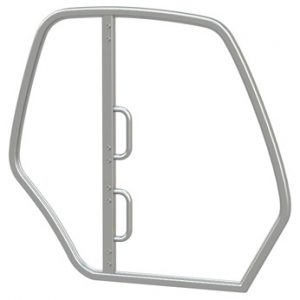

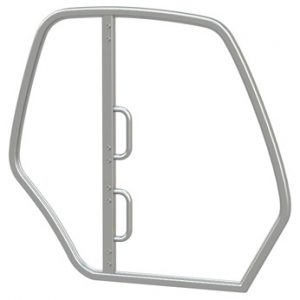

The Profile Manipulation division specialises in the process of cold bending, forming & sweeping of metal sections or tubes.

At the cutting edge of metal forming we have the capability to produce virtually any manipulated product from a limitless range of profile shapes, tubes and standard sections. For applications such as: safety and roll over protection systems for agricultural vehicles, excavators, construction vehicles and fork lift trucks.

Contact Custom Roll-Forming Division

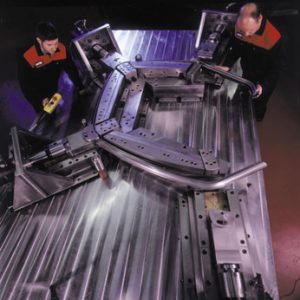

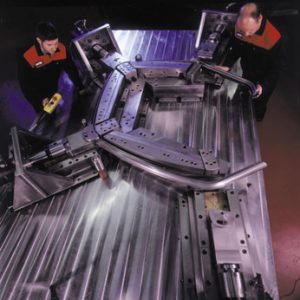

Mandrel Bending & Forming

The process of mandrel bending is used when the geometry of the profile is to remain consistent during and after bending.

A precision mandrel of the same profiles is held within the profile during bending to prevent the profile from collapsing, whilst external tooling is applied to prevent the profile from distorting.

Mandrel bending allows tubes to be bent to ever decreasing radii without deformation.

Sweep Bending

Sweep bending is used for producing a continuous sweep within part or all of a profile. This can be performed as a single operation or in conjunction with mandrel bending.

Sweep bending requires a former to be used for the profile to follow the desired curve.

Ring Rolling

Ring Rolling is generally the simplest form of bending profiles and tubes. The ring rolling process relies on a set of three rolls whereby the middle roll is used to apply pressure against the other two, inducing a curve as the profile is passed through.

Ring rolling can be used to produce consistent curves on parts of profiles and/or complete circular hoops.