Automotive

Driving Performance with Precision Steel

For decades, we have been a trusted partner to the automotive industry, combining unmatched metallurgical expertise with world-class service. As the global market leader in tool steels, special materials, valve steels, and powder-metallurgically produced high-end steels, we go beyond supplying materials, we provide solutions that drive innovation, improve efficiency, and enhance performance.

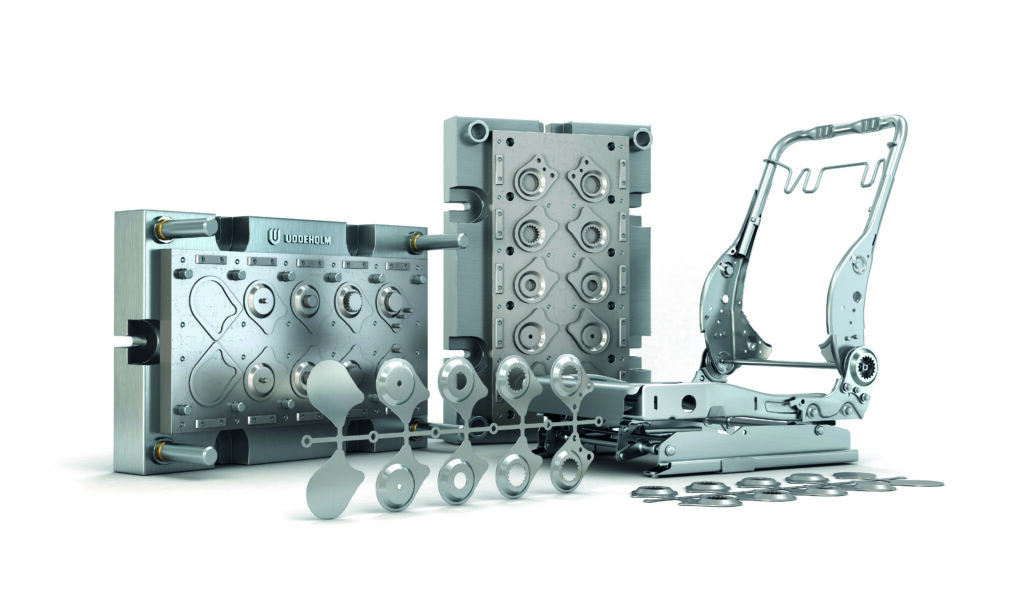

Our globally unique distribution network ensures customers receive the right steel, at the right time, anywhere in the world. We deliver complete product and service packages, including technical consultation, process optimization, and steel grades engineered to withstand the intense demands of automotive manufacturing. Whether for tool manufacturers, OEMs, or tier suppliers, our products support a wide range of processes such as die casting, injection moulding, extrusion, stamping, and precision cutting; all critical in achieving the highest production efficiency and component quality.

Steel You Can Trust – From Concept to Component

Automotive manufacturing pushes materials to their limits. Our steels are developed to excel:

- Under High Temperatures

- Intense Mechanical Loads

- Corrosive Environments

This ensures:

- Longer Tool Life

- Fewer Production Stoppages

- Consistently High-Quality Outputs

Designed to Perform – Applications Include

- Valve steels engineered to perform in internal combustion engines, maintaining structural integrity under extreme heat and pressure

- Drop-forged suspension components for commercial vehicles, offering high tensile strength, impact resistance, and safety-critical reliability

- High-speed steels for fuel injector needles, delivering exceptional hardness, dimensional stability, and wear resistance in precision fuel delivery systems

- Tool steels for moulds and dies, capable of producing complex geometries with outstanding repeatability and reduced maintenance downtime

By investing in our steel solutions, manufacturers achieve lower total cost of ownership through reduced tool replacement frequency, improved process stability, and higher production throughput.

voestalpine High Performance Metals offer a extensive selection of tools steels from our BÖHLER and UDDEHOLM brands. With over 250 different grades available to choose from – each offering unique chemical compositions and material properties – we have material grades designed to perform in the most demanding environments.

Passenger Vehicle OEMs (< 3.5t)

We are the foundation of passenger vehicle manufacturing. Leading OEMs worldwide rely on our materials to produce precision-engineered components that meet strict regulatory requirements for performance, emissions, and safety. Our metallurgists work closely with engineering teams to:

- Select the optimal steel grade for each application

- Optimize heat treatment and machining processes for maximum efficiency

- Ensure consistent quality from prototype to large-scale production

This results in lighter components for improved fuel efficiency, stronger parts for enhanced crash safety, and manufacturing processes that keep pace with the high demands of modern automotive production.

Commercial Vehicle OEMs

The commercial vehicle sector demands durability, strength, and reliability — qualities at the core of our steel solutions. From long-haul trucks to heavy-duty construction vehicles, our steels help OEMs meet growing demands for lower weight, higher load capacity, and improved safety. We collaborate directly with commercial vehicle manufacturers to:

- Reduce vehicle weight without compromising structural integrity

- Increase wear resistance in components exposed to heavy loads and abrasive environments

- Develop custom profiles and forged parts for frames, cabs, and drivetrain systems

Our commitment to material innovation means we continually improve steel grades to address new challenges in electrification, emissions reduction, and advanced manufacturing.

Partnering with Tier Suppliers

Suppliers across the automotive industry face intense pressure to meet OEM quality requirements, reduce costs, and maintain fast turnaround times. Our steel helps them achieve all three.

Key advantages for suppliers include:

- Consistent quality for repeatable manufacturing results

- Advanced metallurgical properties that reduce scrap rates and rework

- Global technical support for problem-solving and process improvement

- Compliance with international automotive standards (including IATF 16949)

By integrating our steels into their production processes, suppliers gain a competitive edge delivering components that meet the highest standards while protecting profitability.

Why the Automotive Industry Chooses Us

- Proven track record: Decades of experience serving global OEMs and top-tier suppliers

- Innovation leadership: Ongoing research into new steel grades for lighter, stronger, and more sustainable vehicles

- Technical partnership: Direct collaboration with customers to solve manufacturing challenges

- Global reach, local service: Worldwide supply network with expert support in every major automotive hub

From the smallest precision component to the largest structural frame, our steel enables the automotive industry to push boundaries, meet market demands, and drive the future of mobility.

Contact us for further information

Fields marked with * are mandatory.