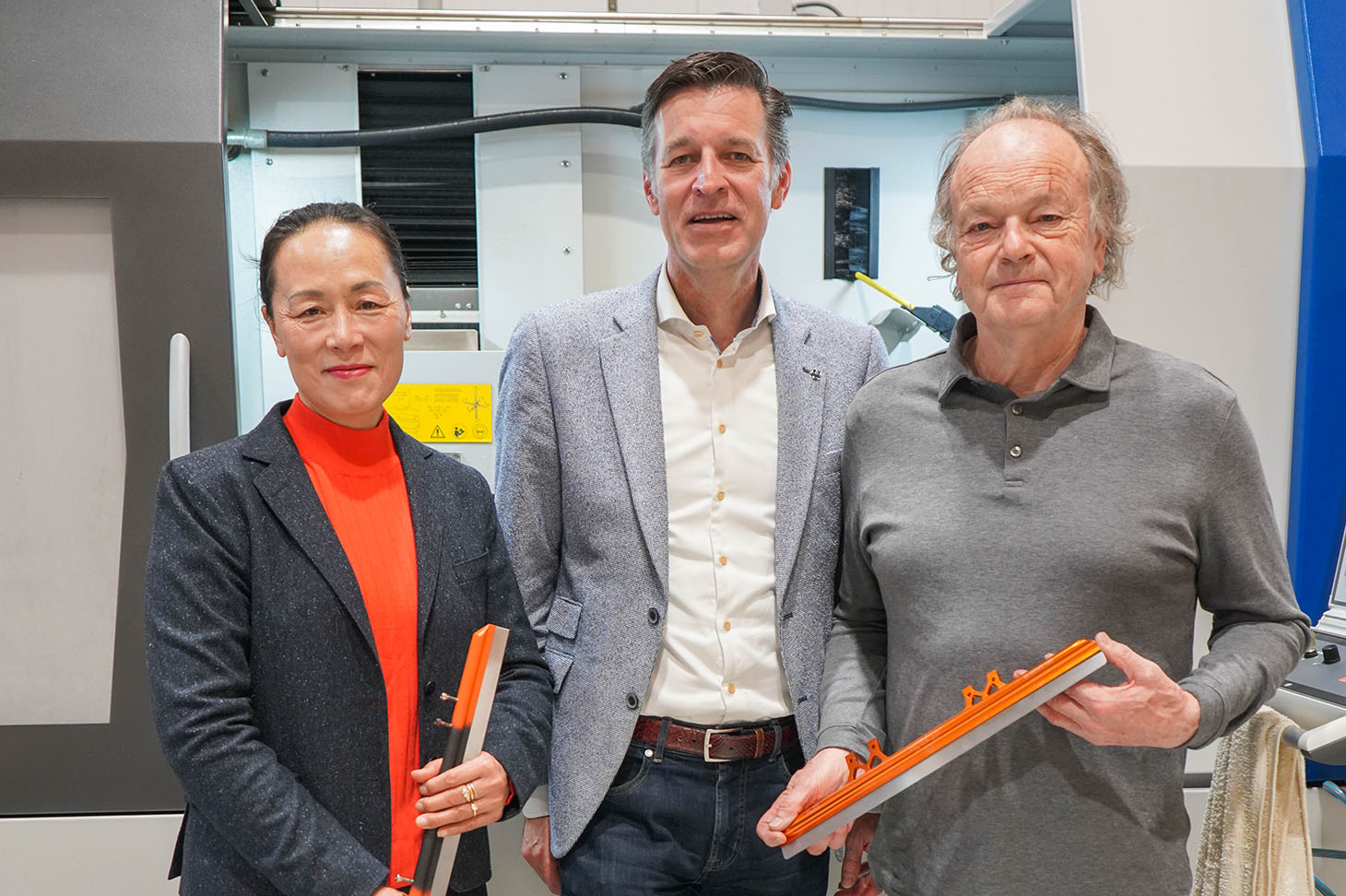

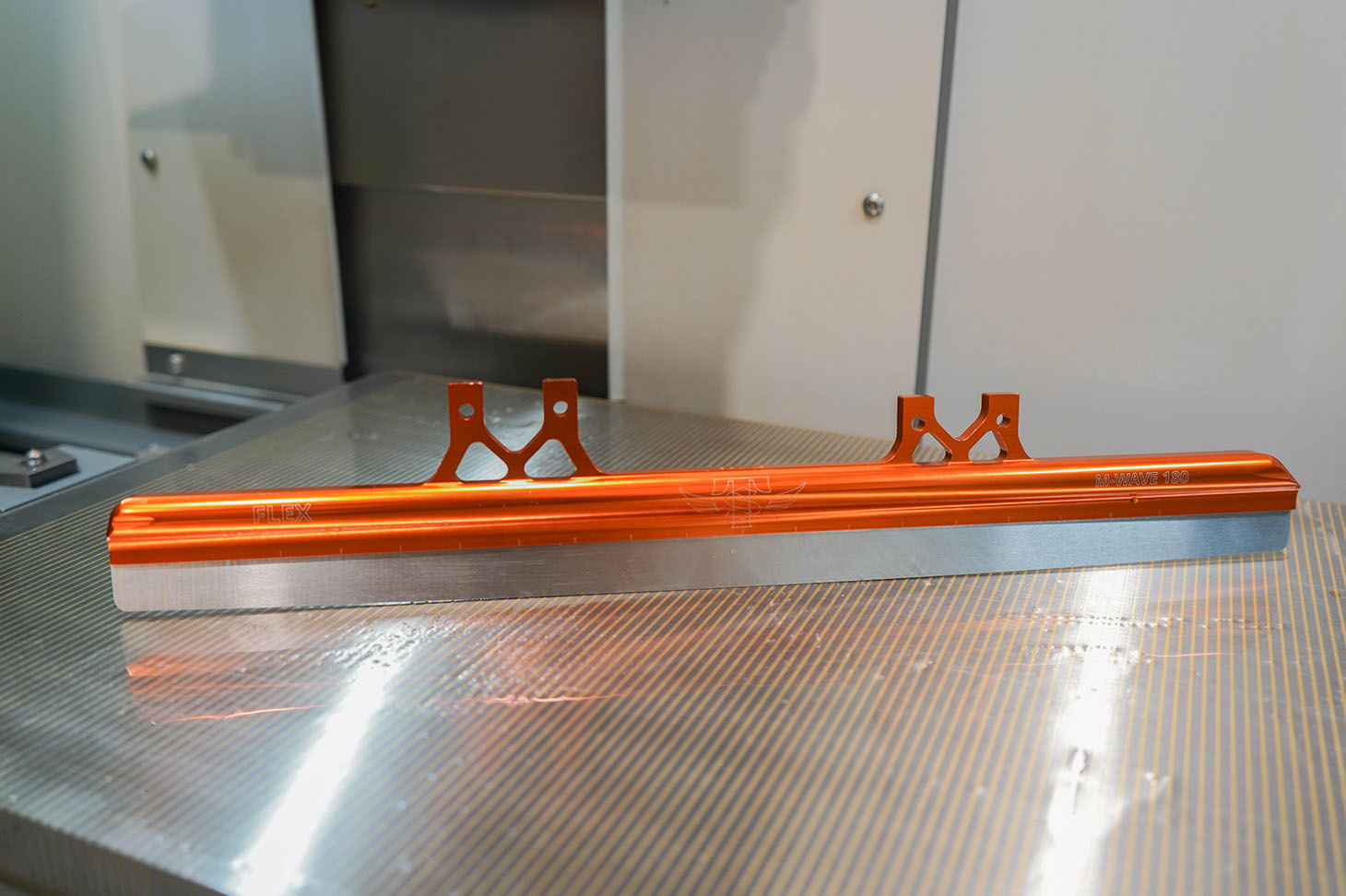

voestalpine on hot ice

The speed skating world championships once again offered our high-speed steel a widely recognized stage. Things heated up when BÖHLER steel and voestalpine Precision Strip’s bimetal strip demonstrated their world-class performance in Heerenveen, the Netherlands.

- 10 Mar, 2023

- 3