BV, DNV and RINA approve HB Hunte's revolutionary tank design made of voestalpine Grobblech's F550 TMCP toughcore, opening the door for safer LCO2 transport.

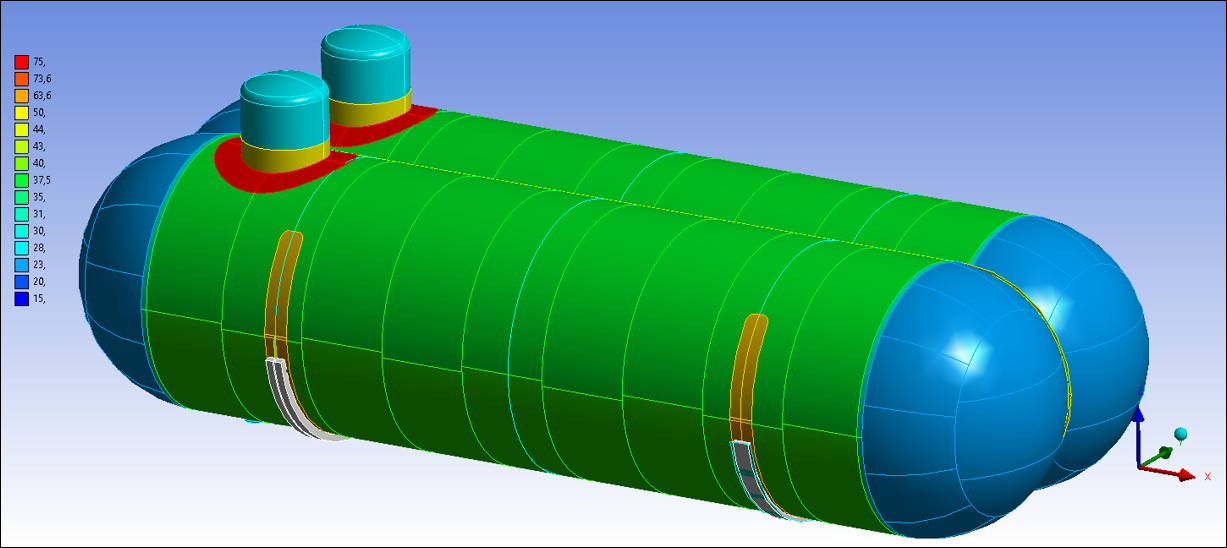

Liquid Carbon Dioxide (LCO2) cargo handling brings new challenges to tank designers and manufacturers due to its particular physical properties. One of the challenges for example is how to balance pressure and deep temperatures to be able to liquify Carbon Dioxide and at the same time prevent dry ice formation in the tank.

In order to be able to surpass these challenges the optimal storage tank material is imperative to assure safe and reliable LCO2 transportation, especially when transporting it by ship where dynamic loads are part of any sea transport.

In order to tackle this challenge, HB Hunte Engineering teamed up with voestalpine Grobblech GmbH to define what the perfect material design wouUtilising the outstanding material properties of F550 TMCP toughcore, HB Hunte, together with voestalpine, is able to offer an economic solution, higher production efficiency and best safety approach for very challenging cargo, like LCO2.ld look like.

Several requirements were set, it needed high strength, the ability to withstand temperatures down to -80°C whilst providing excellent Charpy V-notch test results, and CTOD results above 0.2mm at temperatures down to -40°C.

Therefore, the voestalpine Grobblech material specialists decided to combine its toughcore® technology with the well-known F550. In doing so, the F550 TMCP toughcore was developed, providing the optimal solution for marine LCO2 transportation.

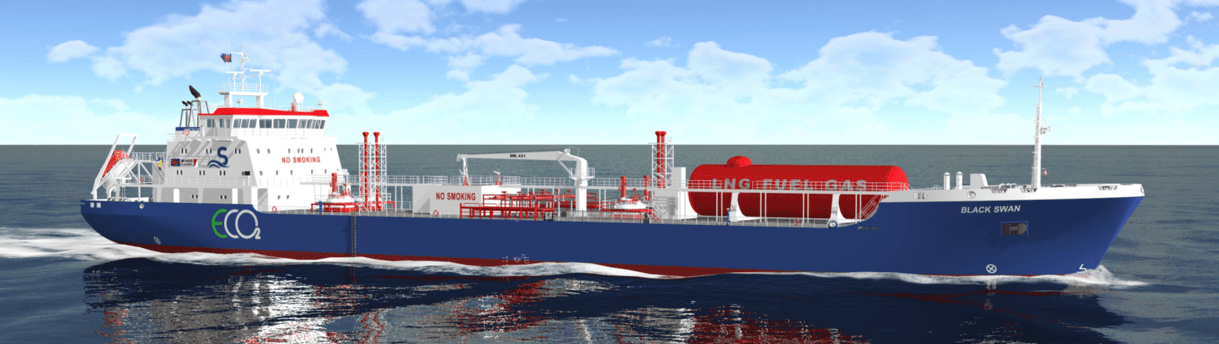

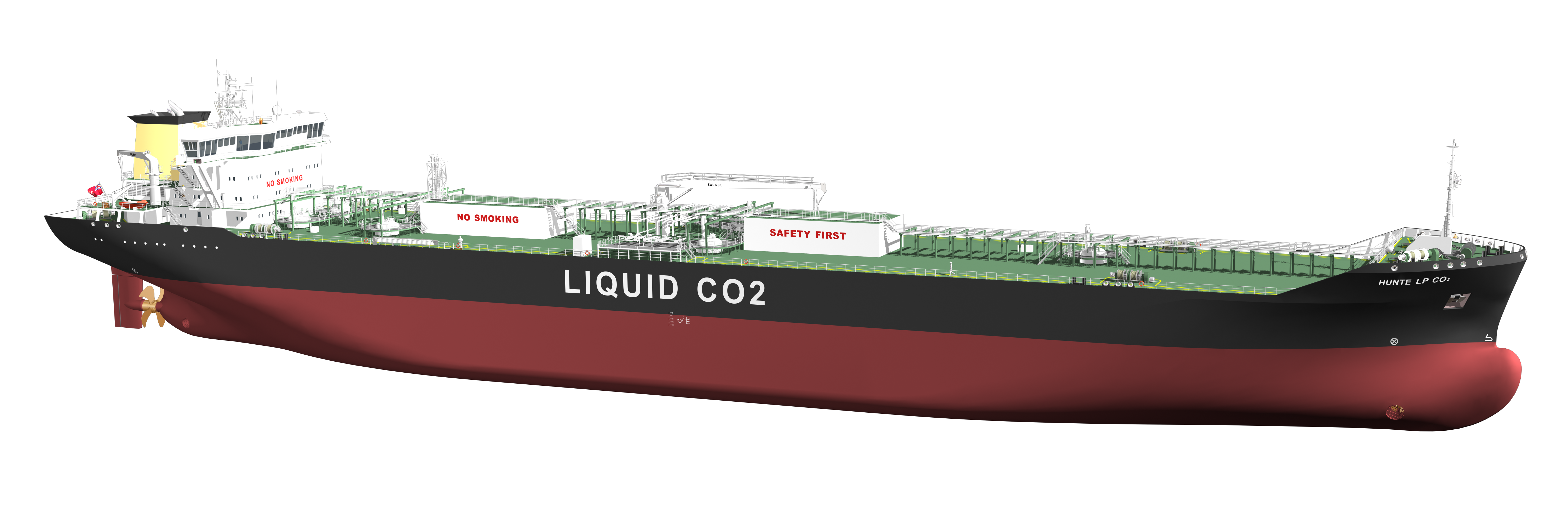

F550 TMCP toughcore carbon steel is now allowing HB Hunte Engineering to design LCO2 cargo ships with the most efficient and safe IMO Type C pressure tanks.

HB Hunte Engineering has obtained several AiPs for its innovative IMO Type C tank designs and efficient cargo vessels using this game-changing material. The class societies BV and RINA where the first to release AiPs for these cargo vessels with different cargo capacities. DNV followed recently by awarding an AiP for the design of a LCO2 tank using F550 TMCP toughcore material accompanied by a second AiP for the dedicated vessel.

The actual designs at medium pressure and temperatures down to -40°C cover capacities up to 7,000m³ for a single tank, whereas the overall ship's cargo capacity ranges up to 36,000m³ and even larger projects have just started.

Providing pressure vessels in cylindrical, Bi-lobe or Multi-lobe shapes, HB Hunte offers an optimised ship-tank solution to meet the most efficient cargo hold to capacity ratio.

Utilising the outstanding material properties of F550 TMCP toughcore, HB Hunte, together with voestalpine, is able to offer an economic solution, higher production efficiency and best safety approach for very challenging cargo, like LCO2.