Best performance for complex operations.

LOCCAM® was developed to optimize yield, increase part quality and output, and ensure precision and quality in your operation. A savings in raw material of up to 8% is possible.

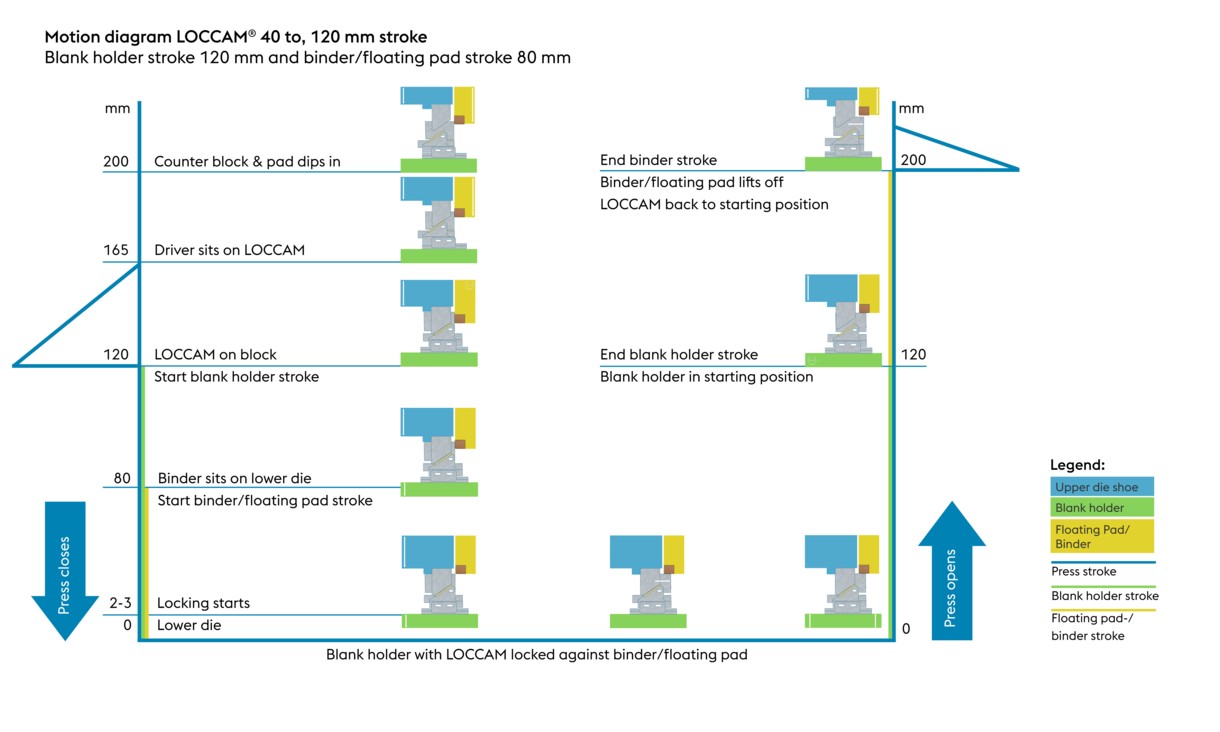

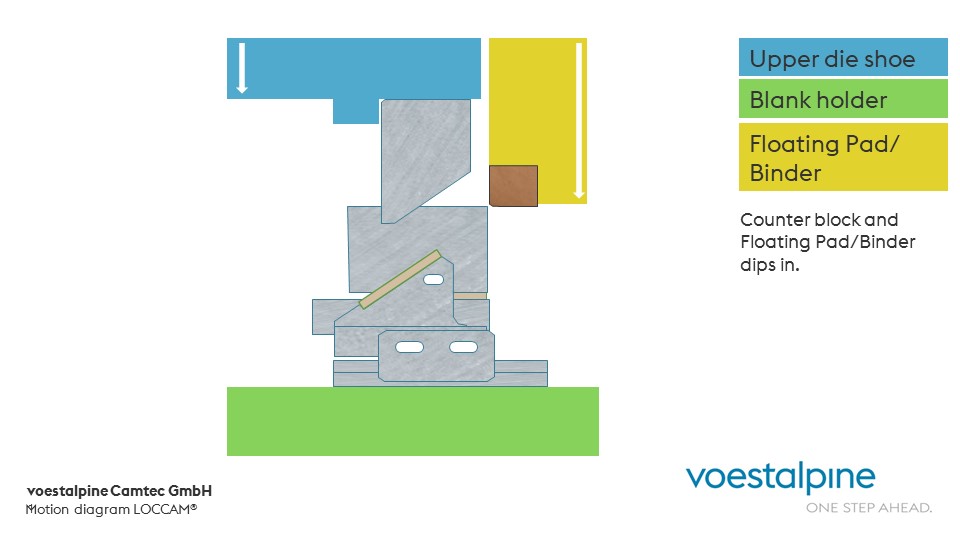

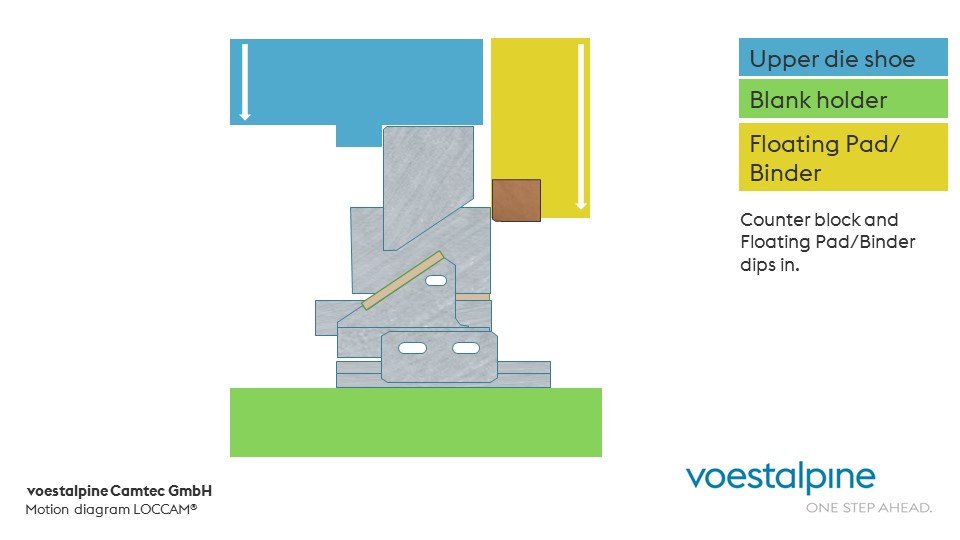

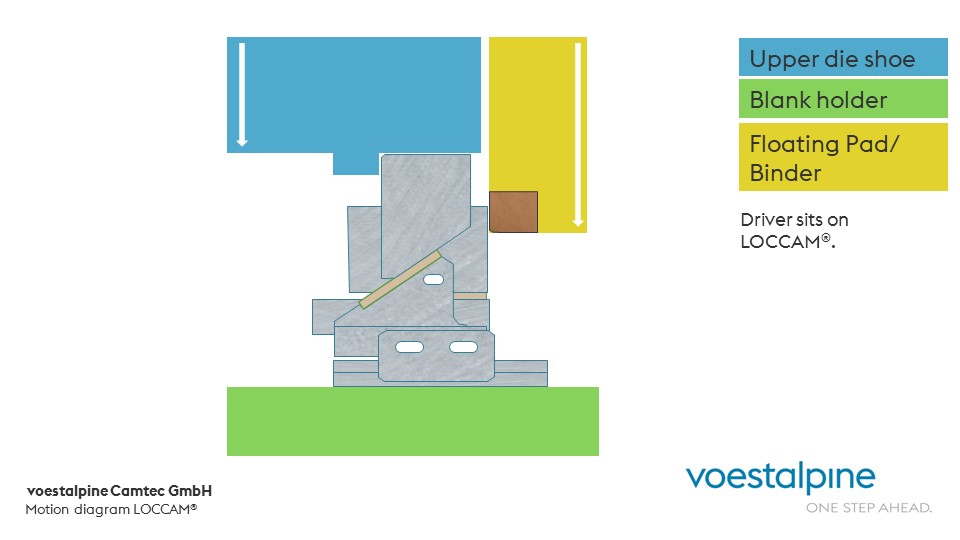

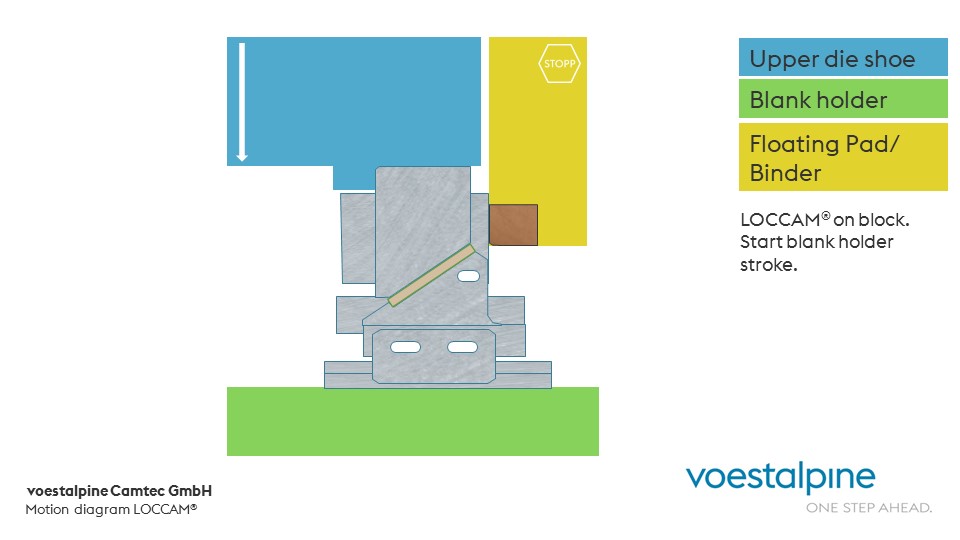

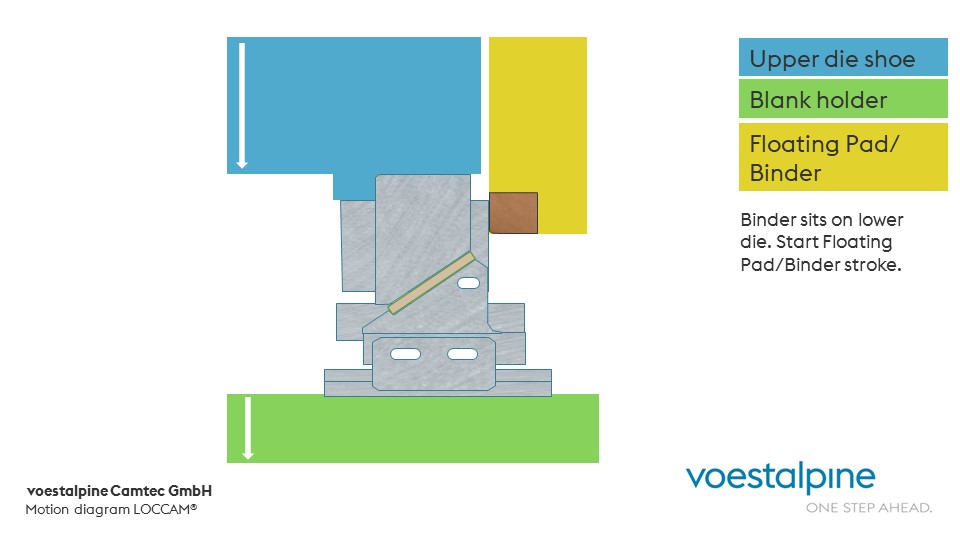

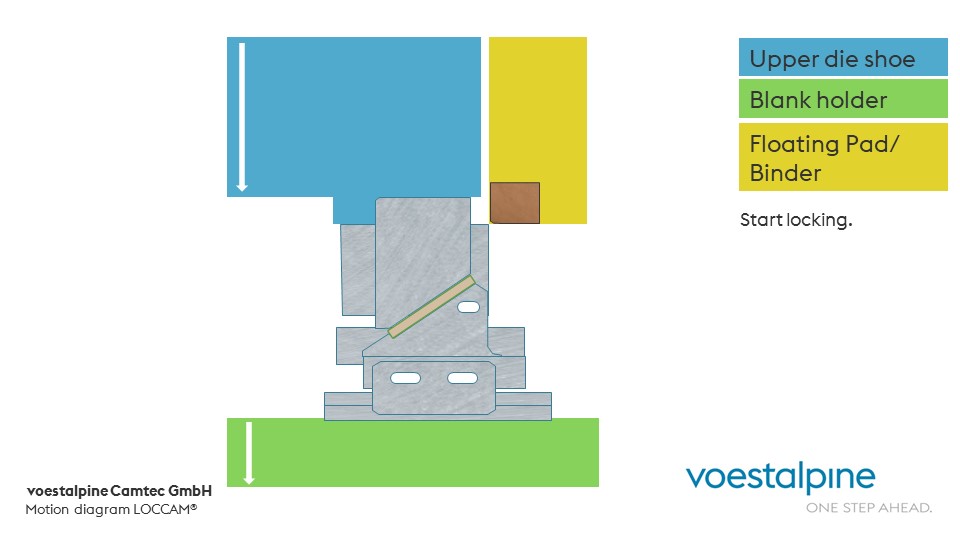

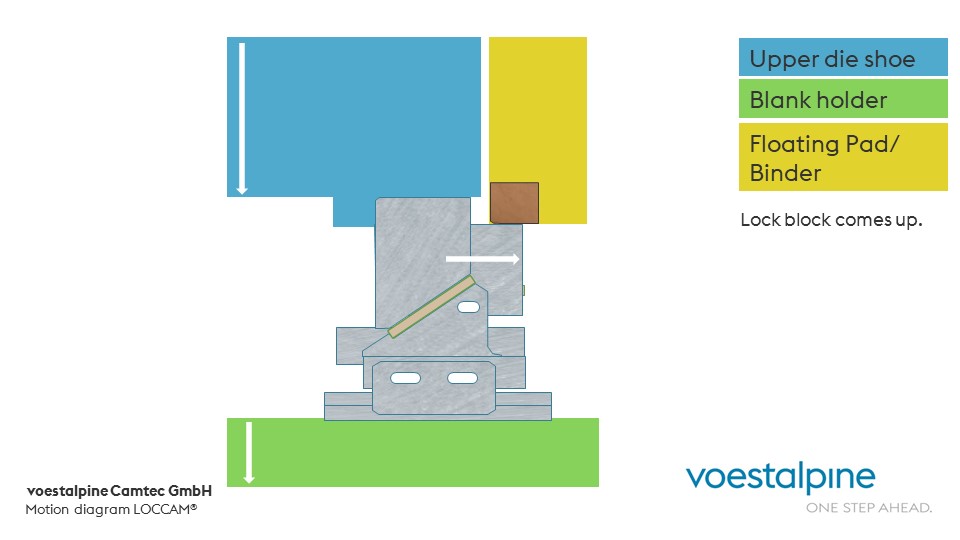

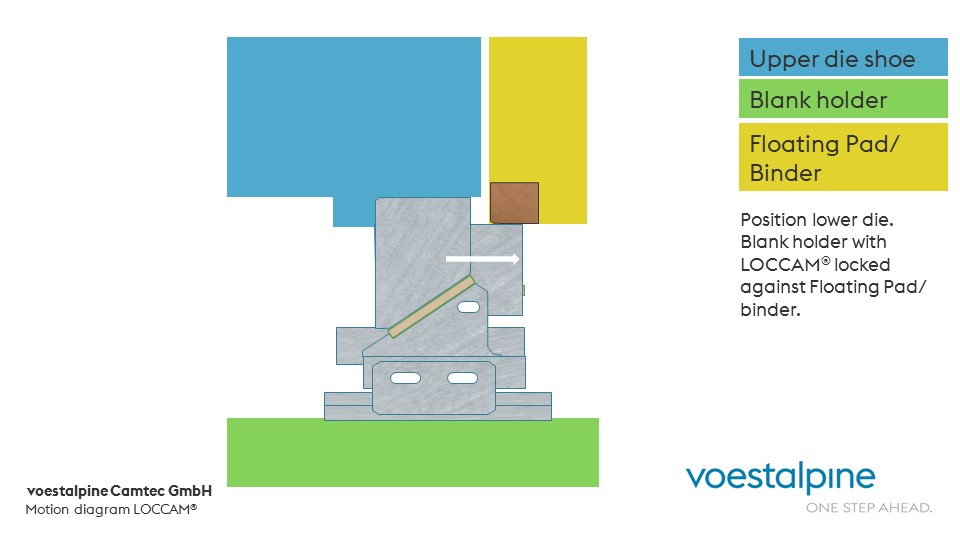

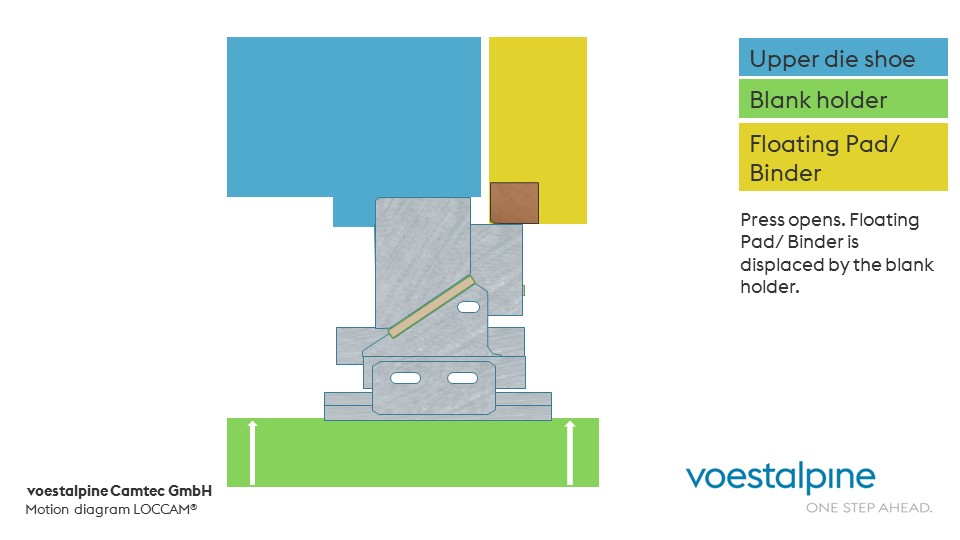

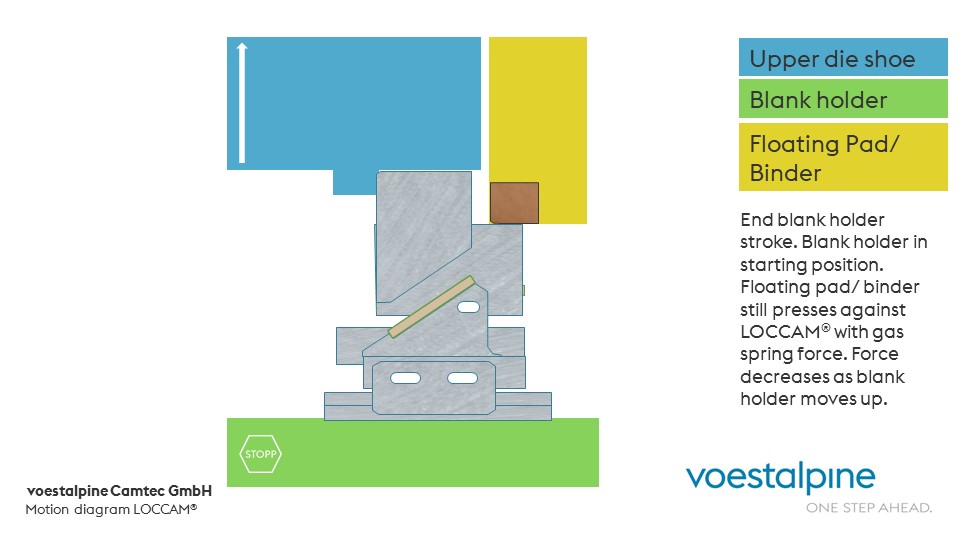

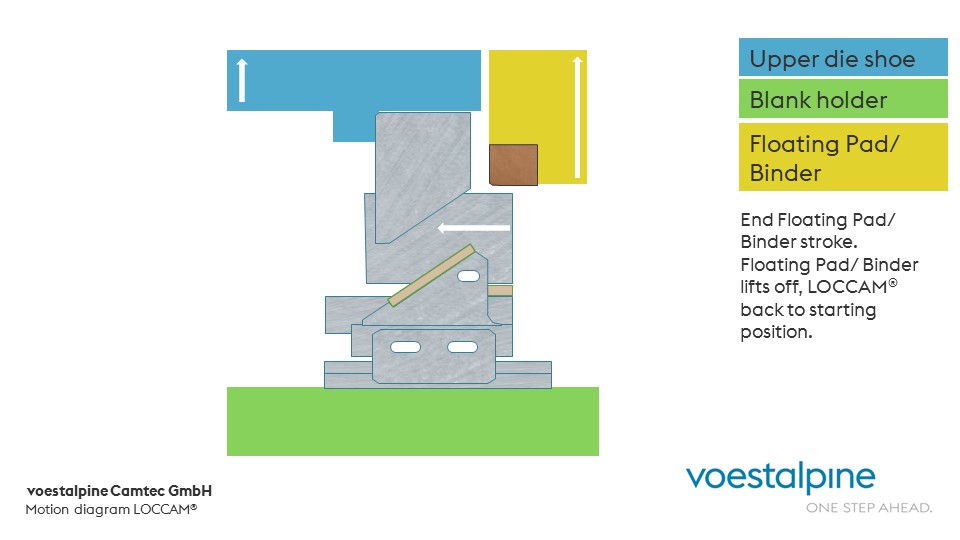

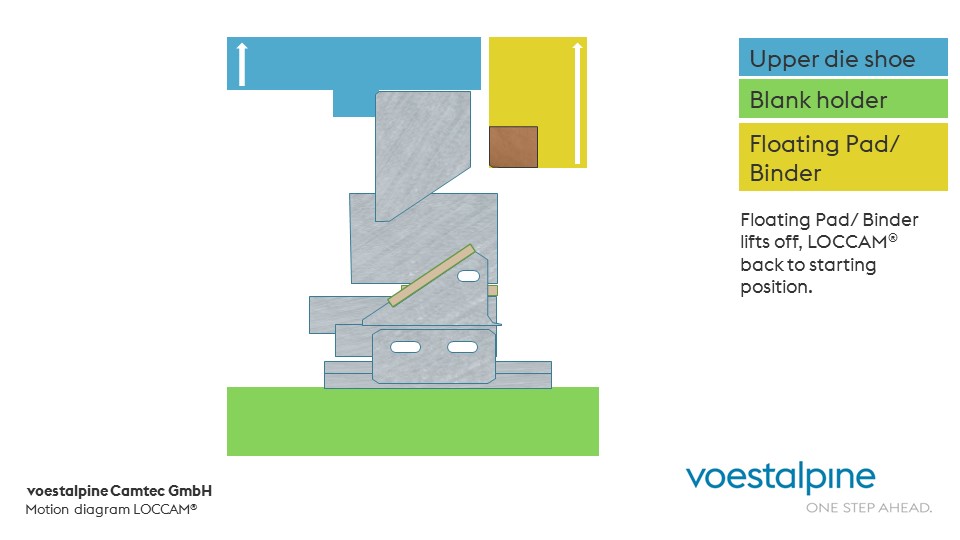

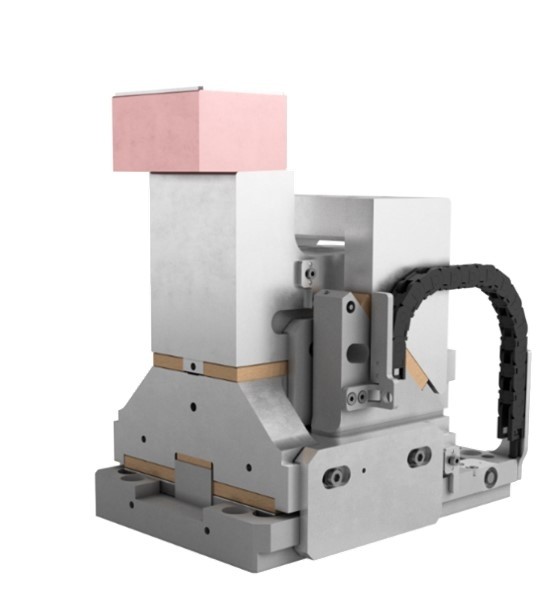

In (deep) drawing operations, LOCCAM® mechanically maintains the distance between the blank holder and the flexible binder/floating pad, which helps to avoid deformations when opening and ejecting the component. With its compact size and high load, LOCCAM® is a reliable system that replaces controlled gas springs and other applications.

The most innovative locking system

- Quality improvement and cost reduction leads to better part quality and increases the part rate

- Innovative system which replaces controlled gas springs, pneumatic or hydraulic cylinders or other applications

- Higher output: Increased cycle times compared to other systems

- Sensor technology for end position detection

- Compact size and high load

- Flexibility: LOCCAM® can easily be adapted to draw depth of main pad by machining of mainpad and blank holder (kinematic check necessary)

- High-quality materials such as tempered steel, high-resistant bronze alloy, Duplex-Variantic coating upon request

- Floating bearing incl. 2° lead-in angle

Dimensions

- Available length: 200 mm, 260 mm

- Available vertical stroke: 60 mm, 120 mm

- Max. force per cam: 20 tons, 40 tons

Motion diagram