Higher, faster, lighter: aerospace and the pursuit of lightness

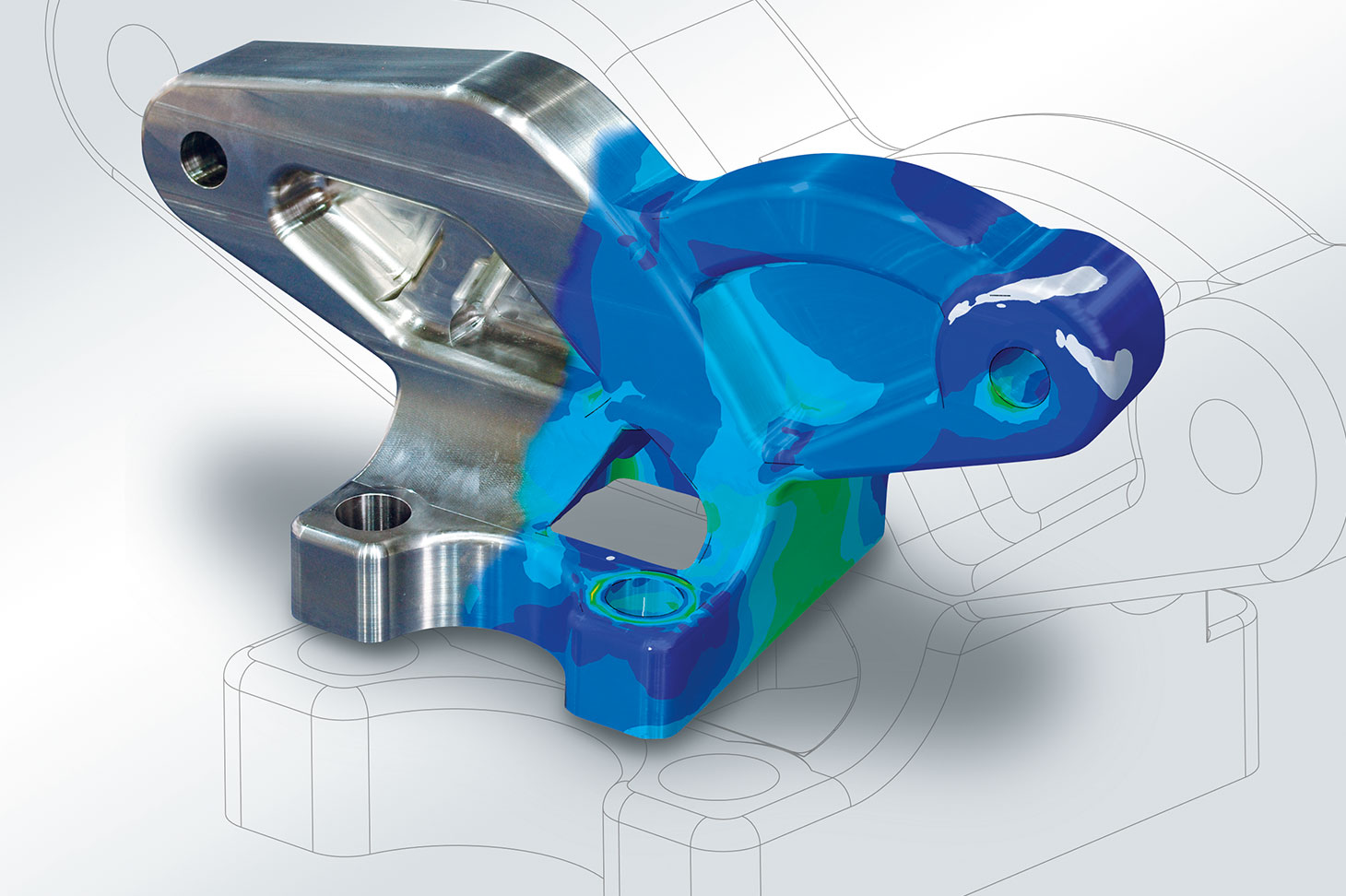

When building aircraft, every gram counts, because weight-reduced parts made of high-performance materials not only make aviation safer, they make it more economical and sustainable. The lightweight construction philosophy at voestalpine ensures maximum quality combined with the lowest possible weight.

- 12 Jul, 2022

- 4