FILTERS FOR PLASTIC INJECTION MOLDING

Nozzle filters are used to prevent contamination from the plastic melt causing blockages or interruptions to the injection process. These contaminates can cause damage to hot runner systems resulting in extended downtime and increased maintenance costs.

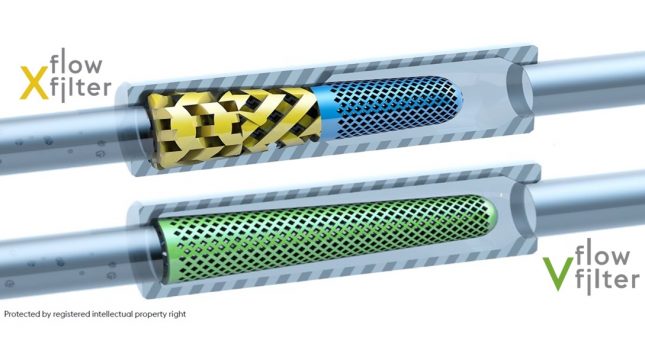

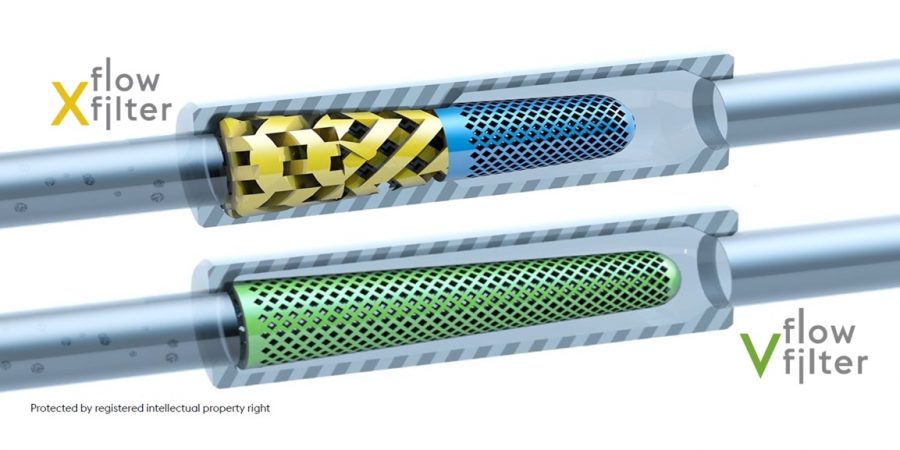

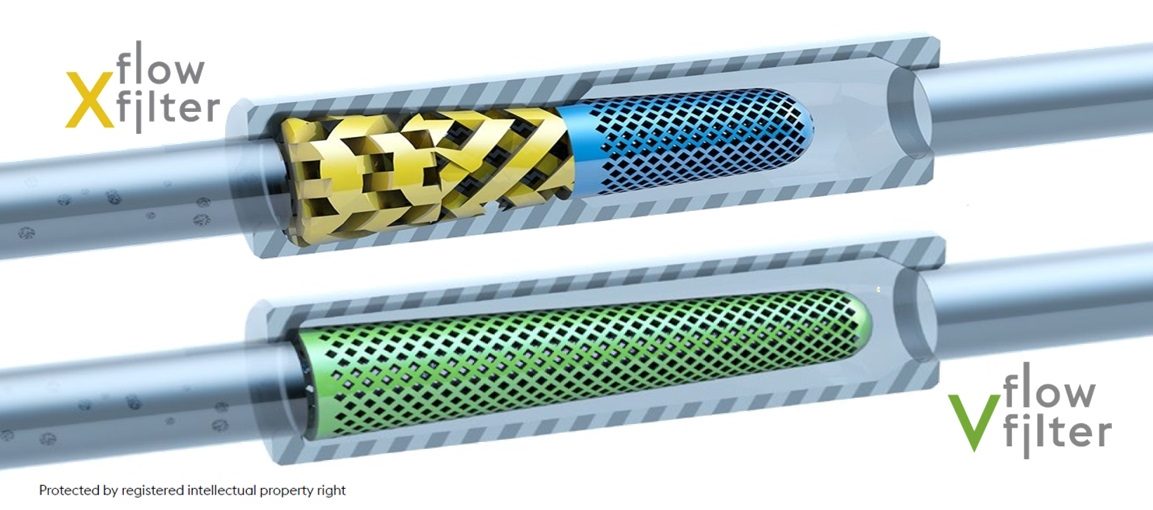

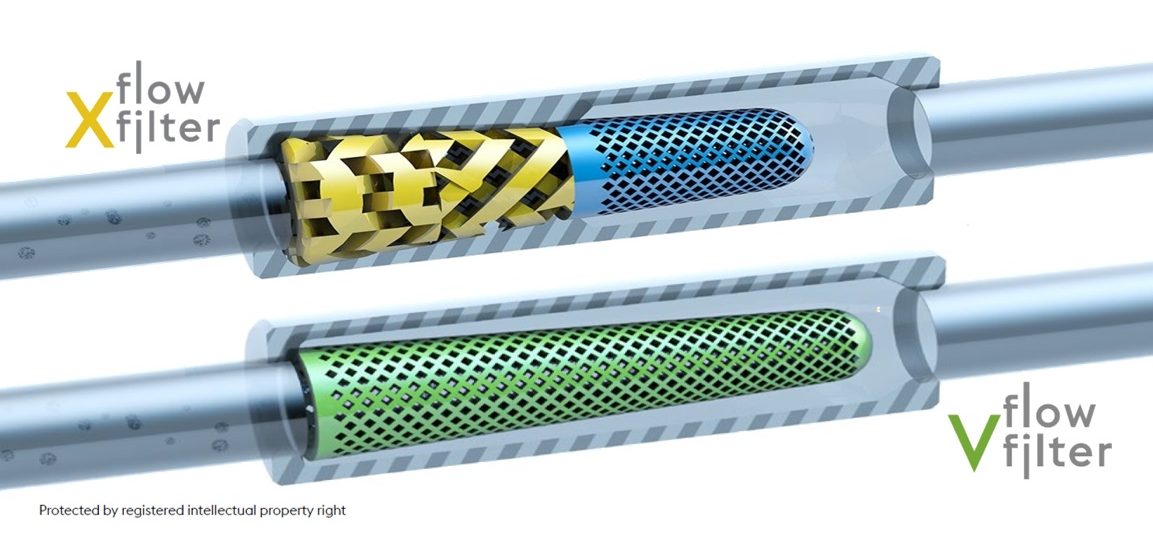

The design of the voestalpine flow filters capitalize on the unique capabilities of 3D printing to integrate static mixers and filters into a compact form factor, delivering both ease of installation and improved performance over traditional injection molding nozzle filters.

The unique material flow design of the flow filter results in a significant reduction in pressure drop typically associated with traditional injection molding nozzle filters, giving additional benefits such as reduced machine wear and energy consumption.

Each filter is manufactured using UDDEHOLM AM CORRAX. This dedicated Plastic Injection Mold steel has been specifically designed for additive manufacturing applications, it properties ensure the highest possible molding performance due to its increased corrosion and wear resistance.

The design of the voestalpine flow filter X capitalizes on the unique capabilities of 3D printing to integrate a static mixer and filter into a standard form factor, delivering improved performance over traditional injection moulding nozzle filters.

This configuration of in-line static mixer and filter helps prevent feed blockages caused by material impurities, such as those encountered when processing recycled materials and delivers superior mixing properties when using additives.

CHARACTERISTICS |

BENEFITS |

| Combines filter and mixer in one single component | Trouble-free injection molding |

| Large filtration area | Lower maintenance and downtime costs |

| Small mesh size | Space-saving installation |

| Good mixing properties | Better part quality |

| Low pressure drop | Only slight increase in injection pressure |

| Low shear stress | Easy cleaning |

| Corrosion resistant | Long lifetime |

| Wear resistant |

The design of the voestalpine flow filter V capitalizes on the unique capabilities of 3D printing to integrate a high density solid mesh filter into a standard form factor, delivering improved performance over traditional injection moulding nozzle filters.

This configuration of high density solid mesh filter helps prevent feed blockages caused by material impurities, such as those encountered when processing recycled materials while minimizing overall pressure drop.

CHARACTERISTICS |

BENEFITS |

| Extremely low pressure drop | Trouble-free injection molding |

| Very low shear stress | Minimal increase in injection pressure |

| Small mesh size | Lower energy consumption |

| Very large filtration area | Lower maintenance and downtime costs |

| Corrosion resistant | Better part quality |

| Wear resistant | Easy cleaning |

| Long lifetime |

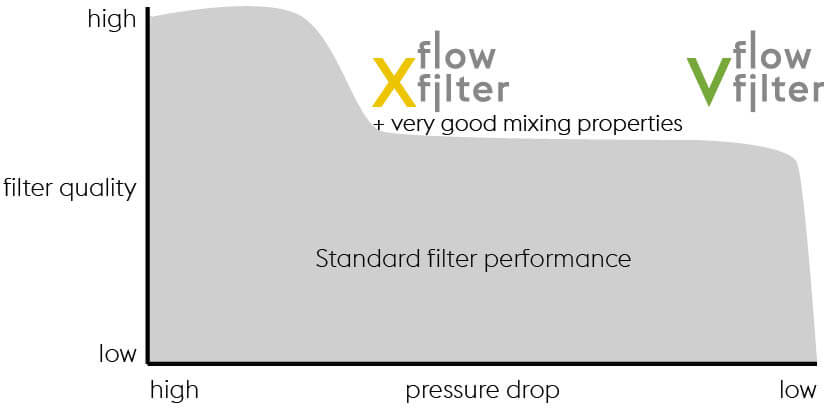

FEATURE COMPARISON

- flow filter X should be selected if improved mixing performance is required in conjunction with high quality filtration.

- flow filter V should be selected for high quality filtration with minimum overall pressure drop.

- Pressure drop and shear stress can be influenced by many parameters (eg injection material, filler material, temperature, etc).

- voestalpine flow filters are not recommended for glass fiber reinforced plastics.