voestalpine Flow Filter V & X

designed for pure performance

Nozzle filters are used to prevent contamination from the plastic melt causing blockages or interruptions to the injection process. These contaminates can cause damage to hot runner systems, resulting in extended downtime and increased maintenance costs.

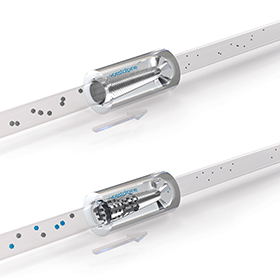

The design of the voestalpine Flow Filter V & X capitalizes on the unique capabilities of additive manufacturing to create a high-density solid mesh filter. Flow Filter X combines filtration and mixing properties, thereby reducing masterbatch consumption. Flow Filter V provides an extremely low pressure drop (up to 65% compared to comb filter). These filters provide improved performance over traditional injection molding nozzle filters and are available in both standard sizes and tailored dimensions.

The use of voestalpine Flow Filters increases part quality, reduces scrap rate, significantly reduces shear stresses, and reduces masterbatch consumption. The filters also exhibit high wear- and corrosion resistance as a result of their premium material composition.