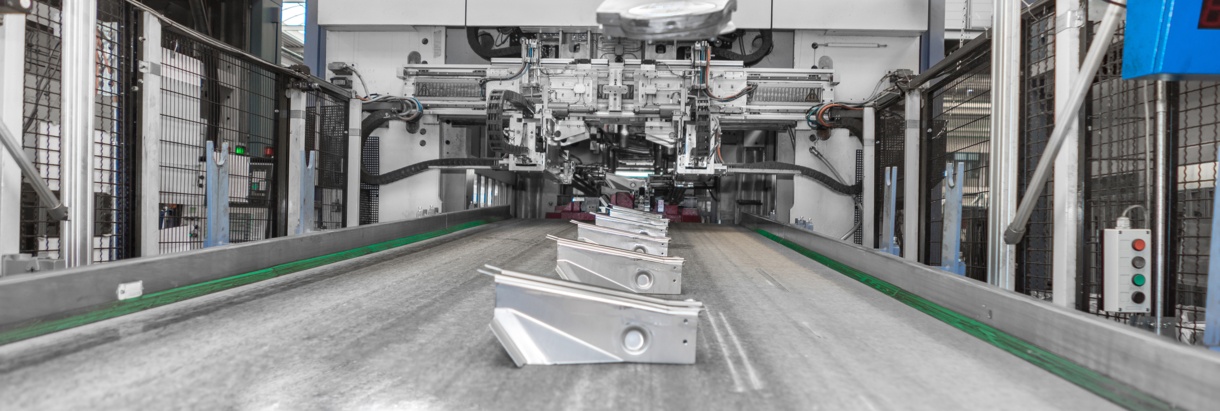

Cold stamping production location

voestalpine Automotive Components Böhmenkirch GmbH & Co. KG develops and produces ready-to-install stamped and formed parts as well as safety and impact protection components for all notable car manufacturers. Parts for the energy supply and household appliance markets complete the product portfolio. With about 150 employees, the direct supplier works with state-of-the-art progressive and transfer technologies and innovative production processes.

Competences

With state-of-the-art progressive and transfer technologies and innovative production processes, we produce components for the automotive, energy supply and household appliance industries.

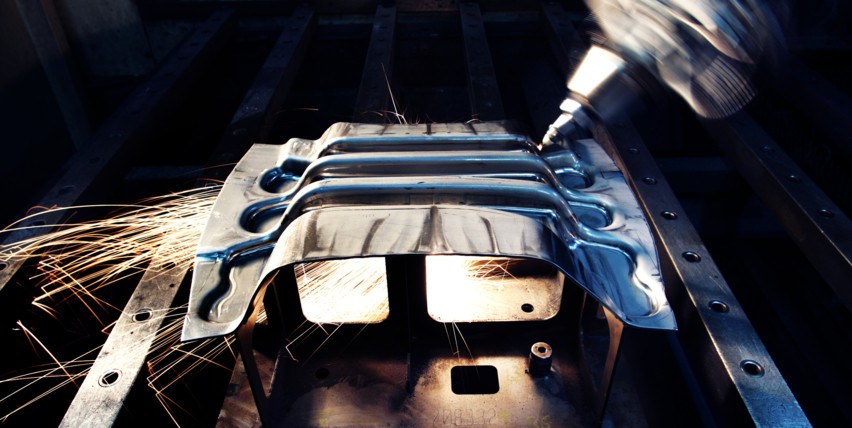

- MIG/MAG/TIG

Resistance welding processes

Capacitor discharge welding

Mechanical processes

Swaging

- Toxing

- Riveting

- 125 t to 800 t pressing force

- Function integration due to tool-integrated processes

- Drawn parts with the highest degree of formability

- Range of materials

- Max. sheet thickness: 4 mm from the coil

- Max. coil width: 1.3 m

- Max. table length: 4 m

- Max. table width: 2 m