Additive Manufacturing

THINK BEYOND THE LIMITS OF MANUFACTURING

Additive Manufacturing (AM), also known as “3D printing”, is not simply a new way of producing. It’s a new way of thinking. There are no borders when digitally designing and executing a final product – layer by layer.

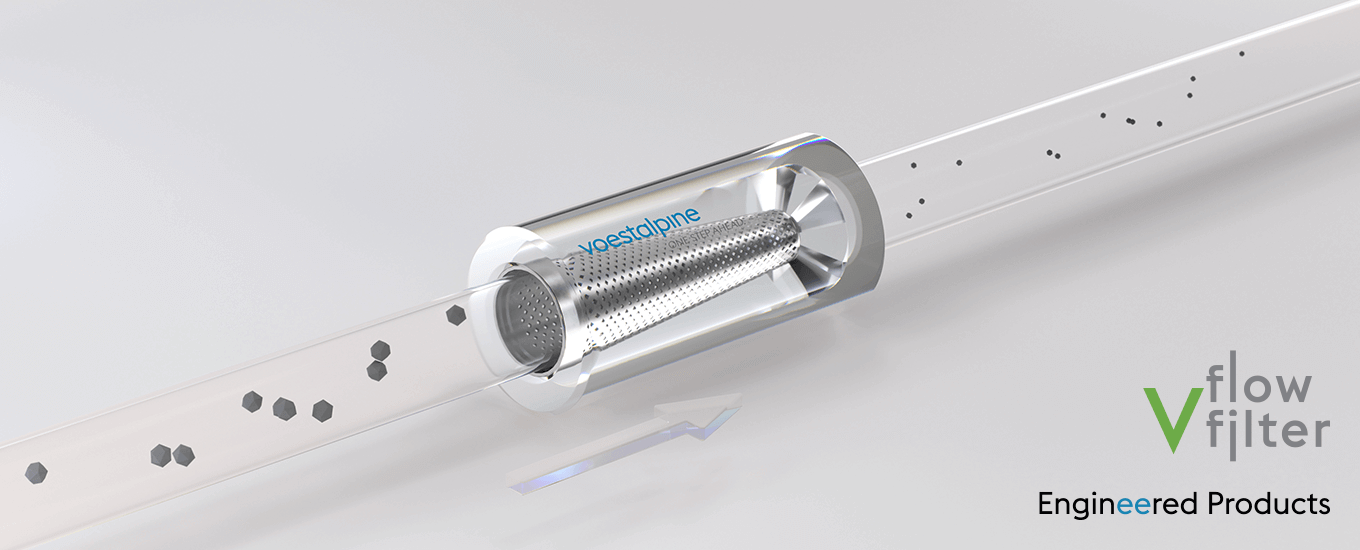

AM enables production with shorter lead times, at a lower weight, and of shapes that were not previously feasible.

After being digitally designed as a 3D-CAD model, even the most complex of structures can be “printed” with metal powder which has been specifically designed to meet the requirements of your application.

FROM CONCEPT TO COMPONENT

As a global steel and technology leader, we drive innovation and development based on lengthy experience around materials and processing. Starting from the alloy development and metal powder production, to design, manufacturing and post-processing, we offer end-to-end tailormade solutions from concept to component.

Metal Powder

Parameter Development

Design/Simulation

Additive Manufacturing

Heat Treatment

Machining

PVD Coating

Inspection/Testing

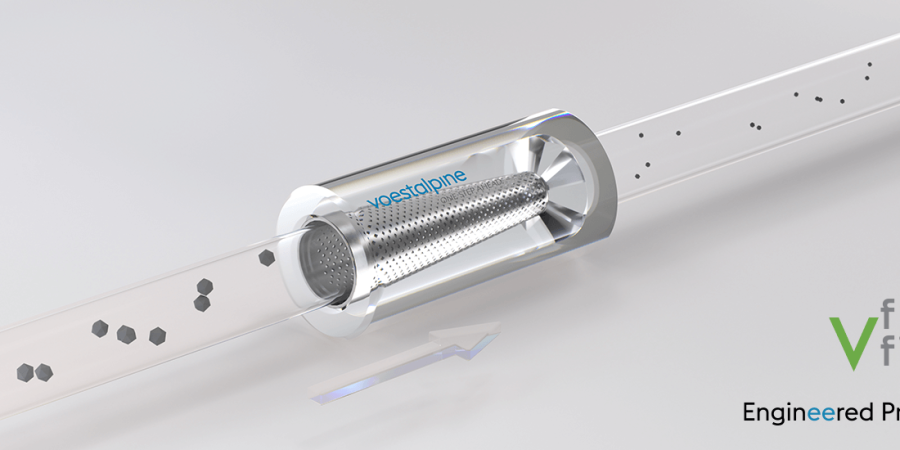

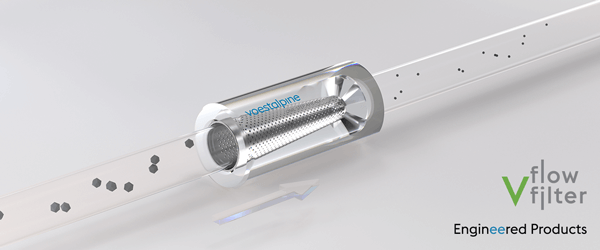

APPLICATIONS

While AM offers a nearly endless range of possibilities, there are certain areas of excellence that voestalpine has a special focus on.

PRODUCTS

For decades we have been recognized as a global leader in the manufacture and the supply of tool steel, as a result we understand the challenges that our customers face. Customer intimacy and technical understanding is a major factor when developing successful solutions with our partners.