Structures and machines for arctic regions

toughcore® provides finest microstructure throughout the entire cross-section. Therefore extreme toughness properties can be realized for thick plates, even to the core of the material and at very low temperatures.

To avoid the brittle fracture of a component, the respective part must be operated at a minimum design temperature which is above the transition temperature. Using toughcore® the transition temperature will be lowered significantly. Cranes, trucks and mining equipment can be operated at, structures, buildings and bridges can be designed for lower temperatures e.g. in arctic regions, Alaska or Siberia without taking the risk of a brittle fracture.

Best weldability

Using toughcore® we are able to produce high-strength TMCP plates with higher thickness and excellent toughness, which is not producible with conventional thermomechanical rolling processes.

Applications for machinery industry which currently required QT steel can now be substituted by toughcore® TMCP steel.

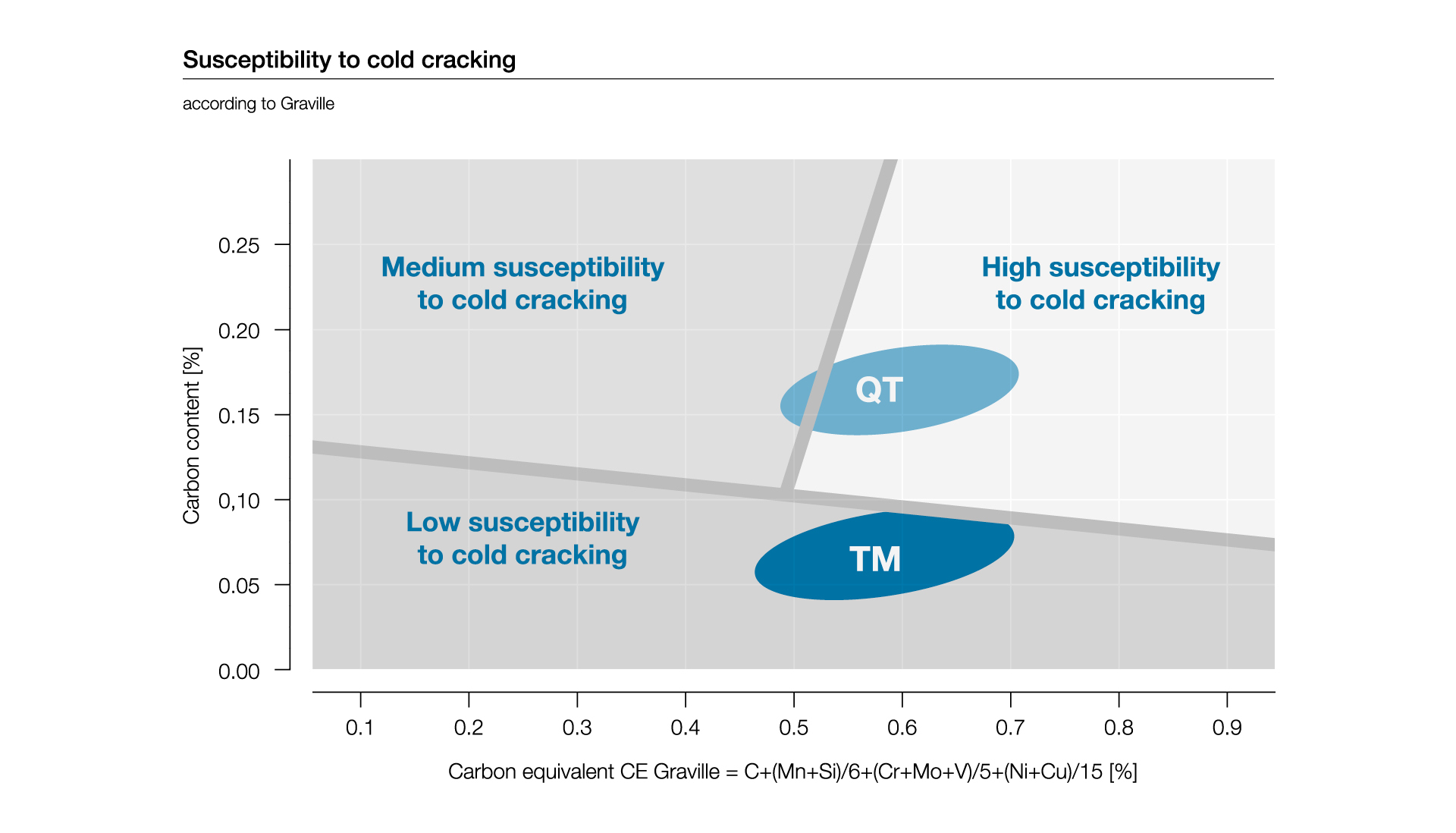

Compared to QT steels, TMCP steels show a lower sensitivity of cold cracking due to the low carbon content. You will benefit from a lower sensitivity of cold cracking due to the low carbon content and better weldability of TMCP steel compared to QT steel.

Available dimensions

- We deliver high-strength TMCP plates with excellent toughness for applications where up to now only QT steel was able to fulfill your requirements

- alform plate S355 / S420 / S460 ML toughcore up to a thickness of 140 mm with outstanding toughness properties, even for arctic application and / or to increase the safety level