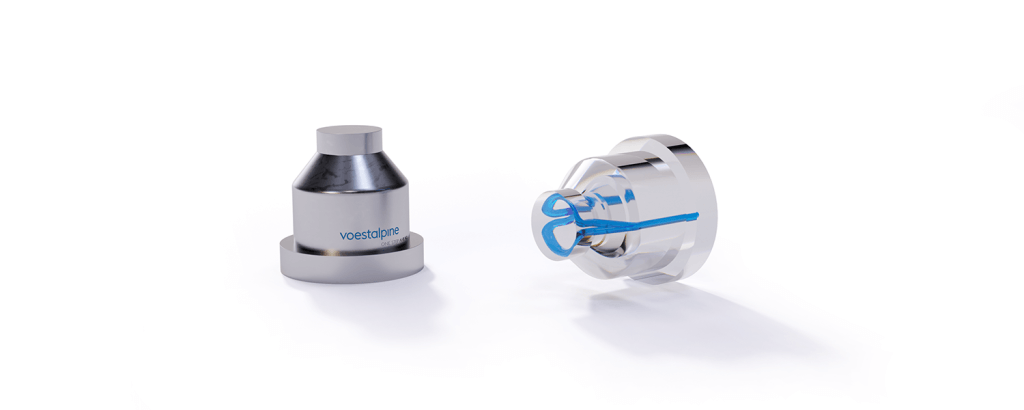

voestalpine Inserts for Food Container Lids

designed for pure performance

Our Inserts for Food Container lids have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

With more homogeneous temperature distribution, our inserts enable improved productivity and can reduce the overall cycle time by up to 15% compared to conventionally manufactured products.

Many producers of food container lids have tested our AM solutions and confirmed the increased profitability by using our corrosion-resistant Inserts for Food Container Lids.