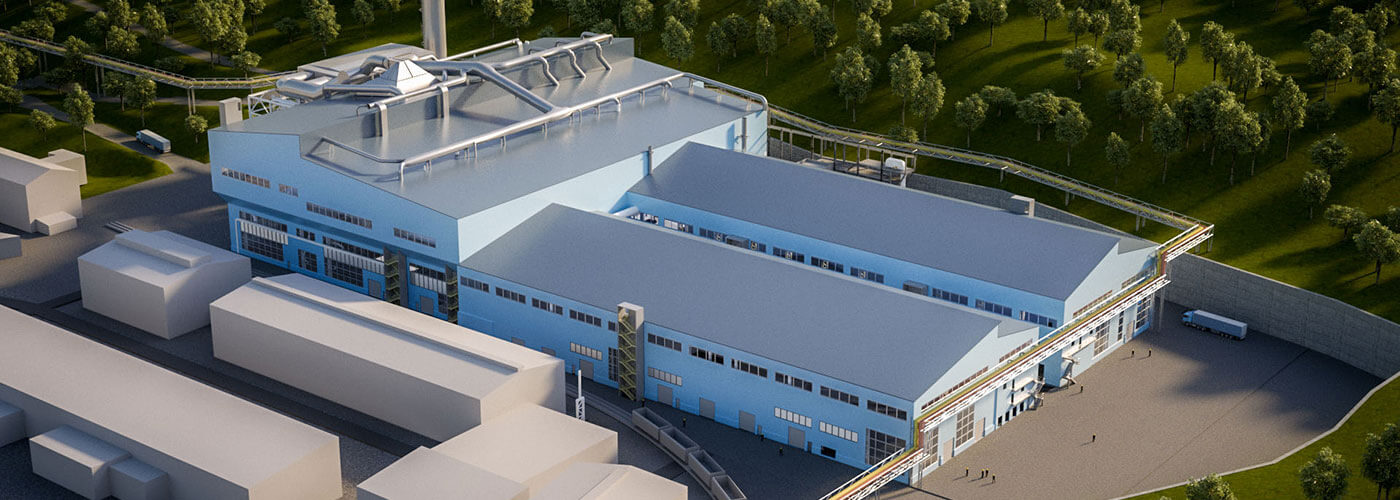

World’s most advanced special steel plant

Most modern stainless steel plant in the world

In the last few weeks, after five years of construction, the first melts in the electric arc furnace have been successfully carried out in the new stainless steel plant. This means that the process from melting the scrap in the electric arc furnace to pouring the liquid steel into the molds could be carried out for the first time. With this step, an important milestone has been reached as part of the hot commissioning of the new stainless steel plant. In the next few months more will be added all the time

Tests carried out and process steps optimized to ensure a stable production process in the future

to be able to guarantee. With the state-of-the-art plant, which will produce special steels for the international aviation, oil and gas, automotive and toolmaking industries, we are setting a technological milestone in terms of automation and sustainability here at the site.

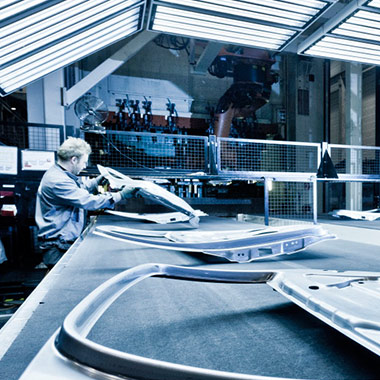

New standards in digitization

The state-of-the-art facility sets international standards in terms of digitized production processes. Around 8,000 pieces of process data are continuously recorded, implemented and evaluated in parallel. The high degree of digitization requires highly trained specialists who control the machines and evaluate data. The corresponding qualification of the employees in the areas of robotics, sensor technology or data analysis takes place via an in-house competence center for digitization. The new stainless steel works will secure around 3,500 jobs at the Styrian voestalpine sites in Kapfenberg and Mürzzuschlag.

Use of sustainable future technologies

Another focus is on environmentally friendly and resource-saving steel production. The new stainless steel plant sets new benchmarks worldwide in terms of sustainability and energy efficiency. This investment is therefore also an essential part of the overall sustainability strategy. The electric arc furnace – the heart of the plant – is operated 100 percent with electricity from renewable energy sources. Thanks to closed cooling circuits, the amount of cooling water required can be reduced by up to 90 percent. In addition, an efficient recovery system ensures that the heat generated is used internally and fed into the public district heating network.

After the new plant has been commissioned, the existing plant will be shut down.

Technology & innovation leader “Most modern stainless steel plant in the world”

With the stainless steel plant at the location of the voestalpine group company Böhler Edelstahl in Kapfenberg, the most modern plant in the world is being built. It is intended to further expand voestalpine’s leading international position as a technology and capital goods group with high-end products for the most demanding customer segments.

Here you will find all information about our construction project:

| LINKS |