Cutting element for a bimetal saw chain

The lifetime of the cutting edge and therefore of saw chains until the next sharpening and inspection cycle can be significantly increased by using cutting elements in motorized chainsaws made of a laser-welded composite bimetal material. Hardness values of up to 750 HV and tensile strengths of up to 2,500 MPa can be achieved by using quenched and tempered high-speed steel. This makes it possible to use the saw for special purposes such as in emergencies by fire and rescue or for demolition work.

A global first: Bimetal saw chains with the highest possible resistance

Patent: WO2020239925

The invention on hand concerns the cutting element for a saw chain and a saw chain equipped with such types of cutting elements for motorized chainsaws.

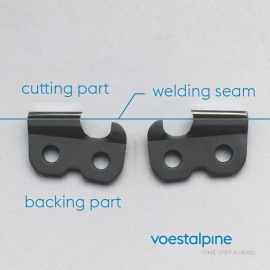

The links in a saw chain for motorised chainsaws, in particular for cutting wood are usually made out of low-alloy quenched and tempered steel. The edge retention of such types of saw chains is low, however. A considerable benefit is achieved by using saw chains made of composite materials. The cutting elements in these saw chains consist of two materials appropriate for the requirements, which are welded together using either a laser beam or an electron beam to form a compound material. An unbreakable steel alloy is used for the backing part and a resilient high-speed steel alloy is used for the cutting part, which is welded to the backing part. Such types of saw chain are described for example in European Patent application EP0592389B1 or in German Patent application DE4303004C2 or DE102010011837A1.

New backing material – a world-wide first

Using a backing material permitting quenching and tempering on the one hand displays a sufficiently high resistance to wear for high-speed steel, and on the other hand has a quenched and tempered backing part with high tensile strength and the potential for the heat treatment required. The steel material of the backing component in a quenched and tempered condition displays a hardness of up to 750 HV and a tensile strength of up to 2,500 MPa. The backing material now also fulfils the increased demands on tensile strength for the cutting element in accordance with the invention, which arise from the increased working times for the saw chain between sharpening and inspection, resulting from using high-speed steel for the cutting element. The cutting-edge life for these saw chains exceeds the cutting-edge life of normal chains made of carbon steel many times over, and they are therefore especially suitable for mechanical applications.

The invention on hand concerns the cutting element for a saw chain and a saw chain equipped with such types of cutting elements for motorized chainsaws.

The links in a saw chain for motorised chainsaws, in particular for cutting wood are usually made out of low-alloy quenched and tempered steel. The edge retention of such types of saw chains is low, however. A considerable benefit is achieved by using saw chains made of composite materials. The cutting elements in these saw chains consist of two materials appropriate for the requirements, which are welded together using either a laser beam or an electron beam to form a compound material. An unbreakable steel alloy is used for the backing part and a resilient high-speed steel alloy is used for the cutting part, which is welded to the backing part. Such types of saw chain are described for example in European Patent application EP0592389B1 or in German Patent application DE4303004C2 or DE102010011837A1.

New backing material – a world-wide first

Using a backing material permitting quenching and tempering on the one hand displays a sufficiently high resistance to wear for high-speed steel, and on the other hand has a quenched and tempered backing part with high tensile strength and the potential for the heat treatment required. The steel material of the backing component in a quenched and tempered condition displays a hardness of up to 750 HV and a tensile strength of up to 2,500 MPa. The backing material now also fulfils the increased demands on tensile strength for the cutting element in accordance with the invention, which arise from the increased working times for the saw chain between sharpening and inspection, resulting from using high-speed steel for the cutting element. The cutting-edge life for these saw chains exceeds the cutting-edge life of normal chains made of carbon steel many times over, and they are therefore especially suitable for mechanical applications.