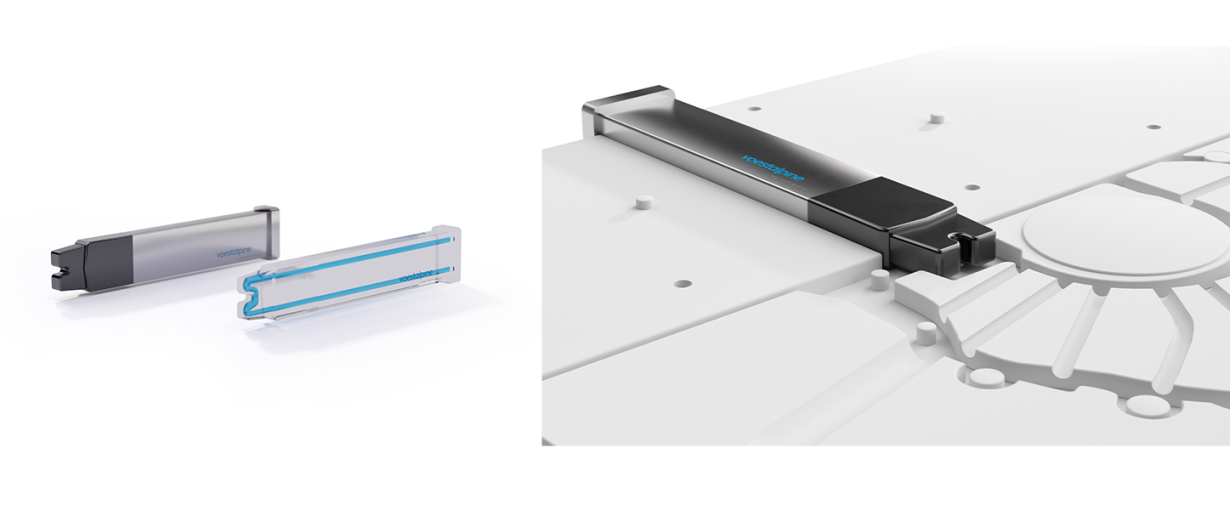

voestalpine Sub Inserts

designed for pure performance

Engineered Products

Sub Inserts for High & Low Pressure Die Casting

Sub inserts are frequently used to cast intricate designs and in critical areas of wear. Due to the extremely high thermal loads in combination with extremely hot temperature wear on these exchangeable parts, they are one of the most critical components in HPDC and LPDC tools. With constantly rising Al-part complexity, more and more sub inserts are required in DC molds. Our voestalpine Sub Inserts are the solution to these industrial challenges. These ready-to-use components are made from premium materials by BÖHLER/Uddeholm and incorporate several state-of-the-art services, including machining, heat treatment and PVD coating. With this outstanding combination, productivity and lifetime are significantly increased.