Materials

BÖHLER Edelstahl GmbH

BÖHLER Edelstahl GmbH

Dimensionen

| Cross sections of round billets | BAR forged |

| Surface ground to remove defects | round: 110 – 1200mm (4.3 – 47.24″) |

| or bright ground 100 – 1200 mm (3.94 – 47,24″) | square: 90 – 1200mm (3.54 – 47.24″) |

| with peeled surface 100 – 425 mm (3.94 – 16.73″) | flat: width, mm (inch) thickness, mm (inch) |

| with turned surface 425 – 900 mm (16.73 – 35.43″) | 120 (4.72) 50 (1.97) min. |

| Ratio width / thickness maximum 10:1 | |

| Cross sections of square billets | |

| Surface bright ground 100 – 600mm (3.94 – 23.62″) | |

| BAR pre-machined | |

| BAR rolled | IBO ECOMAX: 12.5 – 425 mm (0.49 – 16.73″) |

| round: 12.5 – 150 mm (0.49 – 5.91″) | |

| square: 15 – 130 mm (0.59 – 5.12″) | BRIGHT STEEL |

| flat: width, mm (inch) thickness, mm (inch) | ECOBLANK peeled and polished |

| 15 – 60 (0.59 – 2.36) 5 – 41 (0.20 – 1.61) | ECOFINISH band ground |

| 60 – 200 (2.36 – 7.87) 5 – 86 (0.20 – 3.39) | BRIGHT BAR ground and polished |

| 100 – 300 (3.94 – 11.81) 15 – 80 (0.59 – 3.15) | |

| Open die forgings | |

| ROLLED WIRE | premaschined or ready machined according to |

| rolled: dia. 5.0 – 13.5 mm (0.20 – 0,53″) | customer requirements, up to 45 tons. |

| drawn: dia. 1.0 – 12.0 mm (0.04 – 0,47″) |

Duplex and super-duplex grades

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

| BÖHLER A903 | 1.4462

S31803 / S32205 |

F51 | Airmelted | X2CrNiMoN 22-5-3 | Norsok-M-650 (MDS D47, size mill request necessary)

DIN EN 10088-3 ASTM A182, A276, A479 |

Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

|

| BÖHLER A911SA | 1.4501

S32760 |

F55 | Airmelted | X2CrNiMoCuWN 25-7-4 | Norsok-M-650 (MDS D47, size mill request necessary)

DIN EN 10088-3 ASTM A182, A276, A479 |

Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

|

| BÖHLER A913 | 1.4410

S32750 |

F53 | Airmelted | X2CrNiMoN 25-7-4 | Norsok-M-650 (MDS D47, size mill request necessary)

DIN EN 10088-3 ASTM A182, A276, A479 |

Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

|

| BÖHLER A930 | 1.4507

S32550 |

F61 | Airmelted | X2CrNiMoCuN 25-6-3 | DIN EN 10088-3

ASTM A182, A276, A479 |

Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

Austentics

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

| BÖHLER A220 | 1.4435

S31603 |

316LUG | Airmelted + ESR | X2CrNiMo 18-14-3 | STAC 18005

DIN EN 10088-3 ASTM A182, A276, A479 |

Round bar: 12.5 – 600 mm (0.5 – 23.62″)

vFlat bar, Billet |

|

| BÖHLER A405 | 1.4466

S31050 |

310MoLN | Airmelted + ESR | X2CrNiMoN 25-22-2 | STAC 18005

DIN EN 10088-3 ASTM A182 |

Round bar: 12.5 – 600 mm (0.5 – 23.62″)

Flat bar, Billet |

|

| BÖHLER A959 | Alloy 28 | 1.4463

N08028 |

Airmelted | DIN EN 10088-3 | Round bar: 12.5 – 203.2 mm (0.5 – 8″)

Billet |

||

| BÖHLER A965SA | 1.4547

S31254 |

F44 | Airmelted | X2CrNiMoCuN 20-18-7 | Norsok-M-650 (MDS R17, size mill request necessary)

DIN EN 10088-3 ASTM A182, A276, A479 |

Round bar: 12.5 – 228.6 mm (0.5 – 9″)

Billet |

|

| BÖHLER A970 | 1.4529

N08926 |

Airmelted | X2CrNiMoCuN 25-20-7 | DIN EN 10088-3

ASTM B649 |

Round bar: 12.5 – 228.6 mm (0.5 – 9″)

Billet |

||

| BÖHLER P511 | XM-19 | S20910 | Airmelted | X2CrNiMoCuNbN 21-13-3 | ASTM A276, A479, A182 | Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

|

| BÖHLER P513 | S21800 | S21800 | Airmelted | ASTM A276, A479, A193, A194, AMS 5848 | Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Flat bar, Billet |

||

| BÖHLER T200 | 660

A286 |

1.4980

S66286 |

Airmelted + ESR | X5NiCrTi 26-15 | VdTÜV 435

DIN EN 1029, 10302 ASTM A453 AMS 5731, 5732 |

Round bar: 12.5 – 254 mm (0.5 – 10″)

Flat bar, Billet |

Nickel Base Alloys

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

| BÖHLER L625 | Alloy 625 | 2.4856

N06625 |

VIM + ESR | NiCr22Mo9Nb | AMS 5666

ASTM B446, B564 |

Round bar: 12.5 – 254 mm (0.5 – 10″)

Flat bar, Billet |

|

| BÖHLER L725 | Alloy 725 | N07725 | VIM + VAR | API 6A CRA

NACE MR01725 / ISO15156 |

Round bar: 12.5 – 203.2 mm (0.5 – 8″)

Billet |

||

| BÖHLER L825 | Alloy 825 | N08825

N08028 |

Airmelted | ASTM B425 | Round bar: 12.5 – 304.8 mm (0.5 – 12″)

Billet |

||

| BÖHLER L750 | Alloy X750 | N07750 | VIM + VAR | ASTM B637

NACE MR0175 /ISO15156 |

Wire: 5 – 15.5 mm (0.2 – 6″)

|

||

| BÖHLER L925 | Alloy 925 | N09925 | VIM + VAR | NiCr21TiCuMo | API 6A CRA

NACE MR0175 /ISO15156 |

Round bar: 12.5 – 355.6 mm (0.5 – 14″)

Billet |

|

| BÖHLER L718API | Alloy 718API | N07718 | VIM + VAR | NiCR19NbMo | API 6A CRA

NACE MR0175 /ISO15156 |

Round bar: 12.5 – 355.6 mm (0.5 – 14″)

Flat bar, Billet |

|

| BÖHLER L718AMS | Alloy 718AMS | 2.4668

N07718 |

VIM + VAR | NiCR19NbMo | AMS 5662

ASTM B637 AMS 5663 |

Round bar: 12.5 – 203.2 mm (0.5 – 8″) | |

| BÖHLER L059 | Alloy 59 | 2.4605

N06059 |

VIM + ESR | NiCR23Mo16AI | ASTM B574 | Round bar: 12.5 – 203.2 mm (0.5 – 8″)

Flat bar, Billet |

|

| BÖHLER L276 | Alloy 276 | 2.4819

N10276 |

VIM + ESR | NiCR21Mo14W | VdTÜV 400 (max. 360 mm/~14″) ASTM B564, B574 NACE MR0175 | Round bar: 12.5 – 355.6 mm (0.5 – 8″)

Flat bar, Billet |

|

| BÖHLER L004 | Alloy 004 | 2.4610

N06455 |

VIM + ESR | NiMo16Cr15W | VdTÜV 424 (max. 360 mm/~14″) ASTM B574 NACE MR0175 /ISO15156 | Round bar: 12.5 – 355.6 mm (0.5 – 8″)

Flat bar, Billet |

|

| BÖHLER L022 | Alloy 022 | 2.4602

N06022 |

VIM + ESR | NiMo16Cr16Ti | VdTÜV 479 (max. 360 mm/~14″) ASTM B564, B574 | Round bar: 12.5 – 355.6 mm (0.5 – 8″)

Flat bar, Billet |

|

| BÖHLER L035 | R30035 | R30035 | VIM + VAR | AMS 5844 | Wire: 5 – 15.5 mm (0.2 – 0.6″) |

Heat Treatable Steels

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

| BÖHLER N400 | F6NM | 1.4313

S41500 |

F6NM | Airmelted | X4CrNi 13 4 | DIN EN 10088-3

ASTM A182 |

Round bar: 12.5 – 1,040 mm (0.5 – 40.94″)

Flat bar, Billet |

| BÖHLER N404 | 1.4418 | Airmelted | X4CrNiMo 16 5 | DIN EN 10088-3 | Round bar: 12.5 – 500 mm (0.5 – 19.68″)

Flat bar, Billet |

PH Grades

| Brand | Market Grade | UNS | ASTM | Melting route | Others | Industry Specifications | Products and Size Range |

| BÖHLER N700SA | 17-4 PH | 1.4542 | 630 | Airmelted | X5CrNiCuNb 17 4 | DIN EN 1008-3

ASTM A564 |

Round bar: 12.5 – 203.2 mm (0.5 – 8″)

Flat bar, Billet |

| BÖHLER N701 | 15-5 PH | 1.4545 | XM 12 | Airmelted +VAR | X5CrNiCuNb 15 5 | ASTM A564 | Round bar: 12.5 – 203.2 mm (0.5 – 8″)

Flat bar, Billet |

BÖHLER Bleche

BÖHLER Bleche

Dimensions

| Dimensions hot rolled | Surface finish |

| Width max. 2,000 mm | As rolled |

| Length max. 7,000 mm | Shot blasted |

| Thickness 2.0 mm up to 90.0 mm | Pickled |

| Weight max 3,000 kg | Ground |

| Milled | |

| Dimensions cold rolled | |

| Width max. 1,350 mm | Minimum order quantities |

| Length max. 5,000 mm | Standard alloys (output of one slab) |

| Thickness 1,0 mm up to 6.0 mm | Steel 800 – 3,000 kg |

| Ni-base-alloys 800 – 2,200 kg | |

| Edge finish | Titanium 600 – 1,100 kg |

| Shear cut | |

| Laser cut | Special alloys (output of one melt) |

| Cold sawn | VID 6-8 |

| Plasma cut | EAF-VOD 25 – 35 to |

| Water jet cut | VIM 4 alt. 10 to

(Ni-base-alloys) |

Corrosion Resistant Alloys

| Type of Alloy | Brand | PREN | Common name | DIN / EN | UNS | Standards | Main Applications |

| Martensite | BÖHLER N100 | AISI 410 | 1.4006 | ASTM A240

EN 10088-2 |

Engineering

Equipment, Turbines |

||

| Martensite | BÖHLER N400 | 1.4313 | EN 10088-2 | Engineering

Equipment |

|||

| Martensite | BÖHLER N700 | 17-4 PH

AISI 630 |

1.4542 | S17400 | ASTM A693

EN 10088-2 |

Offshore Industry | |

| Superduplex | BÖHLER A9115SA | 41 | 1.4501 | S32760 | ASTM A240

Norsak MDS D55 Shell-Spez. ES/247 |

Offshore Industry

Water Treatment |

|

| Superduplex | BÖHLER A913 | 40 | 1.4410 | S32750 | ASTM A240

Norsak MDS D55 Shell-Spez. ES/247 |

Offshore Industry

Water Treatment |

|

| Superduplex | BÖHLER A924 | 40 | ~1.4507 | S32550

S32520 |

ASTM A240 | Offshore Industry | |

| Super Austenite | BÖHLER A610 | 1.4361 | S30600 | ASTM A240

Bayer WN 950 EN 10088-2 |

Nitric Acid Production, Storage | ||

| Super Austenite | BÖHLER A611 | S30601 | ASTM A240

VdTÜV 534 |

Sulfuric Acid Production, Storage | |||

| Super Austenite | BÖHLER A614 | ~1-4469 | S32615 | ASTM A240

VdTÜV 535 |

Sulfuric Acid Production, Storage | ||

| Super Austenite | BÖHLER A657 | 1.4335 | S31002

S31008 |

ASTM A240

VdTÜV 468 |

Nitric Acid Production, Storage | ||

| Super Austenite | BÖHLER A965A | 43 | 6-Mo | 1.4547 | S31254 | ASTM A240

Norsok MDS R15 Shell-Spez. ES/247 |

Offshore Industry

Chemical Industry |

| Super Austenite | BÖHLER A952 | Alloy 31 | 1.4562 | N08031 | ASTM B625

VdTPV 509 |

Chemical and Petrochemical Industry | |

| Super Austenite | BÖHLER A970 | 42 | 1.4529 | N08926

N08367 |

ASTM B625 | Offshore Industry | |

| Super Austenite | BÖHLER H500 | Alloy 800/800H/800HT | 1.4876 | N08800

N08810 N08811 |

ASTM B409

EN 10095 SEW 470 |

Petrochemical Industry | |

| Nickel-Base | BÖHLER L022 | Alloy C22 | 2.4602 | N06022 | ASTM B575

VdTÜV 479 |

Petrochemical Industry | |

| Nickel-Base | BÖHLER L276 | Alloy C276 | 2.4819 | N10276 | ASTM B575

VdTÜV 400 |

Chemical Industry, Pharmacy | |

| Nickel-Base | BÖHLER L625 | Alloy 625 | 2.4856 | N06625 | ASTM B443

EN 10095 |

Offshore Industry | |

| Nickel-Base | BÖHLER L004 | Alloy C4 | 2.4610 | N06455 | ASTM B575

VdTÜV 424 |

Chemical Industry | |

| Nickel-Base | BÖHLER L825 | Alloy 825 | 2.4858 | N08825 | ASTM B244

DIN 17744 |

Chemical Industry | |

| Nickel-Base | BÖHLER L059 | Alloy 59 | 2.4605 | N06059 | ASTM B575

DIN 17744 |

Chemical Industry, Pharmacy | |

| Nickel-Copper | BÖHLER L400 | Alloy 400 | 2.4360 | N04400 | ASTM B127

DIN 17750 BS 3072 |

Chemical Industry | |

| Pure Nickel | BÖHLER L200 | Alloy 200

Alloy 201 |

2.4066

2.4068 |

N02200

N02201 |

ASTM B165

DIN 17750 BS 3072 |

Chemical Industry |

Heat Resistant Alloys

| Type of Alloy | Brand | Common name | DIN / EN | UNS | Standards | Main Application |

| Ferrite | BÖHLER H100 | 1.4762 | SEW 470

EN 10095 |

Industrial Furnaces | ||

| Ferrite | BÖHLER H160 | 1.4713 | EN10302 | |||

| Martensite | BÖHLER T567 | 1.4903 | EN 10302 | Turbines | ||

| Duplex | BÖHLER H300 | 1.4821 | SEW 470 EN 10095 |

Industrial Furnaces | ||

| Austenite | BÖHLER H500 | Alloy 800/800H/800HT | 1.4876 | N08800 N08810 N08811 |

ASTM B409 SEW 470 EN 10095 |

Industrial Furnaces |

| Austenite | BÖHLER H520 | ~Alloy DS | ~1.4864 | ~N08832 | ASTM B536 EN 10095 |

Industrial Furnaces |

| Austenite | BÖHLER H521 | Alloy 330 | N08330 | ASTM B536 | Industrial Furnaces | |

| Austenite | BÖHLER H525 | Alloy 314 | 1.4841 | S31400 | SEW 470 EN10095 |

Industrial Furnaces |

| Austenite | BÖHLER T200 | Alloy 286 | 1.4943 1.4944 1.4980 |

S66286 | EN 10302 | Turbines |

| Austenite | BÖHLER T240 | ~1.4962 | EN 10302 | Turbines | ||

| Austenite | BÖHLER T275 | 1.4961 | EN 10028-7 EN 10302 |

Turbines | ||

| Nickel-Base | BÖHLER L075 | Alloy 75 | 2.4951 2.4630 |

N06075 | EN10095 | Turbines, Engines |

| Nickel-Base | BÖHLER L090 | Alloy 90 | 2.4969 2.4632 |

N07090 | EN 10302 | Turbines, Engines |

| Nickel-Base | BÖHLER L263 | Alloy 263 | 2.4650 | N07263 | AMS 5872 EN 10302 |

Tubines, Engines |

| Nickel-Base | BÖHLER L602 | 2.4663 | N06025 | ASTM B168 DIN 17744 EN 10302 |

Industrial Furnaces | |

| Nickel-Base | BÖHLER L617 | Alloy 617 | 2.4663 | N06617 | ASTM B168 EN 10302 |

Turbines, Engines |

| Nickel-Base | BÖHLER L625 | Alloy 625 | 2.4856 | N06625 | ASTM B443 EN 10095 |

Turbines, Engines, Industrial Furnaces |

| Nickel-Base | BÖHLER L718 | Alloy 718 | 2.4668 | N07718 | ASTM B4670 EN 10302 |

Turbines, Engines |

Special Alloys and Titanium

| Properties | Type of Alloy | Brand | PREN | Common name | DIN / EN | UNS | Standards | Main Applications |

| Machinability | Austenite | BÖHLER A101 | ~AISI 316+S | ~1.4436+S | Screen Plates

Screen Drums |

|||

| Machinability | Austenite | BÖHLER A506 | AISI 303 | 1.4305 | S30300 | ASTM A895

EN 10088-3 |

Screen Plates

Screen Drums |

|

| Nonmagnetic | Austenite | BÖHLER P500 | 38 | ~1.4565 | ~S20910 | ASTM A240

SEW 400 |

Ship Building | |

| Nonmagnetic | Austenite | BÖHLER P501 | 35 | 1.3964 | ~S20910 | ASTM A240

SEW 390 |

Ship Building | |

| Nonmagnetic | Austenite | BÖHLER P503 | 40 | 1.3974 | SEW 390 | Offshore Industry | ||

| Nonmagnetic | Austenite | BÖHLER P512 | 43 | 1.4565 | S34565 | ASTM A240

EN 10088-2 |

Combustion Gas

Desulphurisation |

|

| Nonmagnetic | Austenite | BÖHLER P530 | ~1.3949 | SEW 390 | Electric Equipment | |||

| Expansion Coefficient | Austenite | BÖHLER P802 | Ni 36 | 1.3912 | K93600

K93603 |

SEW 385 | Laminate Moulds | |

| Expansion Coefficient | Austenite | BÖHLER P810 | NiCo 29-18 | 1.3981 | K94610 | ASTM F15

SEW 385 |

Electronic Industry |

| Type of Alloy | Brand | Common name | UNS | Material Number | Standards | Main Applications |

| Commercially Pure Titanium | BÖHLER L511 | Grade 1 | R50250 | 3.7025 | ASTM B625

VdTÜV 230 |

Industry |

| Commercially Pure Titanium | BÖHLER L511 | Grade 2 | R50400 | 3.7035 | ASTM B625

VdTÜV 230 |

Industry |

| Commercially Pure Titanium | BÖHLER L513 | Grade 3 | R50550 | 3.7055 | ASTM B625 | Industry |

| Commercially Pure Titanium | BÖHLER L514 | Grade 4 | R50700 | 3.7065 | ASTM B625

ASTM 567 ISO 5832-2 |

Industry

Medicine |

| Alloyed Titanium | BÖHLER L531B | Grade 5 | R56400 | 3.7165 | ASTM B625 | Industry |

| Alloyed Titanium | BÖHLER L531 | Grade 5 | R56400 | 3.7165 | ASTM B625

AMS 4911 |

Industry

Aerospace |

| Alloyed Titanium | BÖHLER L519 | Grade 9 | R56620 | 3.7194 | ASTM B625 | Industry |

| Alloyed Titanium | BÖHLER L533 | Grade 23 | R56407 | 3.7165 | ASTM B625

ASTM F136 ISO 5832-3 |

Medicine

Aerospace |

Villares Metals

Villares Metals

Forged Parts Restraints

| Product | Dimensions and Weight | (Rough Machined) | Limitations |

| Round Bars | D = 127 to 1.420 mm L <= 14.000 mm (lathed) D = 142 to 1.480 mm L <= 18.000 mm (raw forging) Weight <= 24.000 kg |

D <= 240 => +2/-0

D>= 240 => +3/-0 L => +10/-0 |

Bars with diameters larger than 650 mm and length longer than 7,400 mm only be supplied without heat treatment (upon consultation) or normalized or stress relieved (length up to 12,000 mm). Bars with diameter up to 215 mm can only be supplied with no length up to 14,000mm. |

| Square Bars | T = 130 to 1.250 mm L <= 12.000 mm (machined) Weight <= 22.500 kg |

T => +3/-0

L => +10/-0 |

Bars with thickness larger than 650 mm and length longer than 7,400mm can only be supplied without heat treatment (upon consultation) or normalized or stress relieved. |

| Flat Bars | T = 130 to 1.250 mm W = 130 to 2.300 mm L <= 12.000 mm (machined) Weight <= 22.500 kg |

T => +3/-0

W => +3/-0 L => +10/-0 |

Bars with thickness or width larger than 650 mm and lenght longer than 7,400 mm can only be supplied without heat treatment (upon consultation) or normalized or stress relieved. (*) Bars with width larger than 1,250 mm must have a maximum area equal to square bar area of 1,250 mm. |

| Hollow Bars | D = 203 to 1.300 mm Di = 65 to 505 mm T >= 50 mm L <= 14.000 mm Weight <= 23.000 kg |

D <= 240 => +2/-0

D>= 240 => +3/-0 Di => +/-1,5 L => +10/-0 |

The dimension of holes depends on the available tools and dimension of the parts, but in general, it varies from 65 to 505mm. Smaller holes can be supplied upon consultation, by subcontracting other machine shops. Bars with diameter larger than 650mm and length longer than 7,400mm can only be supplied without heat treatment (upon consultation) or normalized or stress relieved. |

| Disks (H<D) | D = 450 to 2.340 mm H = 130 to 1.420 mm Weight <= 22.500 kg |

D => +3/-0

H => +10/-0 |

Parts with diameter from 900 to 2,340mm can only be supplied with a height shorter than 175mm and taller than 1,420mm, upon consultation. Parts with diameter larger than 1,900mm can only be supplied normalized. |

| Rings (H<D) | D = 450 to 3.000 mm Di <= 2.000 mm H = 130 a 1.420 mm Weight <= 20.000 kg |

D => +3/-0

Di => +0/-3 H => +10/-0 |

Sum of inner diamter and thickness must be ~2,200mm. Parts with external diameter larger than 1,900mm can only be supplied without heat treatment (upon consultation) or normalized. Parts with external diameter larger than 2,000mm can only be supplied with inner diameter larger than 200mm. |

| Sleeves (L>D) | D = 500 to 2.600 mm Di = 380 to 2.000 mm L <= 4.300 mm Weight <= 20.000 kg |

D => +3/-0

Di => +0/-3 L => +10/-0 |

Sum of inner diameter plus thickness must be ~2,200 mm. Parts with inner diameter larger than 650mm can only be supplied with length up to 2,500mm. Parts with length larger than 2,000mm can only be supplied with inner diameter in the as forged condition (upon consultation). |

| Solid Blanks | D = 127 to 1.600 mm L <= 12.000 mm Weight <= 22.000 kg |

D => +3/-0

L => +10/-0 |

Parts with diameter larger than 650mm and length larger than 7,400mm can only be supplied without heat treatment (upon consultation) or normalized. |

| Flanged Shafts | D = 400 to 1.600 mm Di >= 250 mm L <= 12.000 mm Weight <= 20.000 kg |

D => +3/-0

L => +10/-0 |

Parts with diameter larger than 650mm and length larger than 7,400mm can only be supplied without heat treatment (upon consultation) or normalized. |

| Hollow Blanks | D = 127 to 1.600 mm Di = 65 to 505 mm L <= 14.000 mm Weight <= 20.000 kg |

D => +3/-0

Di => +/-1,5 H => +10/-0 |

Sum of inner diameter and thickness must be ~2,200mm. Parts with external diameter larger than 1,900mm can only be supplied without heat treatment (upon consultation) and normalized. Parts with external diameter larger than 2,000mm can only be supplied with height about 200mm. |

Engineering Steel

| Product | ASTM | UNSA | INSI | Others |

| VM40 | ASMT A332 (4340) | G43400 | 4340 | SAE 4340/

AMS 6414 |

| F11 | ASTM A182

GRADE F11 (MOD.) |

K11597

K11572 |

ASME SA387

Gr. 11 |

|

| F22 | ASTM A182

GRADE F22 (MOD.) |

K21590 | ASME SA387

Gr. 22 |

|

| VB30 | ASTM A322 (8630)

ASTM A29 (8630)

|

G86300 | 8630 | SAE 8630 |

| VL30 | ASTM A322 (4130) | G41300 | 4130 | SAE 4130 |

| VL40 | ASTM A322 (4140)

ASTM A646 (4140) |

G41400 | 4140 | AMS 6349 |

| VM30 | ASTM A322 (4330)

ASTM A29 |

K23080 | 4330 | EN 30B / AMS 6411

|

Specialty Alloys

| Product | ASTM | UNSD | IN / Wnr. |

| VRC625 | ASTM B446 | UNS N06625 | DIN 17744

Wnr. 2.4856 |

| VATX750 | ASTM B637 | N07750 | Wnr. 2.4669 |

| VATX286A | ASTM A660 | Wnr. 1.4980 | |

| VAT718A | ASTM B637 | N07718 | Wnr. 2.4668 |

| VAT800HT | ASTM B408 | N08811 | Wnr. 1.4876

1.4959 |

| VRC400 | ASTM B164

B564 |

N04400W | Wnr. 2.4360 |

Precipitation Hardening Steels

| Product | ASTM | DIN / Wnr. | Others |

| V630 | ASTM A564

(630) 17-4 PH |

1.4542 | AMS 5643

AMS 5622 |

| N4534 | ASTM A564

(XM-13) PH 13-8 Mo |

1.4534 | AMS 5629 |

Duplex and Super Duplex Stainless Steels

| Product | ASTM | UNS | DIN / Wnr. |

| N4460 | ASTM A182

GR F50 / ASTM A276 |

UNS S32900 | DIN X3CrNiMoNbN

Wnr. 1.4460 |

| N4462 | ASTM A 182

Gr. F51 / ASTM A276 |

UNS S31803 | DIN 2CrNiMoN

Wnr. 1.4462 |

| VF53 | ASTM A182

Gr F53 / ASTM A276 |

UNS S32750 | DIN X2CrNiMoN25-7-4

Wnr. 1.4410 |

| N4501 | ASTM A182

Gr F55 / ASTM A276 |

UNS S32760 | DIN 2CrNiMoCuWN25-7-4

Wnr. 1.4501 |

| N4507 | ASTM A182

Gr F61 / ASTM A276 |

UNS S32550 | DIN X2CrNiMoCuN25-6-3

Wnr. 1.4507 |

Martensic Stainless Steels

| Product | ASTM | NS | AISI | DIN / Wnr. | Others |

| N4313 | ASMT A182

Gr F6NM |

S41500 | DIN X3CrNiMo13-4

Wnr. 1.4313 |

| VC140 | ASTM A276 (410)

ASTM A182 / Gr F6a |

S41o00 | 410 | DIN X12Cr13

Wnr. 1.4006 |

NBR 5601

SAE 51410

|

| VC150 | ASMT A276 (420) | S42000 | 420 | DIN X20Cr13

Wnr. 1.4021 |

NBR 5601

Type 420 |

| V416 | ASMT A582 (416) | S41600 | 416 | DIN X12CrS13

Wnr. 1.4005 |

NBR 5601

AMS 5610L Type II |

Maraging Steels

| Product | ASTMU | NS | AMSM | IL |

| VART250

(MARAGING 250) |

ASTM A579

GR 72 |

UNS K92890 | AMS 6512 | MIL-S-46850D |

| VART300

(MARAGING 300) |

ASTM A579

GR 73 |

UNS K93120 | AMS 6514 | MIL-S-46850D |

| VXM19 | ASTM A276/

ASTM A479 GR XM19 |

S20910 | AMS 6514 | MIL-S-46850D |

Austentic Stainless Steels

| Product | ASTM | UNS | AISI | DIN / Wnr. |

| V304UF | ASMT A182 / Gr F304

ASTM A276 |

S304003 | 04 | DIN X5CrNi18-10

Wnr. 1.4302 |

| V304XLUF | ASMT A182 / Gr F304L

ASTM A276 |

S30403 | 304L | DIN X2CrNi18-9

Wnr. 1.4307 |

| V316UF | ASMT A182 / Gr F316

ASTM A276 |

S316003 | 16 | DIN X5CrNiMo17-12-2

Wnr. 1.4401 |

| V316XLUF | ASMT A182 / Gr F316L

ASTM A276 |

S31600 | 316L | DIN X2CrNiMo17-12-2

Wnr. 1.4404 |

| V317L | ASMT A182 / Gr F317L

ASTM A276 |

S31703 | 317L | DIN X3CrNiMo18-12-3

Wnr. 1.4449 |

| V321 | ASMT A182 / Gr F321

ASTM A276 |

S321003 | 21 | DIN X5CrNiTi18-10

Wnr. 1.4541 |

| V347SI | ASTM A182 / Gr F347

ASTM A276 |

S347003 | 47 | DIN X5CrNiTi18-10

Wnr. 1.4543 |

Enpar

Enpar

Produkte

|

|

|

|

|

|

|

|

Services

|

|

|

|

|

|

|

|

Nickel Alloys

| Material Number | Alloy | UNS |

| 2.4068 | Nickel 201 | N02201 |

| 2.4360 | Alloy 400 | N04400 |

| 2.4375 | Alloy K500 | N05500 |

| 2.4602 | Alloy C22 | N06022 |

| 2.4605 | Alloy 59 | N06059 |

| 2.4610 | Alloy C-4 | N06455 |

| 2.4633 | Alloy 602 CA | N06025 |

| 2.4634 | Alloy 105 | N132021 |

| 2.4650 | Alloy C-263 | N07263 |

| 2.4660 | Alloy 20 | N08020 |

| 2.4663 | Alloy 617 | N06617 |

| 2.4665 | Alloy X | N06002 |

| 2.4668 | Alloy 718 | N07718 |

| 2.4669 | Alloy X-750 | N07750 |

| 2.4816 | Alloy 600 | N06600 |

| 2.4819 | Alloy C-276 | N10276 |

| 2.4851 | Alloy 601 | N06601 |

| 2.4856 | Alloy 625 | N06625 |

| 2.4858 | Alloy 825 | N08825 |

| 2.4878 | Alloy 101 | |

| 2.4951 / 2.4630 | Alloy 75 | N06075 |

| 2.4952 / 2.4631 | Alloy 80A | N07080 |

| 2.4964 | Alloy L-605 | R30605 |

| 2.4969 / 2.4632 | Alloy 90 | N07090 |

| 2.4973 | Alloy R-41 | N07041 |

| 2.4975 / 2.4662 | Alloy 901 | N09901 |

| Alloy 725 | N07225 | |

| 2.4852 | Alloy 925 | N09925 |

Titanium and Titanium Alloys

| Material Number | Alloy | UNS |

| 3.7025 / 3.7024 | Ti Grade 1 | R50250 |

| 3.7025 / 3.7024 | Ti Grade 2 | R50400 |

| 3.7055 | Ti Grade 3 | R50550 |

| 3.7065 / 3.7064 | Ti Grade 4 | R50700 |

| 3.7105 | Ti Grade 12 | R53400 |

| 3.7145 / 3.7144 | Ti-6-2-4-2 | R54620 |

| 3.7165 / 3.7164 | Ti Grade 5 | R56400 |

| 3.7175 / 3.7174 | Ti-6-6-2 | R56620 |

| 3.7185 / 3.7184 | Ti-4-4-2 | |

| 3.7195 / 3.7194 | Ti Grade 9 | R56320 |

| 3.7235 | Ti Grade 7 | R52400 |

Special Steel

| Material Number | Alloy | UNS |

| 1.3912 | Alloy 36 | K93600 |

| 1.3917 | Alloy 42 | K94100 |

| 1.3964 | Alloys 50 | S20910 |

| 1.3974 | ||

| 1.3981 | Alloy K | K94610 |

| 1.4313 | F6NM | S41500 |

| 1.4429 ESU | 316LN ESR | S31653 |

| 1.4529 | Alloy 926 | N08904 |

| 1.4534 | PH 13-8Mo | S17400 |

| 1.4539 | Alloy 904L | N08904 |

| 1.4542 / 1.4548 | 17-4 PH | S17400 |

| 1.4545 | 15-5 PH | S15500 |

| 1.4550 / 1.4546 | Alloy 347 | S34700 |

| 1.4562 | Alloy 31 | N08031 |

| 1.4568 | 17-7 PH | S17700 |

| 1.4876 | Alloy 800 | N08810 |

| 1.4939 | Jethete | S64152 |

| 1.4958 | Alloy 800H | N08810 |

| 1.4959 | Alloy 800HT | N08811 |

| 1.4980 / 1.4944 | A286 | S66286 |

| 1.4986 | ||

| 1.6358 / 1.6354 | Maraging 300 | K93120 |

Other

| Material Number | Alloy | UNS |

| Zr 702 | R60702 | |

| Zr 705 | R60705 | |

| Molybdenum | ||

| Tantulum | ||

| Tungsten |

voestalpine Specialty Metals

voestalpine Specialty Metals

Services

|

|

|

|

|

|

|

|

|

|

|

Nickel Alloys

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

| L359 | Alloy 59 | N06059 |

x |

||||||

| Monel 400 | Alloy 400 | N04400 | x |

|

|||||

| Monel K500 | Alloy K500 | N05500 | x |

|

|||||

| L331/L625 | Alloy 625 | N06625 | x |

x |

x | x | x | x | x |

| L718 | Alloy 718 AMS | N07718 | x |

x |

x | x | x | x | x |

| L718API | Alloy 718 API | N07718 | x |

x |

x | x | x | x | |

| L725 | Alloy 725 | N07725 | x |

x |

x | x | |||

| L314 | Alloy 825 | N08825 | x |

x |

x | x | x | x | |

| L090 | Alloy 90 | N07090 | x |

x |

x | ||||

| L901 | Alloy 901 | N09901 | x |

x |

x | x | |||

| L925 | Alloy 925 | N09925 | x |

x |

x | x | |||

| L022 | Alloy C22 | N06022 | x |

x |

x | ||||

| L276 | Alloy C276 | N10276 | x |

x |

x | ||||

| L004 | Alloy C4 | N06455 | x |

x |

x | ||||

| L003 | Alloy G3 | N06985 |

x |

||||||

| L750 | Alloy X750 | N07750 |

x |

||||||

| L303 | Waspaloy | N07001 | x |

x |

x |

Ferritic, Martensitic & PH Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

| N400 | F6NM | S41500 | x |

x |

x | x | |||

| N404 | DIN 1.4418 | SS2387 |

x |

||||||

| N700 | 17-4 PH | S17400 | x |

x |

x | x | |||

| N701 | 15-5 PH | S15500 | x |

x |

x | ||||

| 13CR (420M) | S42000 | x |

|

||||||

| Super 13CR | S41427 | x |

|

Duplex & Super Duplex Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

| A903 | F51 Duplex | S31803 | x |

x |

x | x | x | x | |

| A913 | F53 Dupley | S32750 |

|

x | x | x | |||

| A911SA | F55 Duplex | S32760 | x |

x |

x | x | x | x |

Austenitic Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

| A200 | 316/316 L | S31600/S31603 | x |

|

|||||

| A965SA | F44 6Mo | S31254 | x |

x |

x | x | |||

| T200 | A286 | S66286 | x |

x |

x | ||||

| P511 | Nitronic 50 | S20910 | x |

x |

x | ||||

| P513 | Nitronic 60 | S21800 | x |

x |

x |

Engineering Steels

| Product | Market Grade | UNS | Bar | Billet | Wire | Sheet | Plate | Forgings | AM Powder |

| F22 | K21590 | x |

x |

x | |||||

| 4130 | G41300 | x |

x |

x | |||||

| 4140 | G41300 | x |

x |

x | |||||

| 4145 | G41300 | x |

x |

x | |||||

| 4330V Mod. | K23080 | x |

x |

x | |||||

| 8630 Mod. | G86300 | x |

x |

x | |||||

| 9CR/1MO | K90941 | x |

x |

x | |||||

| L314 | 4330V Mod. | K23080 | x |

x |

x | ||||

| L090 | Alloy 90 | N07090 | x |

x |

x | ||||

| L925 | Alloy 925 | N09925 | x |

x |

x | x | |||

| L022 | Alloy C22 | N06022 | x |

x |

x | ||||

| L276 | Alloy C276 | N10276 | x |

x |

x | ||||

| L004 | Alloy C4 | N06455 | x |

x |

x | ||||

| L003 | Alloy G3 | N06985 |

x |

Formen

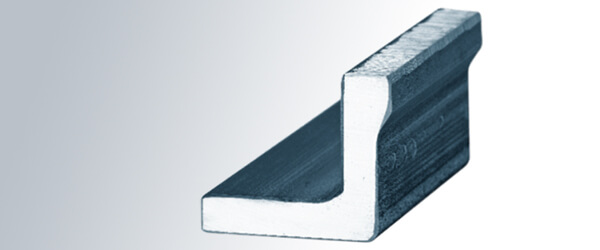

Wir bieten unsere Materialien in einer breiten Palette von Formen in verschiedenen Abmessungen an.

Services

Wir verfügen über ein eigenes Vertriebs- und Servicenetz an rund 140 Standorten in allen Industrieregionen der Welt. Wie wichtig dieser Aspekt ist, zeigt auch die Tatsache, dass rund 40 % aller Mitarbeiter der Sparte im Vertrieb und Service tätig sind.

Additive Fertigung

Die additive Fertigung (AF), auch bekannt als “3D-Druck”, ermöglicht die Produktion mit kürzeren Vorlaufzeiten, bei geringerem Gewicht und für Formen, die bisher nicht machbar waren.

PVD & CVD Beschichtung

Mit der Übernahme von Eifeler sind wir einer der führenden Anbieter von PVD- (und CVD-) Beschichtungen. Entdecken Sie hier unsere breite Palette an Beschichtungssystemen.

Wärmebehandlung

Wir bieten über unser weltweites Vertriebsnetz eine breite Palette von Wärmebehandlungen an. Dies ermöglicht es uns, unsere Produkte für Ihre spezifischen Anwendungen zu optimieren.

Bearbeitungs- und Schneidedienstleistungen

Unser Ziel ist es, die bestmögliche Verfügbarkeit und kurze Lieferzeiten zu gewährleisten. Dies erreichen wir durch Bearbeitungsdienstleistungen, die wir über unser weltweites Vertriebsnetz anbieten.

Lager

Mit unserem Angebot an lagertechnischen Lösungen erfüllen wir höchste Kundenanforderungen, decken die gesamte Wertschöpfungskette ab und garantieren beste Qualitätsstandards.