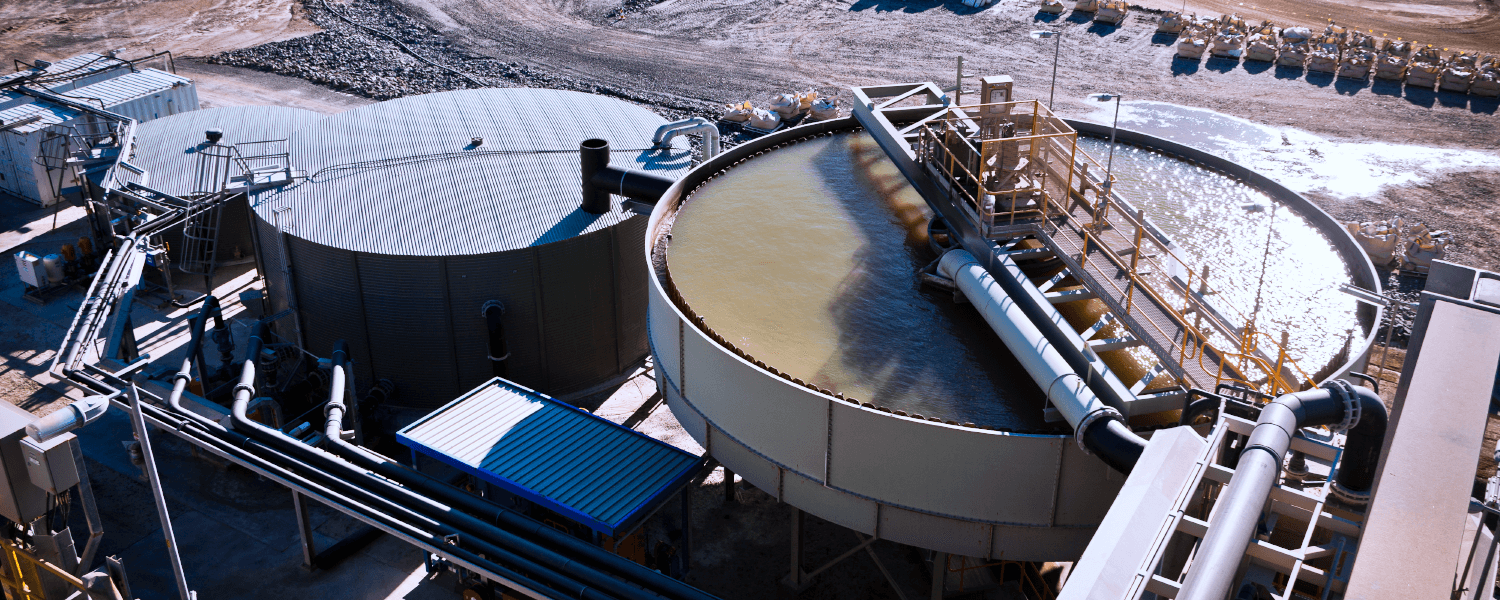

Pumping Applications

High performance materials for pumping and filtration

voestalpine tool steels are highly suitable for pumping components due to their corrosion and abrasive wear resistance. These properties ensure that the pumping components can withstand operation in abrasive slurry pumping applications, maintaining their structural integrity and performance over longer periods of time.

Performance where it counts

Our tool steels have a proven track record in the mining industry and are suitable for many pumping applications including:

- Valve Body

- Valve Seats

- Support Flanges

- Shaft Sleeves & Spacers

This is only a small selection of the applications where voestalpine material grades can be a game changer for your pumping applications. If you have an idea for a project or there an existing problem needing a solution, contact you local voestalpine High Performance Metals technical team using the form below.

voestalpine Premium Materials

The excellent combination of toughness and wear resistance offered by tool steels makes them an ideal replacement for traditional high tensile or case hardened materials in a range of applications where corrosion and erosion are major issues.

The table below shows a selection of the wear resistant grades available.

| BÖHLER | ASSAB / Uddeholm | Villares | W.N.R (EN/SEL) | MAX. (HRC/HB/HV) |

| M333 ISOPLAST | Mirrax ESR | – | – | 50 |

| M310 ISOPLAST | Stavax ESR | VP420IM | 1.2083 | 52 |

| M303 HH | Mirrax 40 | V2316MOD | 1.2316 | 40 |

| M315 | RoyAlloy | – | PATENT | 310 HB |

| M340 ISOPLAST | – | – | PATENT | 55 |

| M368 MICROCLEAN | – | – | PATENT | 56 |

| M390 MICROCLEAN | Elmax SuperClean | – | PATENT | 60 |

| N690 | – | – | 1.4528 | 61 |

| – | Corrax | V630IM | – | 50 |

| – | Tyrax ESR | – | PATENT | 58 |

| – | Vanax SuperClean | – | PATENT | 60 |