Innovative stack production for greater economy and sustainability

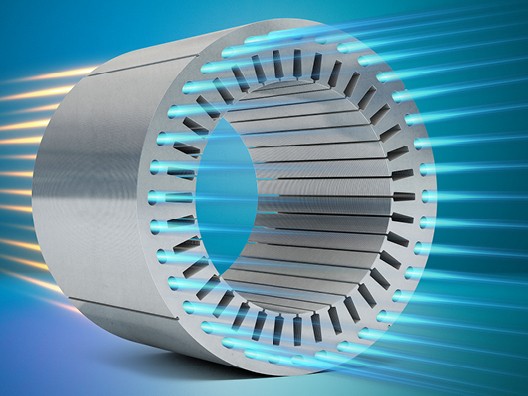

Revolutionary difference: The novel process control of toptyte® PROCESS with pulsating compaction and individual hardening enables the production of media-tight stacks that herald a new era in terms of tightness, efficiency and sustainability. This means that even more powerful and efficient motors with integrated cooling can be economically produced in series.

The benefits of toptyte®PROCESS at a glance

Laminations coated with Backlack are pressed together under pulsating pressure and harden individually. The result is 100% media-tight rotor and stator stacks with integrated cooling. The total cost of ownership in production is significantly reduced for more powerful and efficient motors.

How the pulsating process works

The novel approach of toptyte®PROCESS is based on the principle of pulsating compression: The electrical steel laminations are pressed together with short pressure pulses and increasing temperature until total tightness is achieved. This is verified inline before the material hardens, thus minimizing waste. Any questions? We will be happy to help!

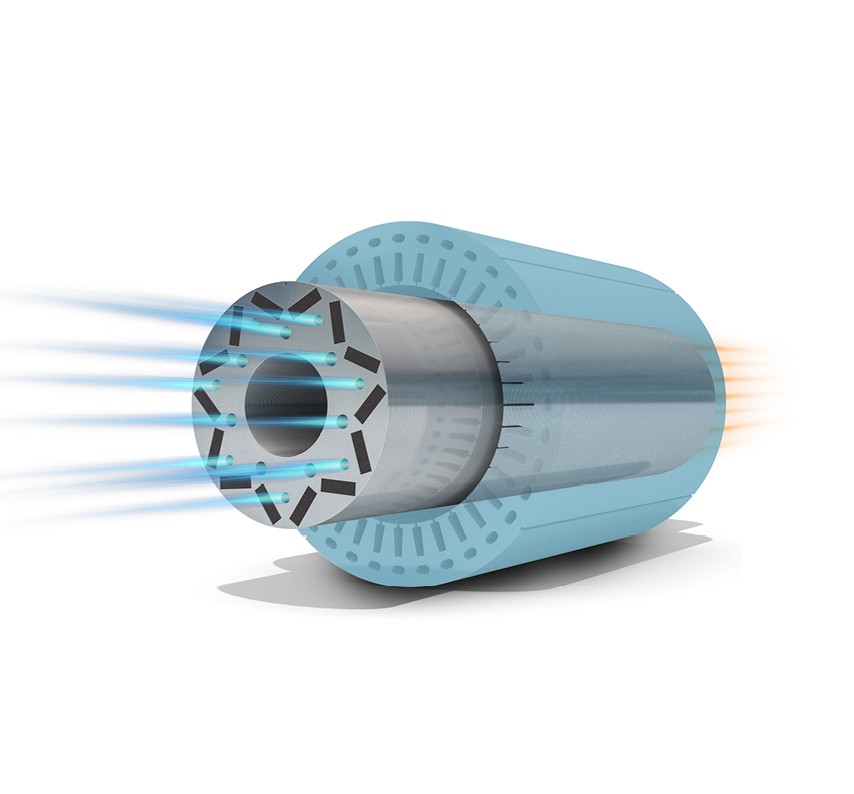

The groundbreaking solution for rotor cooling

In contrast with conventional technologies in which only the rotor shaft is cooled, direct cooling in the rotor stack ensures a higher degree of efficiency. The new production process enables electrical steel stacks with media-tight cooling channels for decisive advantages.

More powerful motors

Increased impact density and efficiency

More sustainable manufacturing

Dysprosium, a rare-earth metal, required in smaller amounts based on lower operating temperatures

More economical approach

Reduced manufacturing and material costs

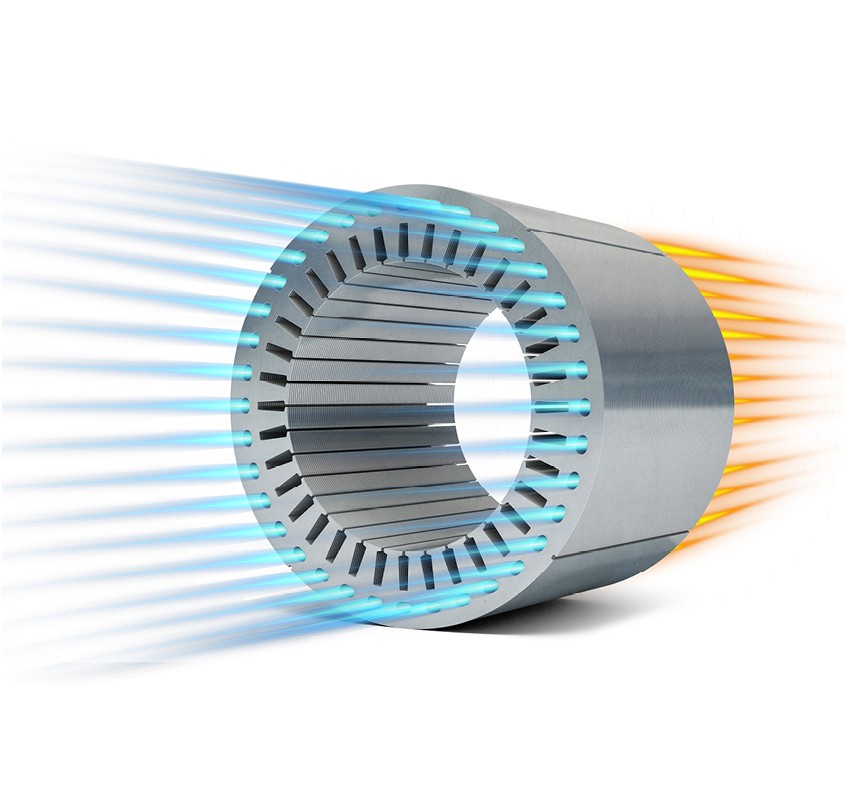

Next-generation corrosion protection in stator stacks

The alternative to conventional water jacket cooling: Cooling is directly integrated thanks to media-tight bonding. This design enables motor designs that set new standards in efficiency and compactness.

Optimized thermal management

Lower electric motor operating temperatures down to 40 °C for higher continuous torque

Significant potential savings

Lower manufacturing and overall costs

More sustainable motors

Reduced carbon emissions and increased ranges

Passed the test!

Proof of concept: Two versions of an electric motor were compared on a testing stand at the Center of Mechatronics of the Johannes Kepler University in Linz. One was equipped with conventional cooling and one with integrated cooling in a 100% media-tight stator stack. At full throttle, the temperature of the winding head was almost 150 °C in the conventional motor, while it was just under 110 °C in the motor with integrated cooling (lower by 40 °C).

Learn more about the benefits of toptyte®PROCESS!

Each of the process steps and processes are patented by voestalpine. The process is made available to manufacturers based on a license model. Would you like to know more about the process, prototype production or the economic impact? Not a problem! We will be happy to assist you.