Dates

Request now!

Level:

Basic

Contact

- WS Academy partner of Railway Systems

- Heidemarie Sieder

- + 43 664 8561420

- Send message

Course content

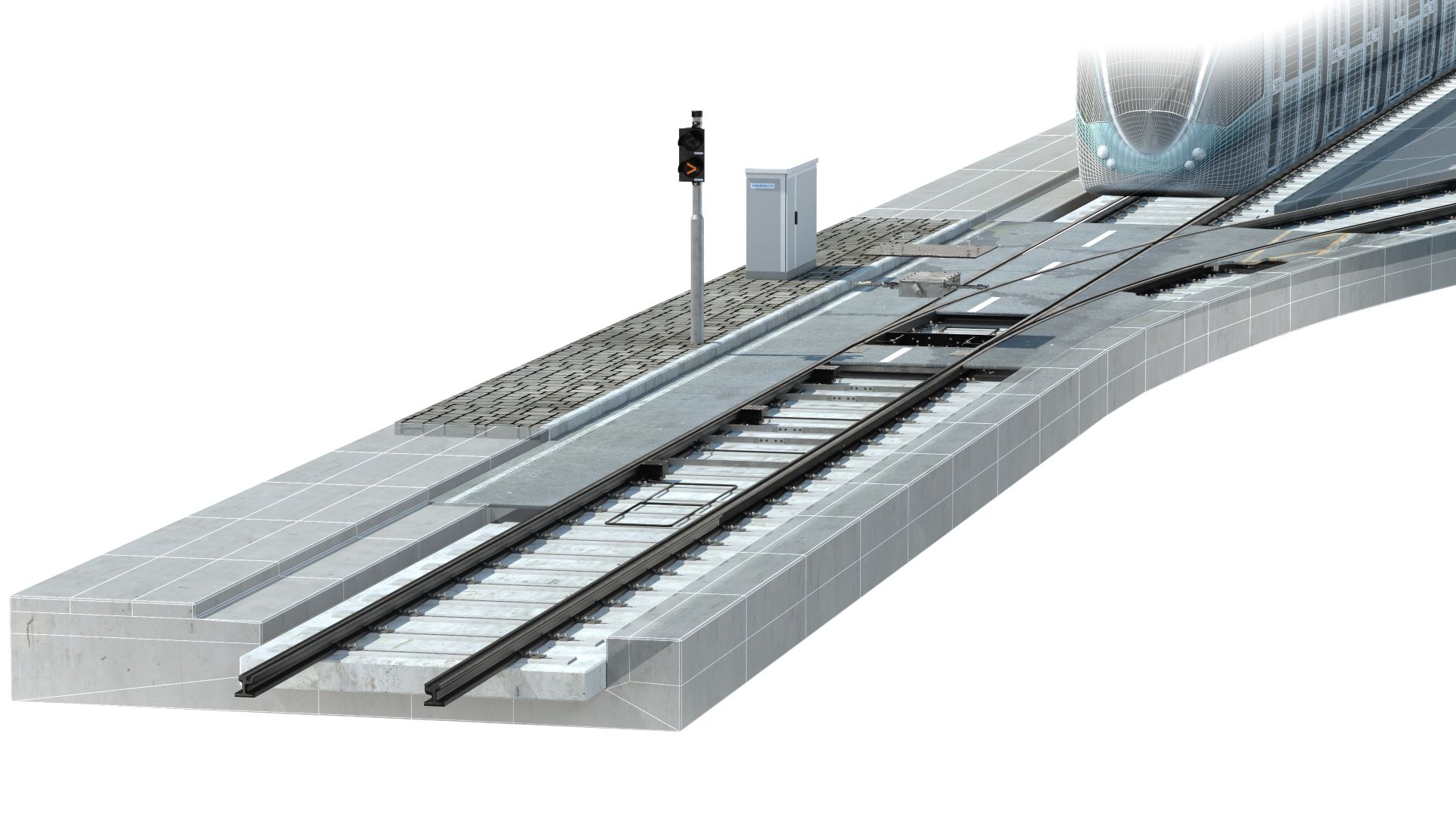

- Definition turnout

- Turnout types and systems (standardized terms and designations)

- Turnout nomenclature (geometric picture, turnout radius, final inclination, components)

- Rails (profiles and materials)

- Dependency on turnout geometry and permissible speed

- Basic knowledge of guidance, impact on component design (tongue device, crossing and check rail)

- Tongue devices (types, structure and mode of operation)

- Crossing area (crossing and check rail, types, flat and deep groove)

- Climbing turnouts - why and how does it work

- Positioning systems and their basic requirements or tasks

- Relationships between speed of travel and positioning or locking device

- Superstructures, stray current insulation, fastening systems

- Summary of the special features "turnout system" with an impact on planning, maintenance and technology aspects in urban transport

- Rails - materials, wear behavior, welding suitability

- Dependency on turnout geometry and permissible speed

- Calculation of lateral acceleration and its permissible speed-related values

- Track guidance effect on component design (tongue device, crossing, check rail and track arches), optimization options and limits of component design; Low-floor vehicle technology

- Tongue devices: designs, choice of materials, special designs

- Crossing area (crossing and check rails, types, flat and deep groove issues, special solutions, operational experience, special features for maintenance, movable crossing)

- Climbing turnouts - component design, standard turnouts, areas of application, positioning system and fastening

- Positioning systems and their basic requirements or tasks - effect on turnout construction, module systems; security technology

- Superstructures, stray current insulation, fastening systems (closer examination of the requirements for stray current and elastic mounting)

- Assembly, shipping, transport and logistics - special features depending on the turnout systems and laying system