What are cold roll formed profiles?

Cold-formed profiles are steel profiles that are formed at room temperature. Rolling steel profiles into the desired shape is done in several steps.

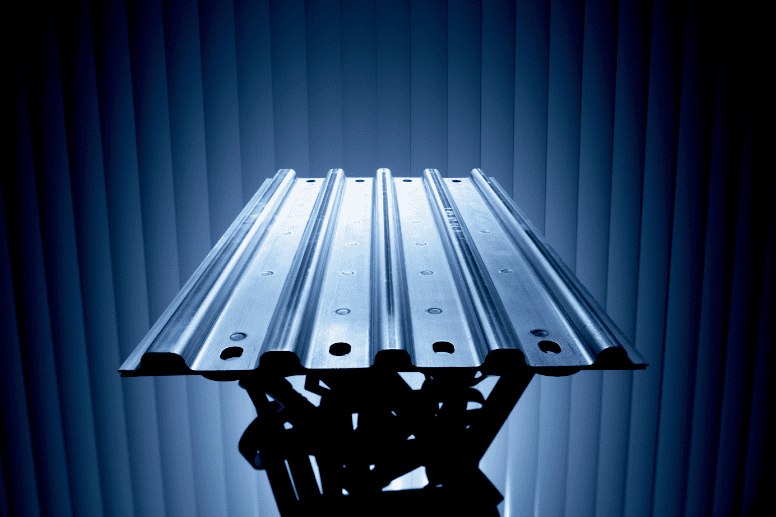

Cold-formed profiles are known for their precise dimensions and constant thickness of the material. We are happy to help you configure your profiles.

You can contact us for cold-formed U-profiles and cold-formed angle profiles, but also for very complex profiles, custom made for your project.

The main differences between hot-formed and cold-formed profiles

Hot-formed and cold-formed profiles are both valuable options in the construction industry, but they differ in important ways.

The choice between the two depends on the specific requirements of the building project, such as desired shape complexity, strength and cost considerations.

Temperature range

- When hot forming profiles, the steel is heated to high temperatures, usually above 1,000 degrees Celsius, making the material easier to deform. This allows steel profiles to be created with greater ductility and in more complex shapes.

Formability

- Cold-formed profiles are formed at room temperature, without heating the steel. Although this process offers less flexibility in creating complex shapes, it has its own advantages. Cold-formed profiles are generally characterised by a higher degree of accuracy and dimensional consistency, resulting in better fit and assembly on site.

Strength

- Cold-formed steel generally has higher strength than hot-formed steel. This makes cold-formed profiles suitable for applications where high loads and strength are required.

Cost difference

- In general, cold-formed profiles are more cost-effective in terms of production and material costs. The process at room temperature requires less energy and time, reducing production costs.

Some characteristics of hot-formed and cold-formed profiles

Cold-formed steel

- Clear, metallic surface

- Usually a smooth surface

- Lighter in weight

- Minimum sheet thickness for cold rolling is approx. 0.10 mm

- Stronger (harder)

- Lower degree of elongation (toughness) and formability

Cold-formed steel

- Often darker in colour

- Often somewhat rougher surface

- Often heavier (per section)

- Only available in thicknesses from approx. 1.5 mm onwards

- Less hard

- Greater elongation (toughness) and formability

From sheet to profile: The process of cold forming

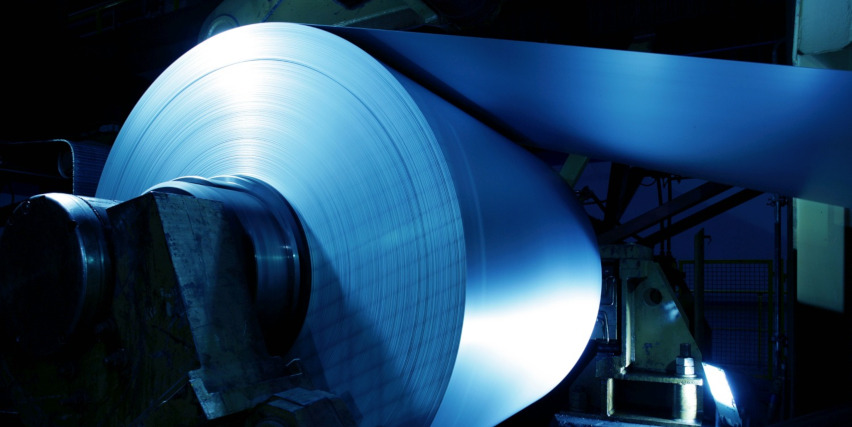

During the cold forming process, we transform flat sheets or strips of steel into cold-formed profiles with various shapes and cross-sections. This exciting process starts with the selection of high-quality steel suitable for cold forming.

The steel sheets are then cut to the desired width and thickness.The actual forming process begins when the sheets are passed through a series of rollers that gradually give the desired shape to the steel. Due to the pressure and forming force of the rollers, the steel is deformed and takes the desired profile shape.

These rollers can have different shapes, depending on the desired end result.During the cold forming process, the steel undergoes permanent plastic deformation, maintaining its new shape. After forming, the cold-formed profiles are cut to size and further processed if needed, such as making holes or adding specific finishes.

Our approach for creating the best steel profiles

At every stage of the development process, from a rough sketch to parts ready for assembly, voestalpine Sadef offers creative, innovative and cost-effective ideas and competitive concepts that will lead to an optimized solution for your project.

From concept to commercial & technical agreement

- 1. Concept from the customer

- 2. Co-engineering: optimization of the customer's needs

- 3. Commercial and technical agreement

- 4. Tooling engineering

- 5. Prototype and approval by customer

- 6. Production drawing

Van productietekening tot koudvormen & levering vormen

- 7. Roll-forming / cold-forming / cold-profiling

- 8. Further rework (such as welding, laser cutting, bending,...)

- 9. Quality control

- 10. Packaging & delivery

Applications - customised cold-formed steel profiles

The applications of these steel profiles are practically endless and we are therefore a supplier for ready-to-use steel components in a wide range of industries. For instance, we produce for the following sectors: construction, solar, industry, cabins, mobility... Curious to find out more or about some specific applications? Then take a look at our market sectors page.

Voestalpine Sadef - Specialist in cold-formed steel profiles

Are you looking for a reliable supplier of cold-formed steel profiles for conveyors, high rack warehouses, mechanical engineering, ventilation applications, crane and lifting systems, construction applications and so much more? Then voestalpine Sadef is the right partner for you.

With our 35 profiling lines, we make cold-formed steel profile solutions for a wide range of industries and deliver customized steel profiles that are light, easy to assemble and, if desired, finished with a powder coating.

Thanks to continuous investments and adjustments, our production site is a leader in the sector, always one step ahead. Through co-engineering, our own team of experts ensures that every customer can realize his project with an optimized steel profile. This way we are a real profile solutions provider for your business.

Contact us

Are you interested in our steel profiles? Please contact our sales team using the buttons on the right or our contact form.