Forming limit curves next level by voestalpine

Precisely what engineers need!

How far can the steel in question be formed? When will it fail? Forming limit curves (FLCs) provide the answer. voestalpine has further developed the existing model to determine FLCs based on tensile test parameters. With less effort, even more precise FLCs can now be created, and data for newly developed steel grades can be made available to customers more quickly.

Data on new steels

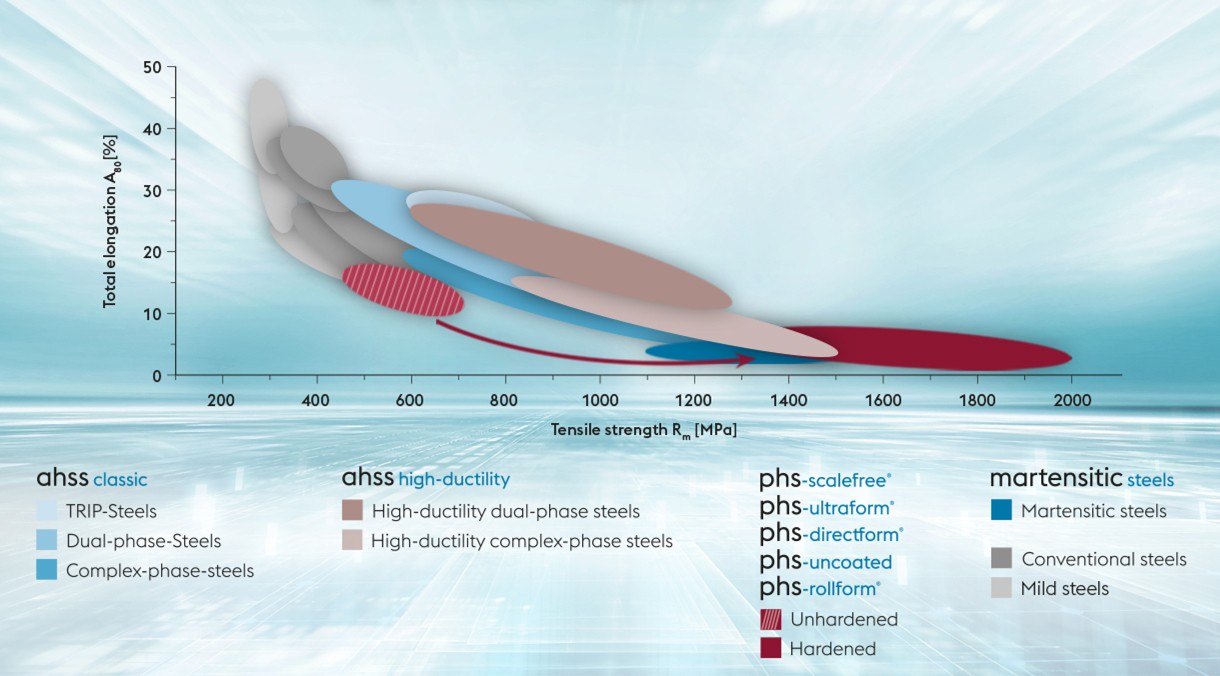

High-strength steels with tensile strengths of 1000 MPa and higher have been developed in recent years. Innovative steels from voestalpine expand the possibilities of lightweight automotive design. These include new high-ductility dual-phase and complex-phase steels or martensitic steels that close the strength gap with press-hardening steels.

Data assessment

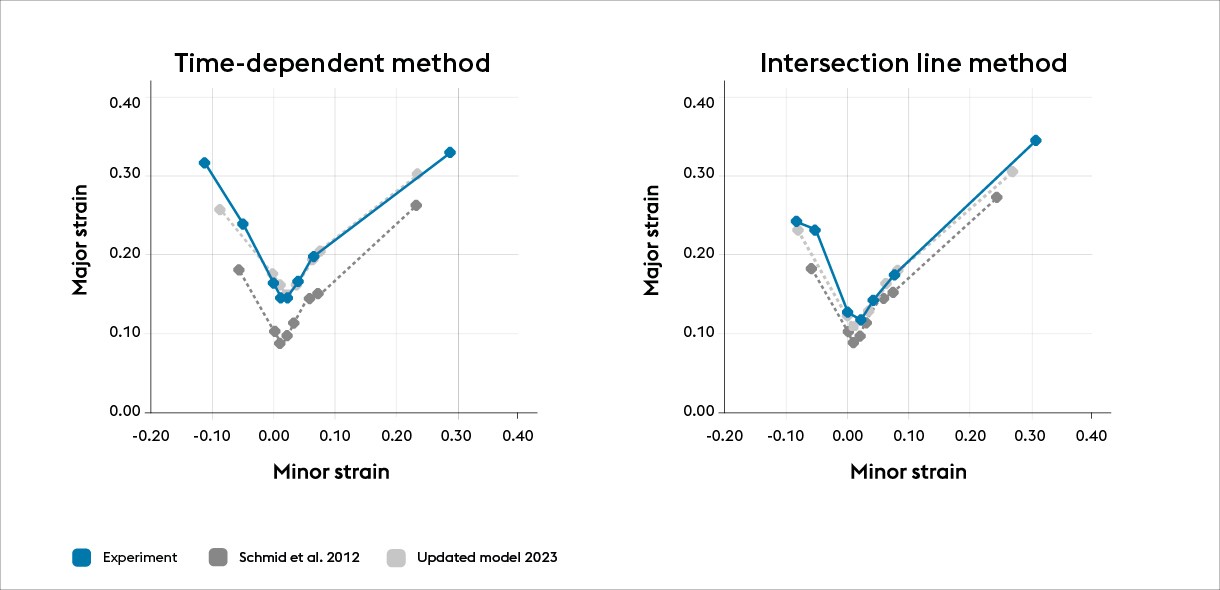

FLCs can be used to determine the failure limits of steels and to compare their levels of formability. They are used, for example, in feasibility analyses, forming simulations or tool design when deep-drawn components are required. The assessment of experimental data from samples that have been brought to failure and metrologically evaluated is time-consuming and expensive. Since 2012 voestalpine has implemented a linear regression model (Schmid et al. 2012) that predicts principal and secondary strain for each FLC sample geometry and analyzes the effects of sheet thickness and material properties. For this model, a total of 330 FLCs were used from steel grades available at the time. Now, 10 years later, the voestalpine database includes 770 FLCs, determined according to the intersection line method, and 250 FLCs, worked out according to the time-dependent method, which describes the increased forming potential of modern high-ductility steel grades in more detail.

Update available

The update utilizes various subsets of parameters from available material test data as predictor variables, including sheet thickness, yield strength, tensile strength, uniform elongation and total elongation. The FLCs of the advanced model were compared to a comprehensive set of experimentally determined FLCs. The evaluation showed that the updated model describes the experimental FLCs at a sufficiently high level of precision based only on the tensile test data. The update will be presented at the 14th European LS-DYNA Conference 2023 in Baden-Baden, Germany. Please find more detailed information in our Technical Report.

High-precision benefits

- More accurate models for a robust process design

- Easy and fast identification of the forming potential of new steel grades

- More cost-effective determination of FLCs

- Always up to date: The model can be easily updated as the experimental FLC database expands

- voestalpine provides material data on current cold-rolled and hot-rolled products that are implemented in the material databases of solver providers (AutoForm, COPRA FEA RF, LS-Dyna, PAM-Stamp, Stampack)