Advanced technological expertise for true added value

One of the most important skills to be mastered by anyone who wants to shape the future in a sustainable way is this: Being able to listen carefully to what others have to say. We take a close look at the products and processes of our customers and talk with them about how we can provide benefits. True added value and economic success can only be achieved when the benefits exceed the costs.

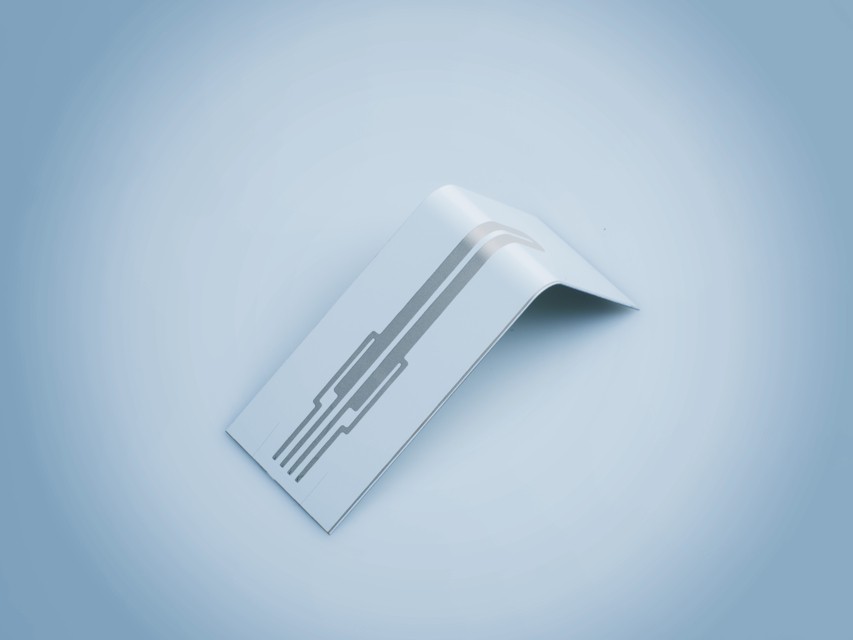

Functionality directly integrated into the component

The layered structure of tfs is a fundamental advantage: The function or sensor technology is directly integrated into the coating layer. This saves space and work steps in the production process and provides innovative design possibilities with invisible features.

Freedom in appearance and function

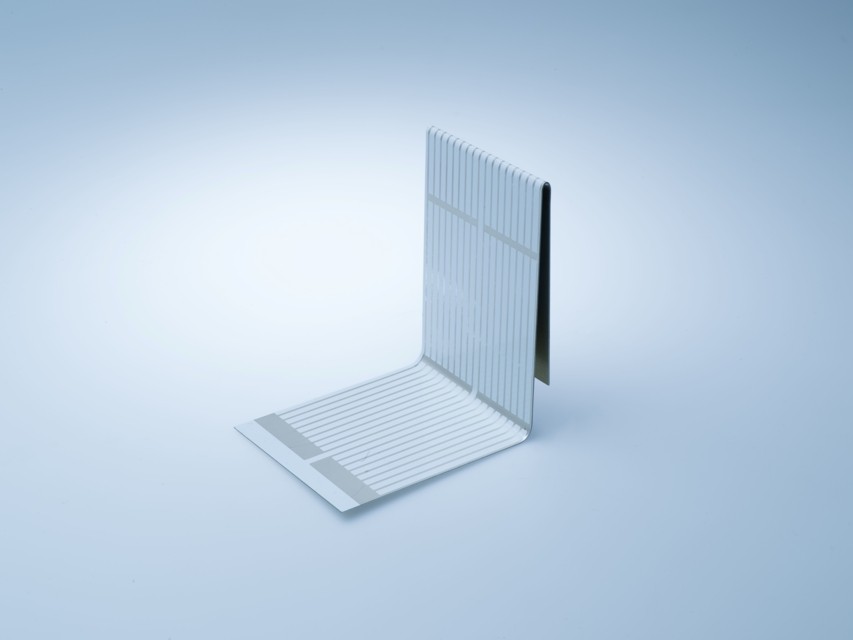

Conductor tracks are tailored to customer requirements and adapted to functional requirements such as heating power. Several functions can be combined on a single blank. Complex designs can be implemented thanks to the dimensional stability of the material and formability of the coating layer.

The maximum blank size is 1250 x 2500 mm. Several components with smaller dimensions can be arranged and printed on a single blank.

Material. Digital. Phenomenal.

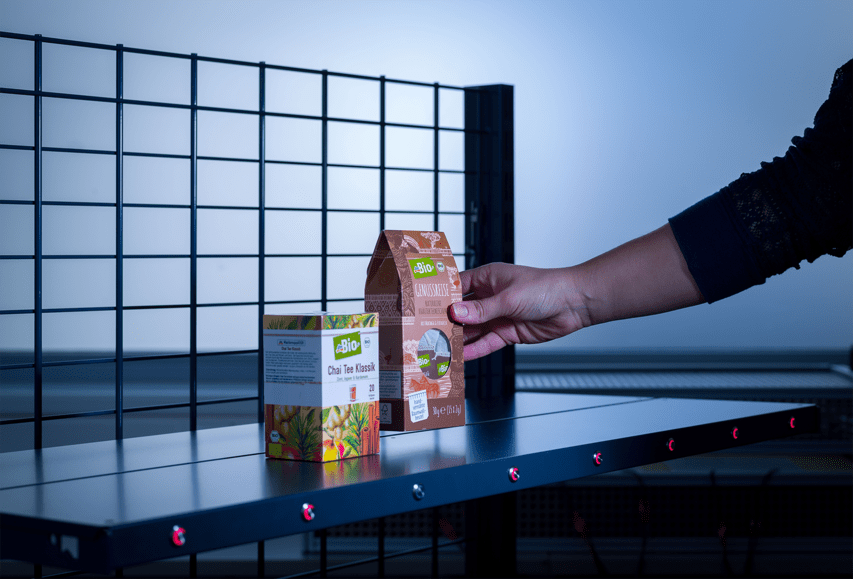

So many different things are being networked in our modern world. The Internet of Things, IoT for short, is a key driver of progress. For the first time, tfs technology offers the possibility of digitizing steel as a material to create the possibility of recording data directly on the steel surface and forwarding it in real time. Steel is becoming a smart product.

Everything from a single source

The mastermind behind tfs is voestalpine, a world-leading steel and technology group that works together with dynamic partners in providing sustainable and innovative products and solutions. The printed blank with tailored functions, customized shapes and sizes also includes the required connection and electronic components in the final scope of delivery.

You can rely on our comprehensive network of partners for further processing, including powder coating and mechanical processing. You will receive an innovative and completed solution with minimized organizational expense if you opt for our all-round carefree package.

Sustainability through and through

Unnecessary cable clutter, plug connections and large amounts of electrical waste products are a thing of the past with tfs. The conductor tracks are integrated directly into the coating layer to reduce the number of required components, conserve important resources and protect the environment. Electronic components can easily be separated from the steel substrate at the end of their service life and recycled.