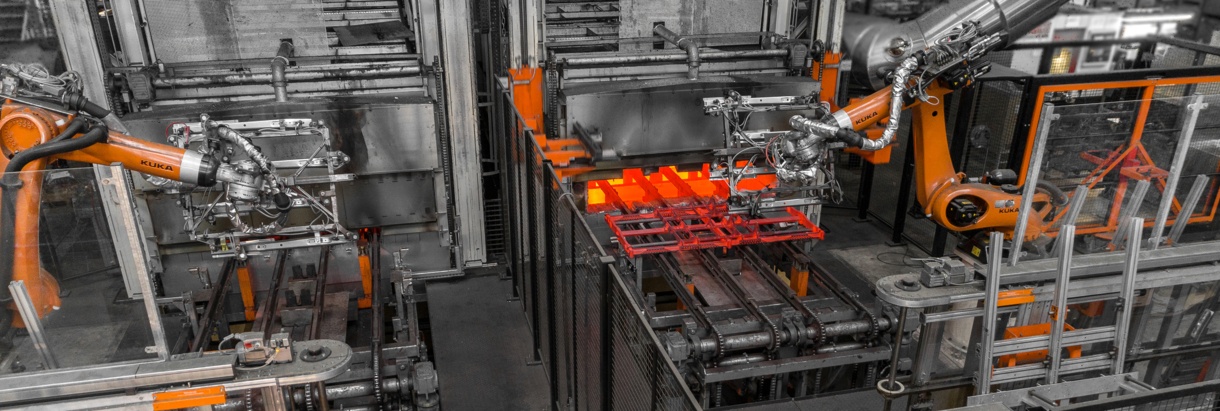

Production location for cold stamping and hot forming

Opened in 2015, voestalpine Automotive Components Shenyang Co. Ltd. produces complex, ready-to-install assemblies as well as stamped and formed parts. The plant specializes in the hot forming of crash protection parts, using the innovative phs-ultraform® technology. With the help of it’s sophisticated production technologies, the Shenyang plant is able to realize challenging component geometries with the necessary degree of hardness as well as lightweight construction properties and corrosion resistance. With around 170 employees, the Shenyang location is technology partner for notable European and Asian car manufacturers.

Competences

We use an indirect process known as our phs-ultraform® process to manufacture press-hardened components in a new dimension of design freedom, dimensional accuracy and process reliability. You can find more information about the phs-ultraform manufacturing process here.

- 630 t presses

- 2 phs lines

- 2 body construction cells

- 2 large and small assembly lines