Competence Center for Hot Forming & Assemblies

voestalpine Automotive Components Schwäbisch Gmünd GmbH & Co. KG specializes in manufacturing press parts for the automotive industry. Around 700 employees produce exposed panels and tools. A defining feature of our location is its technical expertise, thanks to long-time partnerships with renowned automotive customers.

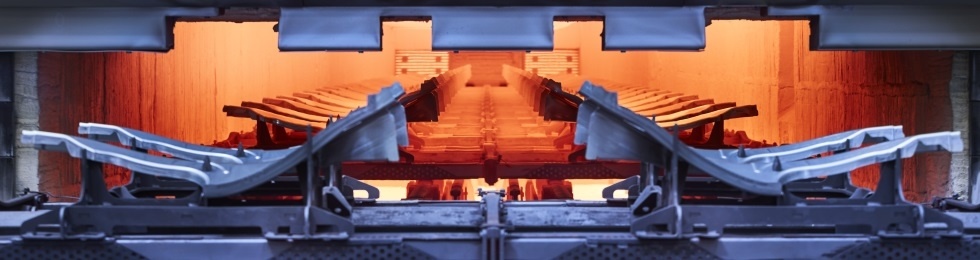

Innovative phs technology enables the production of press-hardened high-strength and corrosion-resistant body parts made of galvanized steel strip. This results in particularly lightweight, strong and, as a result, safe components for the automotive industry which are used as side members, side walls or door elements, for example. In addition, our plant is considered the competence center for hot forming within the voestalpine group.

Further production and development centres for the hot forming business segment are located in Germany, the US and China.

Tel. +49/7171/972-0

Tel. +49/7171/972-0

Plant Management

Tel. +49/7171/972-0