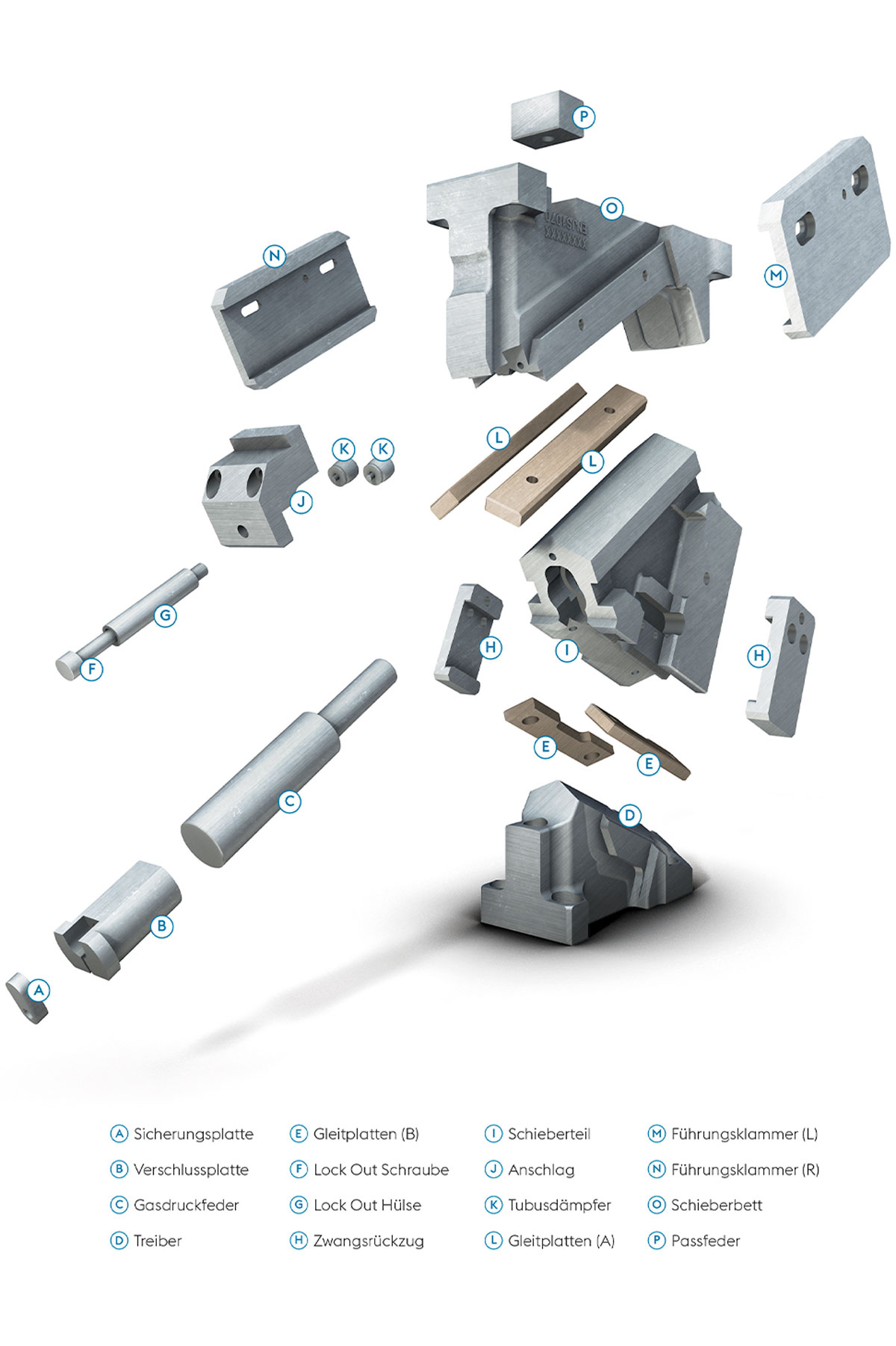

voestalpine Camtec extends the Life of Cam Units

Longer useful lives and optimized reliability: voestalpine Camtec GmbH successfully works to ensure that its premium products are used with care. This voestalpine Group company has carried out research projects on the longevity of its cam units in collaboration with its customers.

- 15 Jun, 2022

- 2