Production location for cold stamping, hot forming and after-market solutions

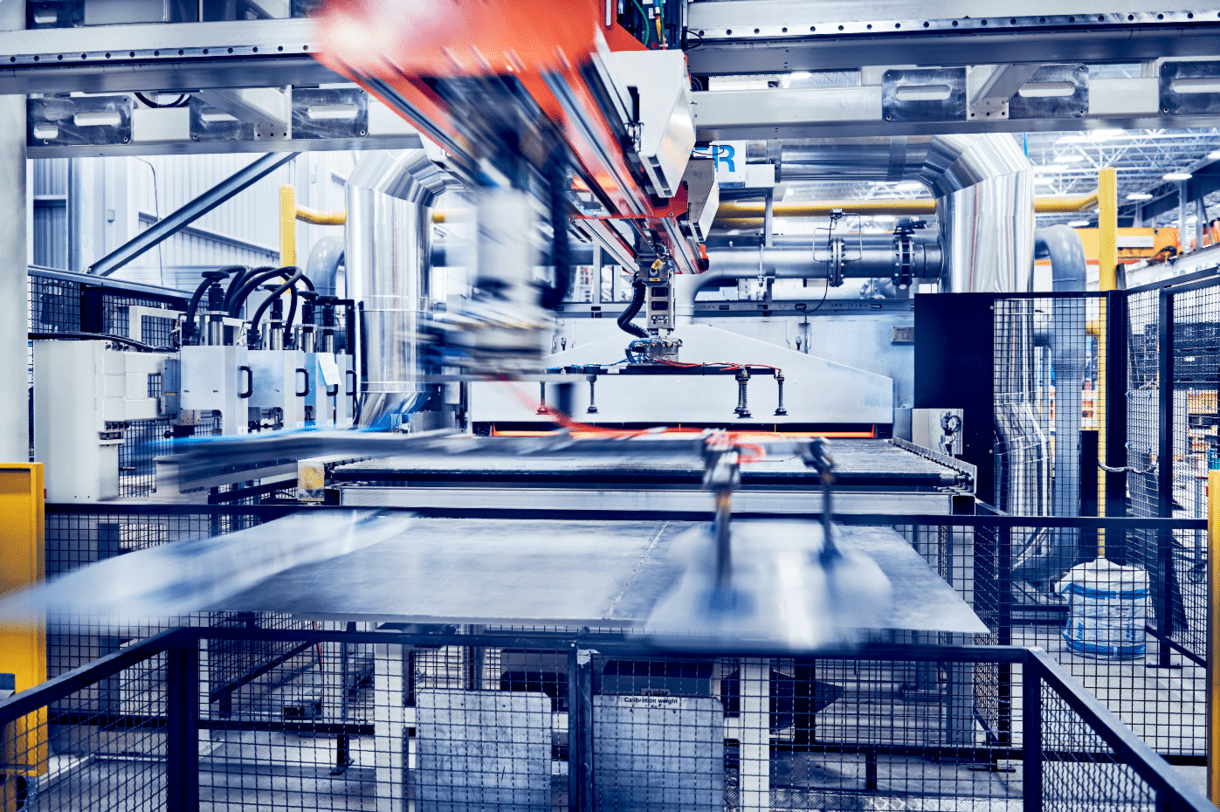

voestalpine Automotive Components Cartersville Ilc. is the US base for supplying ultra-high strength body-in-white components for premium car manufacturers. The scope of work covered at the site ranges from press parts to assemblies to hot-formed and laser-welded blanks. The new plant will primarily produce high quality automotive components (body-in-white parts):

- Assemblies made of phs-ultraform® parts

- Stamped parts

- Hot-formed phs-ultraform® components

The state-of-the-art plant is the first production location of voestalpine for the lightweight construction of ultra-high strength automotive components in the USMCA area. The Cartersville site is an important step for voestalpine, enabling it to provide high-quality support to local customers. The geographical proximity to customers is also important, with many products being subject to a tight time frame between production and processing.

voestalpine Automotive Components Cartersville llc. is the anchor tenant at Highland 75 Industrial Park, Bartow County, Georgia. The voestalpine site in Georgia has developed rapidly since opening in spring 2014. As a rapidly growing company, we are always looking for qualified personnel to join us. You can find information about career opportunities at voestalpine Automotive Components Cartersville llc. in the career section.