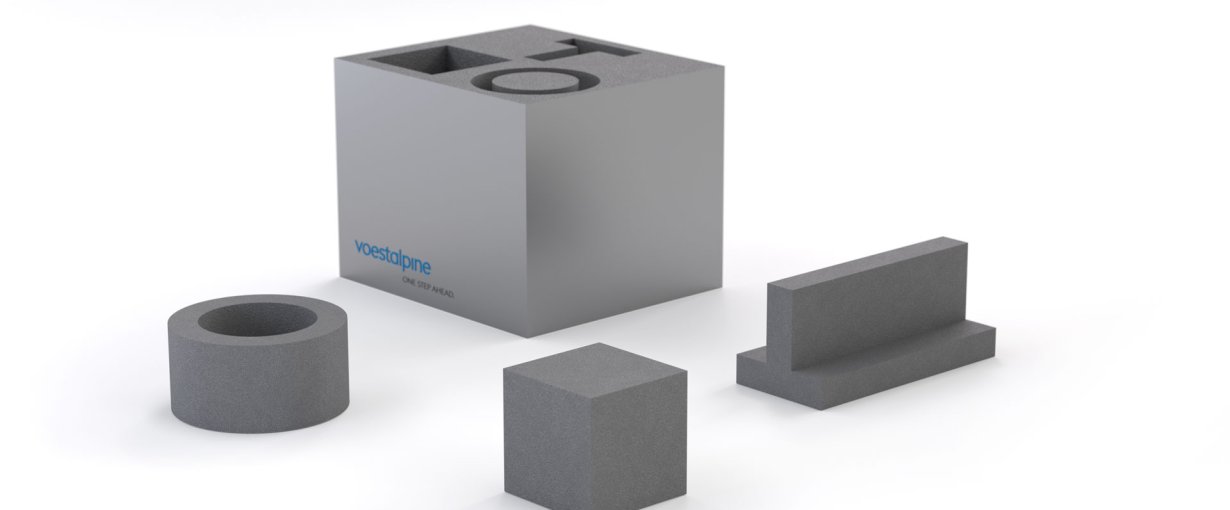

voestalpine Venting Structures

designed for pure performance

Using additive manufacturing, venting structures with a microscopic porosity can be produced that allow a targeted release of compressed air and ensure that the mold remains air free during injection. These structures help to avoid defects caused by the diesel effect, which is a well-known industrial problem. Our geometry independent venting structures provide application-specific venting performance and allow an easy and customized integration into the mold. Using our corrosion-resistant premium materials by BÖHLER /Uddeholm, the structures ensure high part quality throughout the mold lifetime.

The high material and functional quality of our Engineered Products leads to improved overall equipment effectiveness (OEE). This is achieved through a reduction in scrap rates caused by defects such as burn marks and short shots, and a lowering of required injection pressure, which can contribute to energy savings.