Ready to go!

Steel E-Motive vehicle concept proves the potential of steel

Safe, environmentally friendly, economical in production and operation, the lowest lifecycle emissions—tomorrow's mobility solutions must meet certified requirements. The Steel E-Motive project of WorldAutoSteel, a global consortium of 18 companies, shows how this is possible. Ready-to-produce steel car body designs for autonomous electric vehicles have been developed that impressively demonstrate the advantages of using modern steel products (AHSS). As a pioneer and leader in the development of innovative steels for the automotive industry, voestalpine is a member of the core team.

The concept

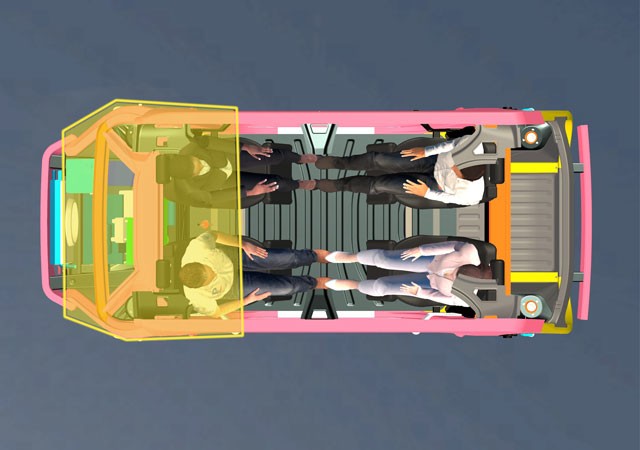

In cooperation with Ricardo, a development service provider, a concept for fully autonomous ride-sharing vehicles was developed in two different versions (for four or six persons). As the world's first steel car body concept for autonomous Mobility as a Service (MaaS) applications, the solution supports a sustainable, safe and affordable future on the road with zero-emission transport in urban areas and demonstrates the role that modern steel can play.

Benefits in industry, manufacturing and the environment

The innovative vehicle design offers a sustainable source of ideas and inspiration, not least because development focused on efficient feasibility as well. The results are summarized in a comprehensive engineering report that provides additional data and CAD models.

Download the engineering report at steelemotive.world

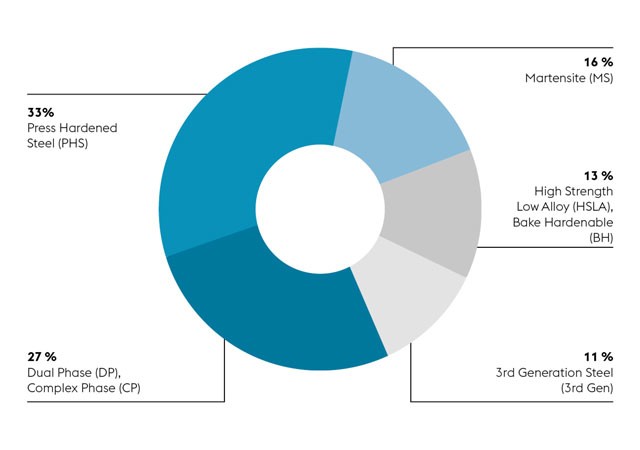

The optimum steel for every application

The Steel E-Motive concept shows how innovative steels can solve challenges in lightweight design and safety. Steel is not only one of the strongest materials in the world today, but it is also flexible, durable, environmentally friendly and nearly 100% recyclable. The modern steel developments of recent years have given car manufacturers a high degree of freedom in design and efficient production. voestalpine offers an extensive portfolio of innovative steels for cold and hot forming as well as processing expertise. This expertise is also an integral part of the Steel-E-Motive concept.

Features of the Steel E-Motive vehicle concept

- CO2 reduction potential (in contrast with comparable vehicle designs): roughly 86% throughout the vehicle lifecycle

- Weight reduction (in contrast with comparable vehicle designs): roughly 25%

- Battery packaging (in contrast with comparable vehicle designs): roughly 37% lighter and 27% cheaper (designed for maximum battery volume)

- The world's first autonomous vehicle to meet global high-speed accident safety regulations and to be awarded the "Good" rating of IIHS

- Average tensile strength of the body structure: 1259 MPa

- Compact size: Minimum front and rear overhang

- Easy entry and exit with scissor doors (without B pillar)

- Efficient large-scale production (250,000 plus) and possible use of existing manufacturing infrastructures

Further details and further information on the design can also be found at www.steelemotive.world or www.worldautosteel.org.