Taking a closer look at colofer® reveals what sets it apart from others.

colofer® is much more than just organic-coated steel strip. colofer® is an inspiring product that creates added value for customers, which translates into superior quality and performance along the entire value chain.

Thanks to a special substrate manufacturing process called ultraplan, colofer® plus has an extremely flat surface free of medium waviness of the carrier material. Thanks to the high-precision design, colofer® façades not only look particularly aesthetic as a result of their high-quality coating, but also because of their perfectly flat surface.

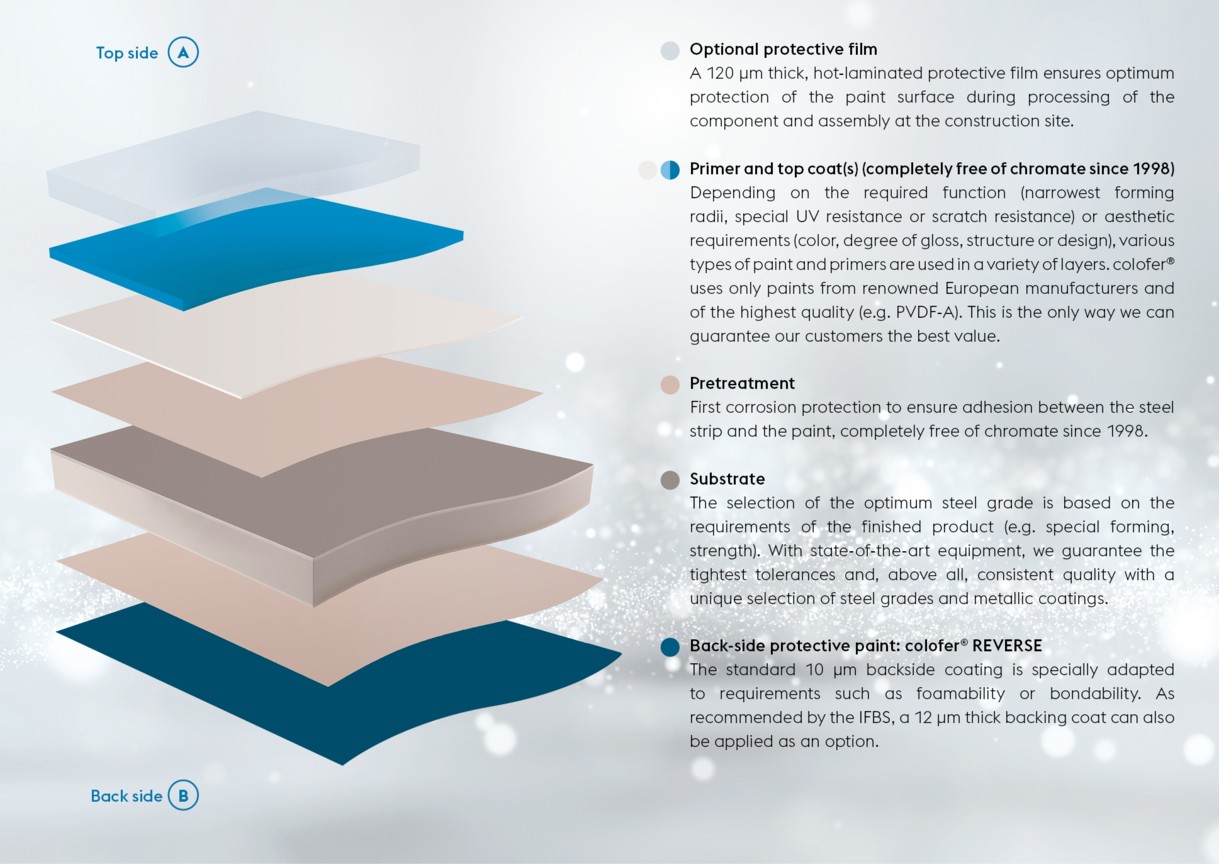

Every layer is important.

colofer® is a highly complex product consisting of a wide variety of components of the highest quality, each of which plays an important role in meeting customer requirements. With our deep understanding of this complex interaction, we always provide our customers with the optimum overall package.

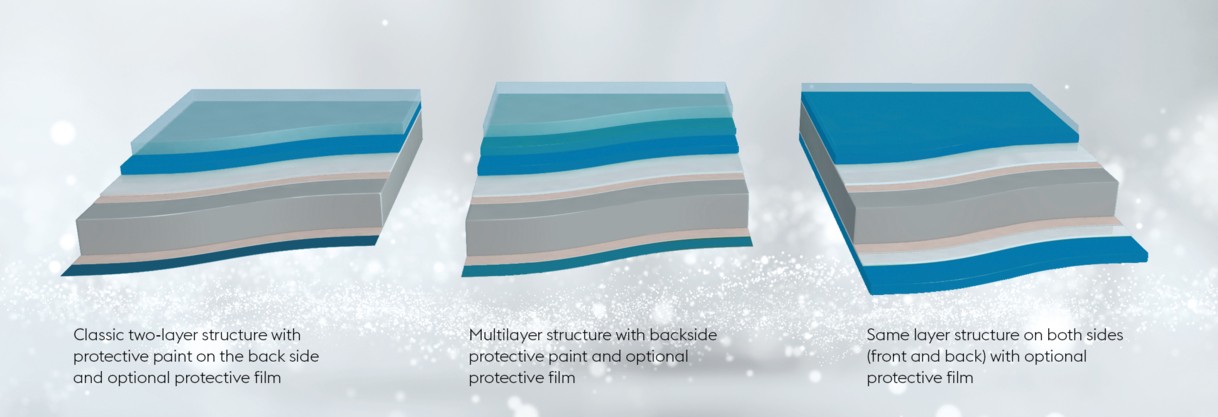

Different paint structures depending on product requirements

At first glance it seems like there are other products that are similar, but upon closer examination, they are not. For example, colofer® has been produced in a completely chrome- and chromate-free process since 1998. However, this does not affect the length of our warranties (up to 40 years) and the high levels of corrosion protection (RC 5). High-tech steel strips produced by voestalpine and paints from renowned European manufacturers in connection with our strong customer orientation make colofer® an all-round carefree package for processing companies and end users. Building on our vast experience and network of high-quality suppliers and research institutions, we can offer solutions that meet even the most demanding requirements.