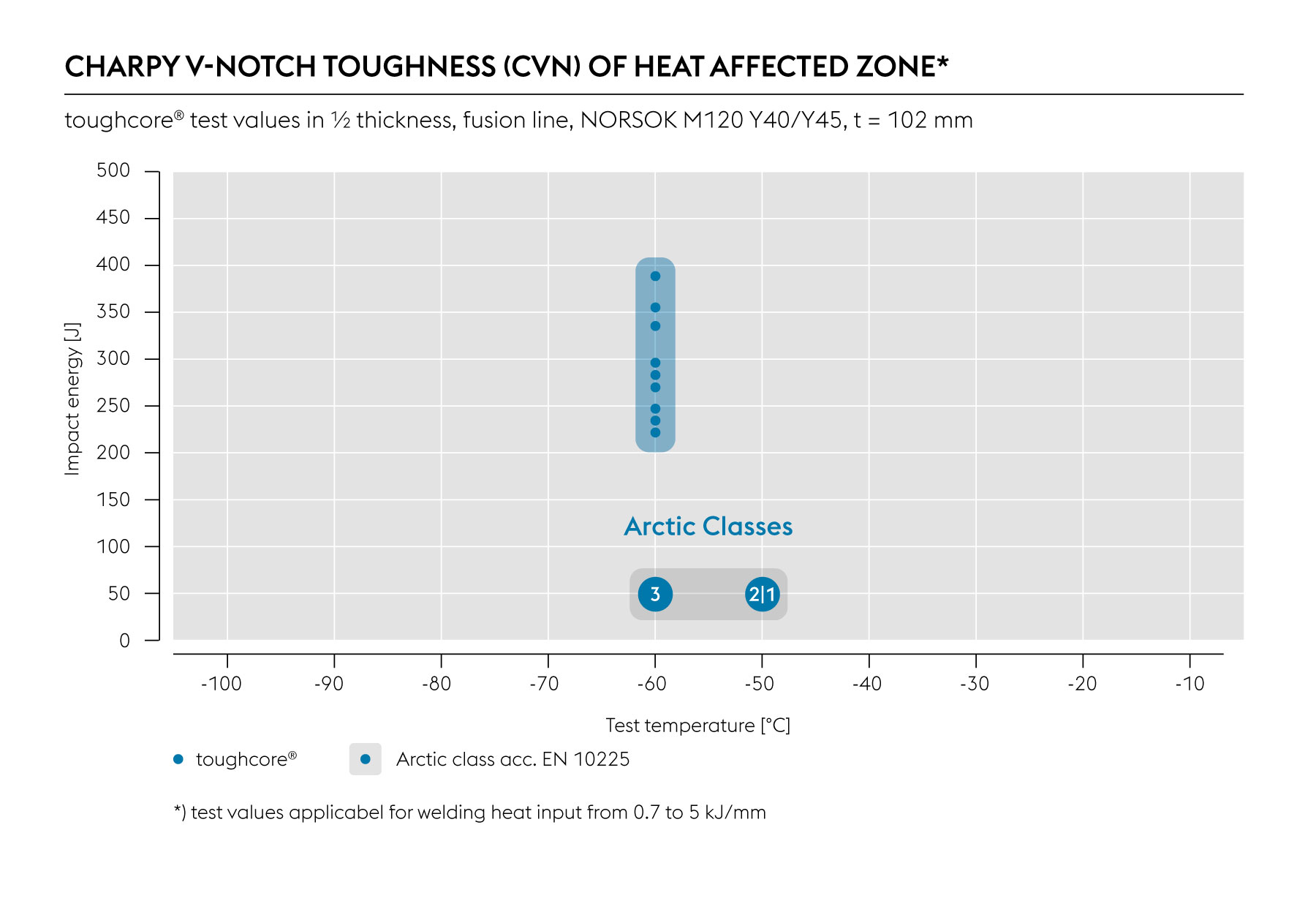

The latest draft of EN10225 (prEN10225, 2017) is covering arctic requirements within its Annex F. Depending on the actual design temperature plates shall undergo heat affected zone welding pre-qualification with acceptance criteria as described in Table 1.

| Arctic areas | Fracture mechanics test Temperature [°C] | Charpy test Temperature [°C] | Tensile test Temperature [°C]a |

| 1 | -20 | -50 | -20 |

| 2 | -30 | -60 | -30 |

| 3 | -40 | -60 | -40 |

a) if required

Putting the focus on the entire supply chain from installation, exploration, transportation to storage voestalpine Grobblech GmbH gives the answer to an upcoming market with a TMCP-based plate design satisfying this demanding new world.

toughcore® - TMCP THE NEXT GENERATION

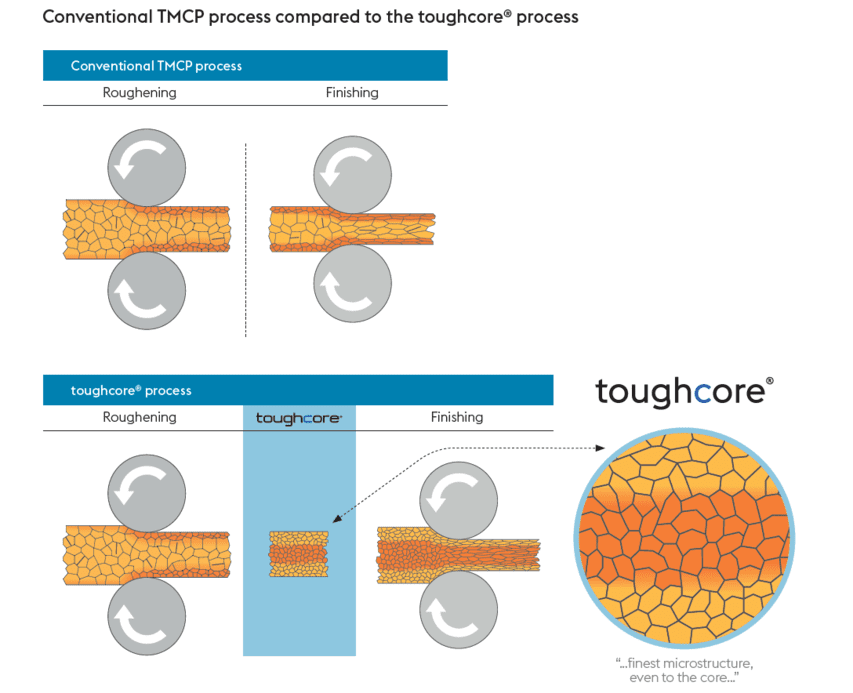

toughcore® heavy plates are characterized by their extremely high toughness even to the core as a result of their remarkably fine microstructure throughout the entire cross-section. The microstructure is refined even in half plate thickness by accelerated cooling and consecutive fast reheating during the rolling process.

Our new generation of thermomechanically rolled (TMCP) steel is manufactured in a completely new and patented process that enables unique combinations of properties with respect to thickness, strength, excellent toughness even at lowest temperatures and best weldability.

HEAT AFFECTED ZONE QUALIFICATION OF toughcore® HEAVY PLATES

Considering the requirements of prEN10225, Annex F voestalpine Grobblech GmbH successfully finished the full set of heat affected zone qualification for grade S460 constant yield in 4-inch wall thickness.

The actual test results as partially displayed hereafter are demonstrating the remarkable potential of toughcore® heavy plates in terms of outstanding toughness properties but even more in fracture mechanics at highest heat inputs.

Bilderleiste

toughcore® HEAVY PLATES FOR JOHAN CASTBERG FPSO - A TRACK RECORD

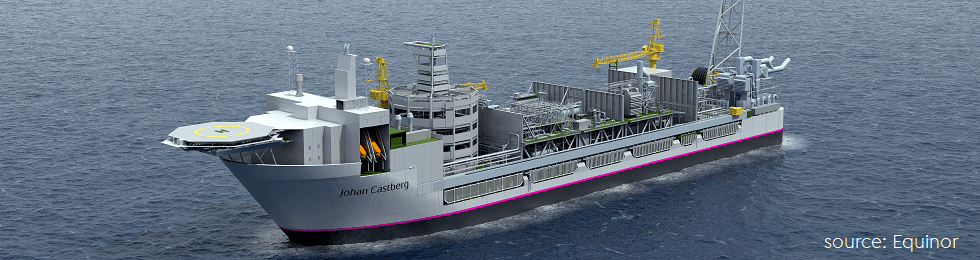

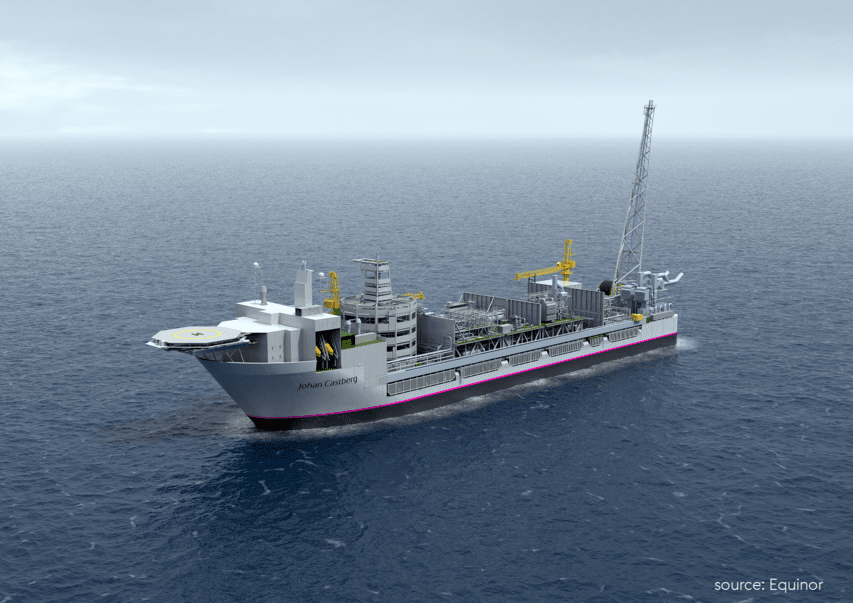

voestalpine Grobblech, as a worldwide supplier of high-quality niche products in the energy business, successfully supplied from June to Dec 2018 around 700 tons of toughcore® heavy plates in grade S420G2+M, Norsok M120 Y30/Y35 for building the Arctic Class 1 topsides of the FPSO Johan Castberg.

The Equinor operated Johan Castberg project comprises of the discoveries Skrugard, Havis and Drivis, showing an estimated volume of 400 to 650 million barrels of oil.

The oil field is situated approx. 250 kilometres north of Tromsø / Norway in the Barents Sea in blocks 7219/9 and 7220/4, 5, 7. The sea reaches water depths of around 400 meters.

The FPSO vessel is designed to receive oil & gas directly from the well, process them, and store oil until it can be offloaded onto a tanker or, transported through a pipeline onshore. FPSOs are preferred in frontier offshore regions as they are easy to install, and do not require a local pipeline infrastructure to export oil.

Additionally to the drilling and production facilities on board of the Johan Castberg FPSO, living quarters for around 160 people will be installed on deck to accommodate the crew.

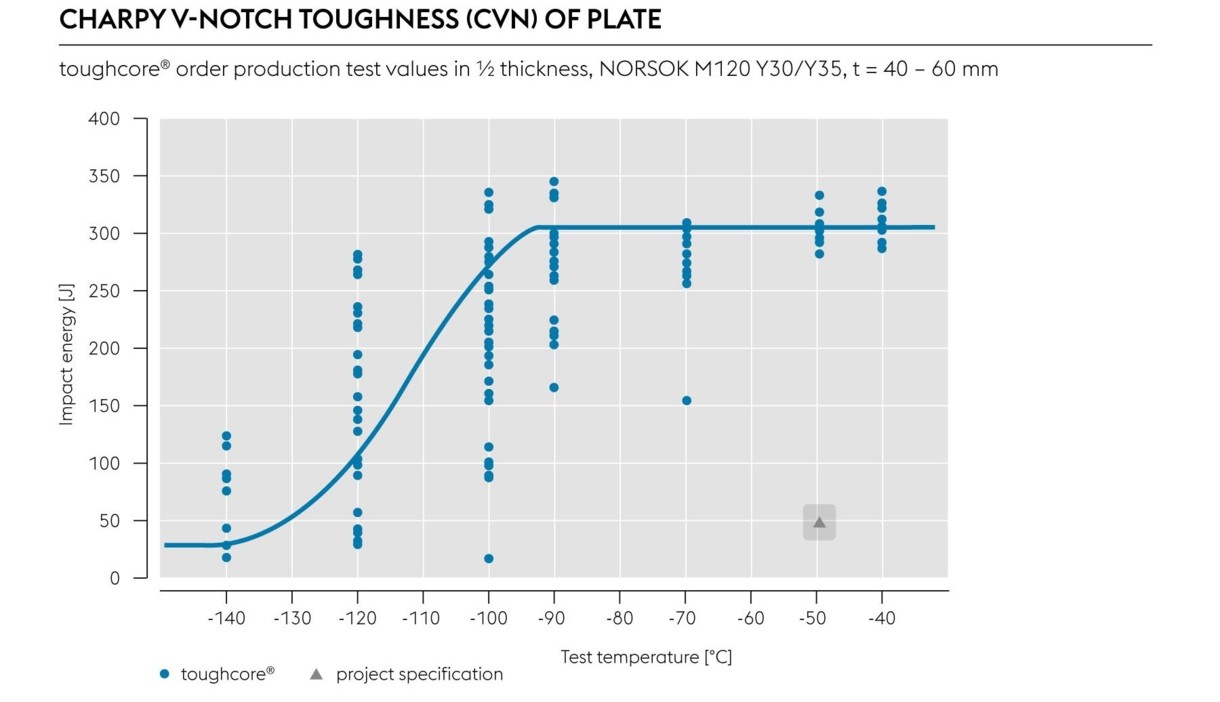

TEST RESULTS OF toughcore® PLATES DELIVERED FOR JOHAN CASTBERG

toughcore® HEAVY PLATES FOR LOW TEMPERATURE LINEPIPE APPLICATION

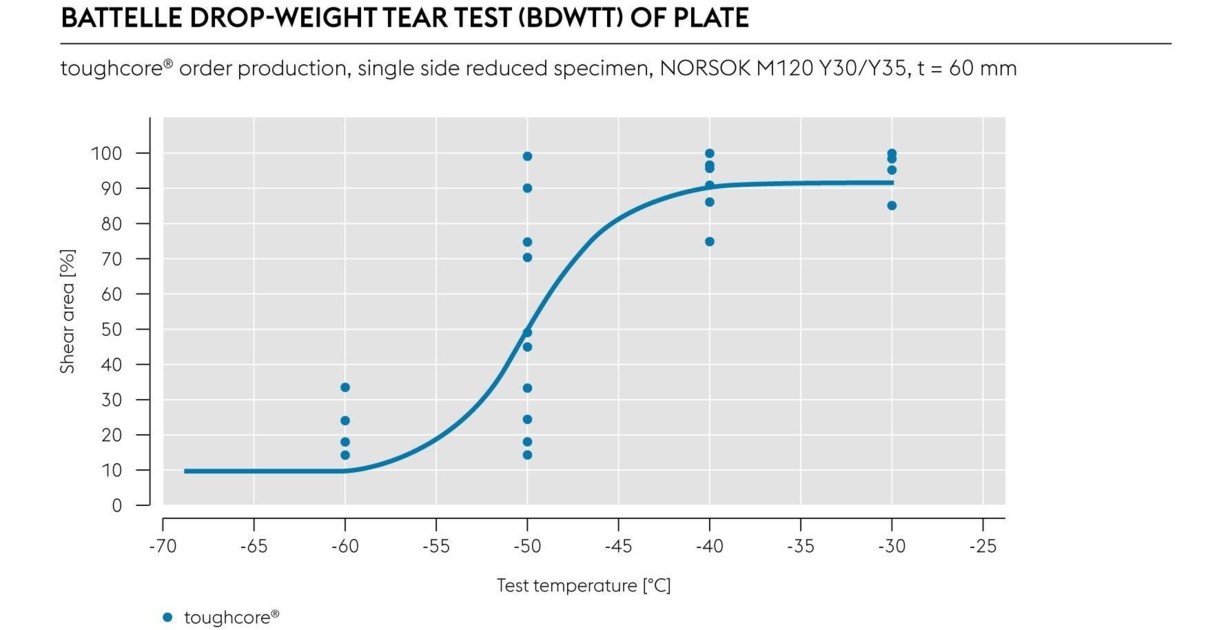

Bearing in mind that the Johan Castberg plate design was not optimized to stand low temperature drop-weight tear test properties a transition temperature of -50 °C in wall thickness 60 mm is displaying another potential of voestalpine toughcore® heavy plates.

Utilizing this potential in linepipe industry, it is now possible to substitute buckle arrestors made out of forgings by thick walled heavy plates made out of toughcore®.

toughcore® - THE FULL POTENTIAL

The superb material properties of toughcore® and the finest microstructure throughout the entire cross section guarantee highest safety levels during operation of offshore platforms and jackets or other offshore constructions even at very low temperatures.

The design of these components can be optimized using high-strength toughcore® with sufficient wall thickness and excellent toughness. This allows higher loads and increased safety levels.

Using the unique toughcore® process for linepipe application, high-strength plates with significant higher wall thickness can be produced as compared to conventional material. For instance buckle arrestors, crack arrestors, connectors or casings made of toughcore® with an increased wall thickness and highest toughness – even at very low temperature – increase the operational safety of a pipeline.

In the interest of storage and transportation of liquefied gas, toughcore® can be an answer to fulfill toughness requirements of Nickel steel with a significant lower Nickel content while achieving the same mechanical and technological requirements. At the same time, material cost will be reduced.

Our new generation of thermomechanically rolled (TMCP) steel is manufactured in a completely new and patented process that enables unique combinations of properties with respect to thickness, strength, excellent toughness and best weldability.