Machinery Industry

There can be no compromises in the selection of machine materials when their high performance is at stake under the harshest conditions. alform® provides convincing solutions for a wide variety of machines.

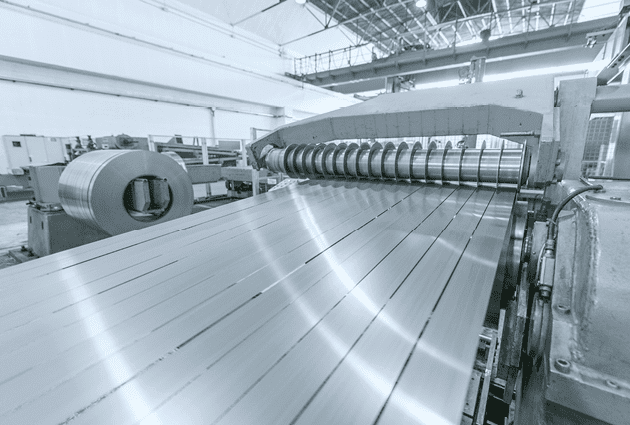

Processing Industry

Whether for cold rollers, the tube and section industry, steel service centers or steel trade entities, the excellent properties of alform® provide unique solutions for the processing industry with uncompromising efficiency.