Competence center for cold stamping

voestalpine Automotive Components Dettingen GmbH & Co. KG develops and produces ready-to-install stamped and formed parts, complex assemblies as well as safety and impact protection components for notable car manufacturers. With about 700 employees and expertise unique to the industry, Dettingen is the competence center of the voestalpine Automotive Components Cold Stamping Group. As the internationally leading technology center, Dettingen is the perfect partner from development to delivery.

Competences

We use state-of-the-art progressive and transfer technologies and innovative production processes to produce more than 2 million parts annually. From development to prototype construction throughout the project and up to series production and logistics, we offer our customers a coordinated production cycle.

- 300 t to 1,600 t pressing capacity

- Cold- and hot-formed structural parts and assemblies

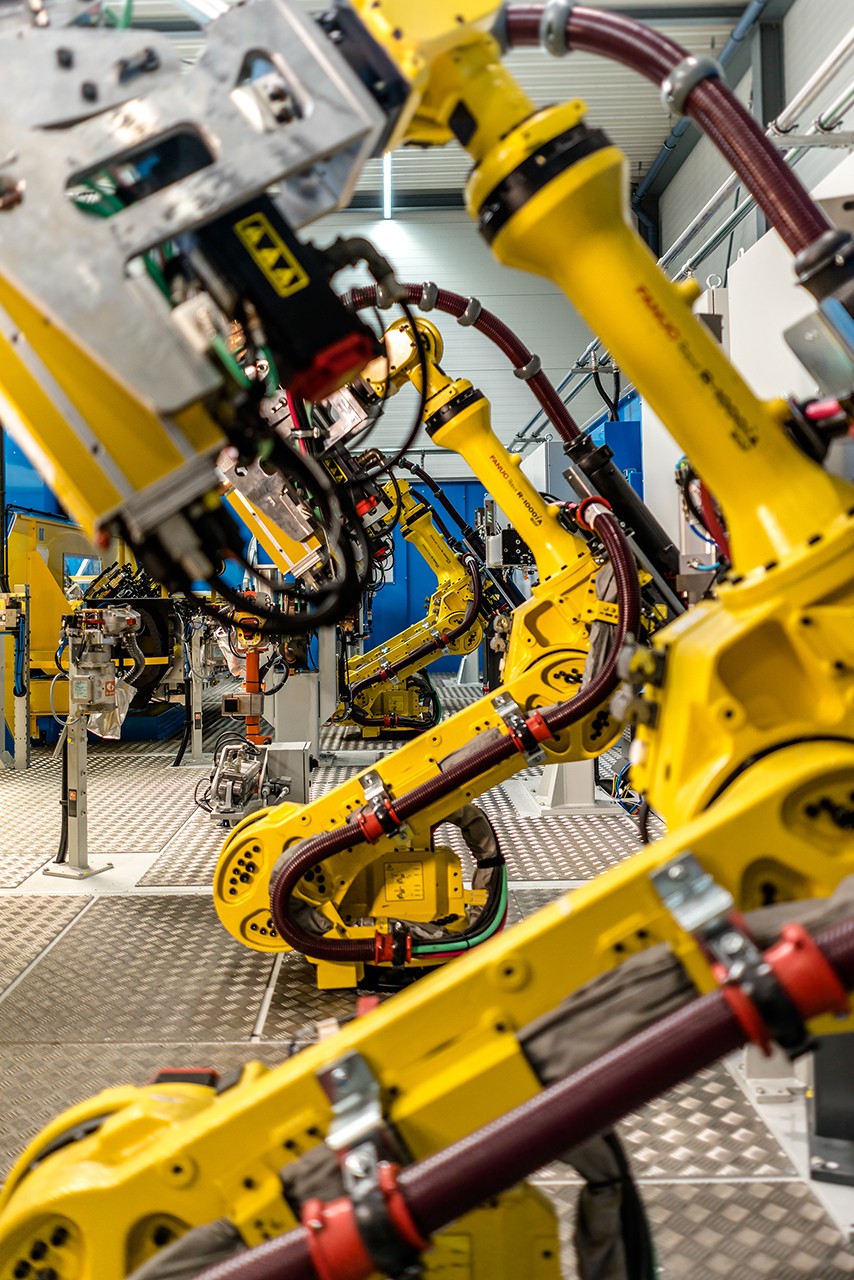

- Multiple automatic welding and assembly centers with joining technologies

Spot welding

MIG/MAG welding

Bolt welding

Nut welding

Riveting processes

Plastic injection

Assembly work areas

- Range of materials

Max. sheet thickness: 8 mm from the coil

Max. coil width: 1.6 m

Max. table length: 6 m

Max. table width: 2.5 m