+46-563-170 00

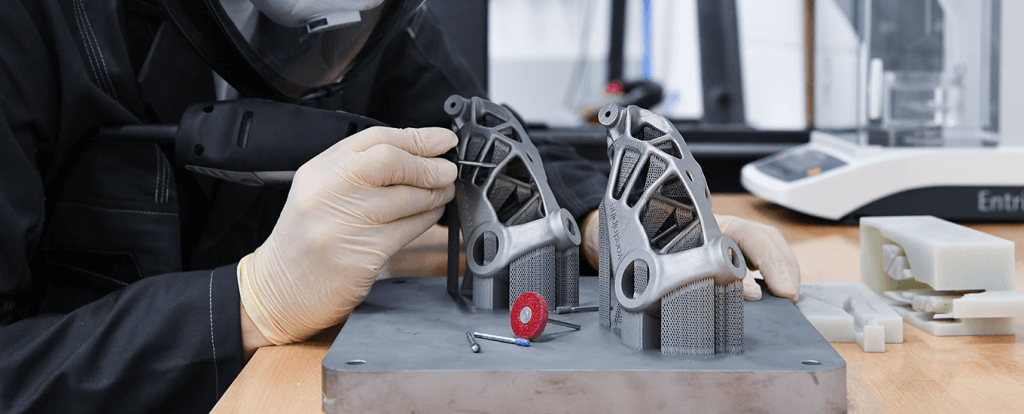

Customers benefit from our leading competence throughout the value chain, which ranges from powder development to the delivery of finished products. Starting with three-dimensional CAD data, AM enables the production of even the most complex shapes. We offer all of the current available AM technologies in our additive manufacturing centers in Singapore, Düsseldorf, Houston, Canada and Taiwan.