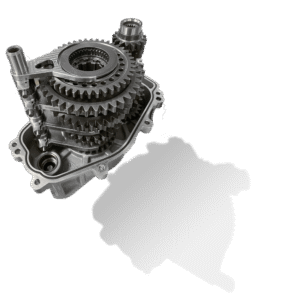

Gears

Racing gearbox materials fail due to a combination of mechanical overload, wear, fatigue and impact events. Despite advanced engineering, the brutal conditions of racing push every component to its limit. Race gearboxes also need to remain lightweight while meeting stringent packaging constraints to retain a competitive advantage. Selection of the right materials can certainly help solve many problems however, regular maintenance, precise engineering, and good driving technique are also key to maintaining reliability.

Steels used to manufacture components in racing gearboxes typically fall into the following categories:

| Category | Typical Applications |

| Case carburising steels | Gears |

| Through-hardened high-strength & nitriding grades | Dog rings, shafts |

| Pre-hardened medium-strength steels | Less stresses components e.g., selector forks, barrels, spacers |

Most Common Causes of Material Related Failure

1. Overloading and Torque Spikes

- Racing applications require the driveline to transmit very high torque and power, overload conditions which exceed the typical design limits of the gearbox can be a frequent occurrence.

- Sudden throttle inputs, aggressive downshifts, and wheelspin can create torque spikes that damage gears and shafts.

High tensile strength (≥1300 MPa)

High yield strength (≥1000 MPa)

High fracture toughness, especially in the core

Case Carburising grades

BÖHLER V135 & E108 deliver exactly these properties, maintaining a high strength but tough core beneath a hard case. This means that gear teeth can withstand sudden overloads.

Through hardened high-strength steels BÖHLER W460, W360 & V132 offer a myriad of possibilities to increase hardness and strength offering designers a wide array of possibilities to increase a component’s performance and reduce failures.

2. Wear of Dog Rings and Engagement Mechanisms

- These components wear quickly, especially under high loads and harsh shifting.

- Most racing gearboxes use a dog selection method (instead of synchros) for reduced shift times.

High hardness >40HRC

Harder case depths (60–64 HRC) with 0.8–1.5 mm effective depth

High / Medium strength through hardened steels

High-performance steels offer a myriad of possibilities to increase hardness, compressive strength & wear resistance in the most arduous applications. If required, surface hardness can be further increased through nitriding.

3. Fatigue and Material Limits

- Even high-end materials reach their limits in high-stressed motorsport environments.

- Repeated stress cycles cause fatigue in gears, shafts, and bearings, eventually leading to cracks or catastrophic failure.

Increased cleanliness: most fatigue failures begin at internal inclusions.

Case carburising and through hardening steels

Böhler high-performance steels are often remelted using:

- VAR (Vacuum Arc Remelting)

- PESR (Protective Gas Electro Slag Remelting)

These manufacturing techniques significantly improve the cleanliness of steels including BÖHLER V135, M121 and E108, by eliminating oxide & sulphide inclusions which dramatically decrease the fatigue life of components.

4. Impact Loads (Crashes, Curbs, etc.

- Sudden shocks from curbs, crashes, or excessive drivetrain lash can introduce irregular forces that damage the gearbox housing or internals

High fracture toughness, especially in the core

Case Carburising grades

High-toughness steels like BÖHLER M121 have fracture toughness ratings that allow them to withstand shock without cracking, especially at lower temperatures or high strain rates.

High / Medium strength through hardened steels Steels such as BÖHLER K600, M238 & V358 are designed to be tough to withstand impact loading. If required, surface hardness can be increased through nitriding