Galvanized hot forming steels for the production of press-hardened components using the indirect process

phs-ultraform® combines the benefits of press-hardened components with the high-quality corrosion resistance of galvanized steel strip. Hot-dip galvanized boron steel (22MnB5) further developed by voestalpine and the optimized indirect hot forming process set standards in automotive lightweight design with respect to freedom of design, dimensional accuracy and process reliability.

| EN 10338 and/or EN 10346 | VDA 239-500 | voestalpine special grades |

| - | CR1500T-MB-IS | phs-ultraform 1500 |

| - | CR500T-LA-IS | phs-ultraform 490 |

Carbon footprint greentec steel product

| greentec steel product | Maximum carbon footprint [kg CO2e/kg steel] 1) |

| Hot-dip galvanized steel strip | 2.30 |

1) The carbon footprint is calculated pursuant to worldsteel CML 2001-2016 (system expansion) on a cradle-to-gate basis.

All products, dimensions and steel grades listed in each voestalpine supply range are available as greentec steel.

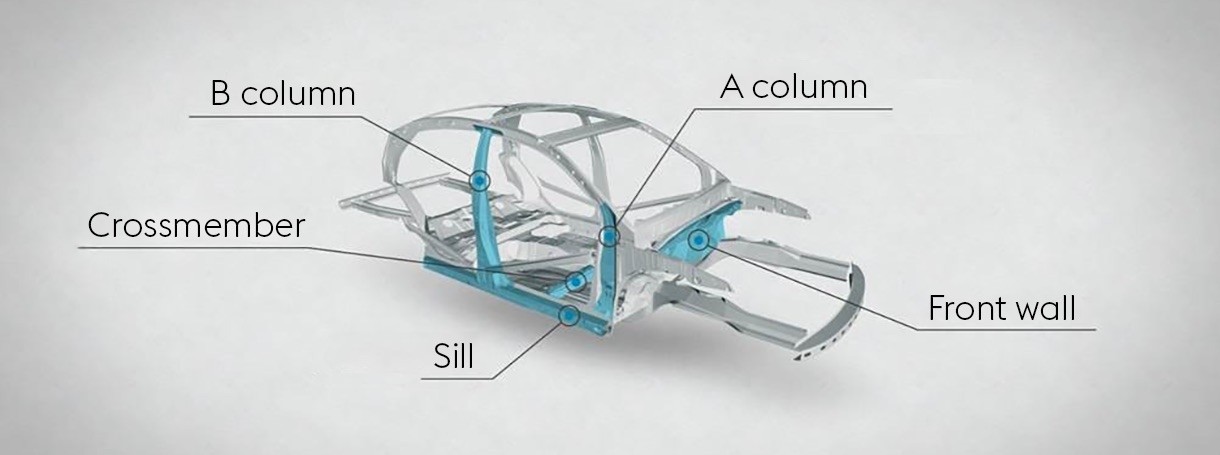

Optimal for large body and structural components

phs-ultraform® is especially recommended for large body and structural components and high-volume production. Safety and crash-relevant body and structural components with particularly complex component geometries are economically feasible.

Advantages of phs-ultraform® in detail:

- Excellent cathodic corrosion protection

- Press-hardening steel, perfect for lightweight automotive design

- Large components possible

- Complex components possible, even as tailored-property parts

- Best crash performance of press-hardened steel components

- Strengths ranging up to 1,500 MPa

- High dimensional accuracy and uniform strength distribution

- Minimum tool wear, even with high unit numbers

- Very good processability and coatability

- Standard transport corrosion protection

Process reliability and economic feasibility

The indirect forming process optimized by voestalpine has proven itself worldwide in automotive serial production. Blanks made of phs-ultraform® are formed to their final geometry by classic cold forming, finally trimmed and subsequently heated to approximately 900 °C. The hot components are positioned in a cooled tool for hardening and finalization of the component geometry (form hardening).

Overview video at the click of your mouse: