Steel Division

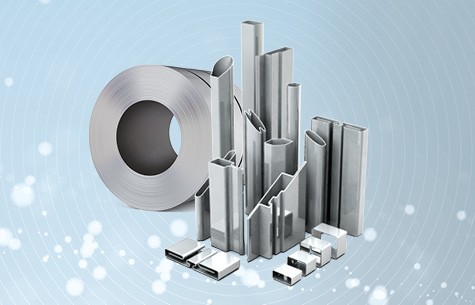

The Processing Industry subsegment of the Steel Division supplies high-quality steel strip products for the production of tubes and sections. The wide range of steel grades and high level of processing expertise at voestalpine provide the optimum foundation for individual applications that are tailored to your needs. Despite all the diversity, one thing always remains the same: You will find voestalpine quality in every product that leaves our plant.

Steel strip made by voestalpine keeps its promise: Highest quality standards in every respect. Quality lays the foundation for excellence in your products, and that is why quality is our highest priority. As a leader in steel products, voestalpine offers manufacturers of tube and section products both manufacturing and processing expertise from a single source. This expertise is the basis for a diverse product portfolio, the highest level of consulting professionalism and, above all, maximum consistency in every matter of quality.

Highly innovative industries such as the automotive industry place high demands on the tubes and profiles used in many different applications, whether it be a seat rail, a strut, in the car body or the frame. In addition to different functions, they all have one demand in common: It always has to be simplest solution possible. High-strength and ultra-high-strength steels made by voestalpine make a very special contribution here.

Materials customized by voestalpine to make tubes and sections can be used to manufacture highly complex structures. The specialized technical specialists at voestalpine have a very high degree of material and processing expertise in the field of tubes and sections. In collaboration with business partners, voestalpine has developed solutions that achieve much more than merely meet the requirements.

Many decades in steel production and processing have made one thing clear: Together we can achieve more. More consistency, more efficiency and above all more quality. As a voestalpine customer, you benefit from expert advice along the entire value chain. Our experts help you set the right course for maximum quality as early as the product design stage and help you keep quality management on track throughout the production process.

Highest consistency characterizes the product quality of voestalpine as well as its loyalty to delivery deadlines. Tighter production cycles require optimized production processes, which in turn depend on reliable supply chains. As a supplier of top-quality steel products, voestalpine offers you competent service and reliable time management. Adherence to the jointly defined delivery targets ensures that your products are manufactured right on time.

voestalpine is one of the world's leading suppliers in steel production and processing. As part of the Steel Division, the Tube and Profile Industry segment can draw on a unique range of steel grades which, based on your requirements, are the materials used in highly specialized steel strip products. The expertise of voestalpine is built on a strong foundation: Decades of experience. The highest quality standards have become the norm at our company.

The quality of hot-rolled steel strip made by voestalpine is convincing. With hot-rolled Q, voestalpine offers quality properties at an even higher level. Thanks to advanced plant operation, hot-rolled steel strip can now be customized to an even greater extent and can be geared to specific quality requirements. The high customizability of hot-rolled Q enables customers to achieve the best material properties for their applications. This puts you one step ahead, especially in the tube and profile industry.

Surface treatments made by voestalpine A multifaceted plus in the functionality and quality of steel strip. As a market-leading company, it is not enough for voestalpine to only manufacture products with outstanding material properties. Innovative surface treatments lead to an improvement to the existing properties when compared to the base material. They extend the fields of application and generate additional benefits that can be tailored to individual customer requirements.

As a works-based SSC Group in the voestalpine Steel Division, we are the center of competence for the preprocessing of steel strip and heavy plates. Maximized supply security, on-time delivery performance and customer proximity are very important to us: We work hand in hand with our customers to ensure optimized solutions and added value.

One of the highest priorities of voestalpine is to make steel available for groundbreaking applications with ever continuing innovation. An important step in this direction has now been taken with superslit, the most modern hot-rolled strip slitting line in Europe. Many new possibilities have become available in 2021 in the field of high-strength hot-rolled steels.

The application of corrender, hot-dip galvanized steel strip with a zinc-magnesium-aluminum coating, opens up completely new possibilities of optimizing your product and processes.

Improved corrosion protection was verified in several tests over various periods of time. The excellent material properties will lead to higher profitably in your products.